Manually-controlled shutter valve

A manual control, louver technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of poor stability and sealing, unfavorable working conditions, unreasonable design, etc., and achieve flexible, reliable and stable opening and closing actions. The effect of precision, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

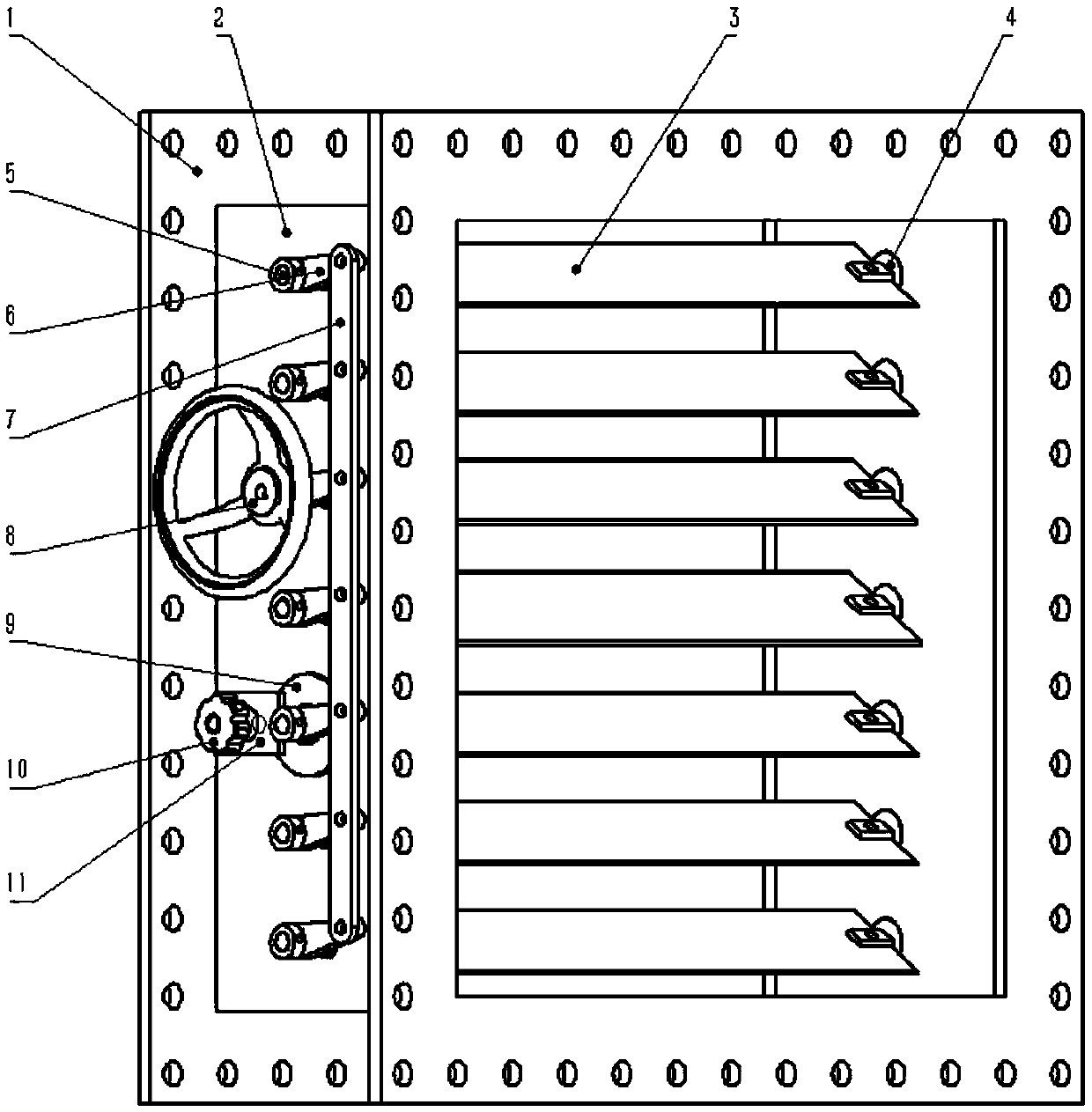

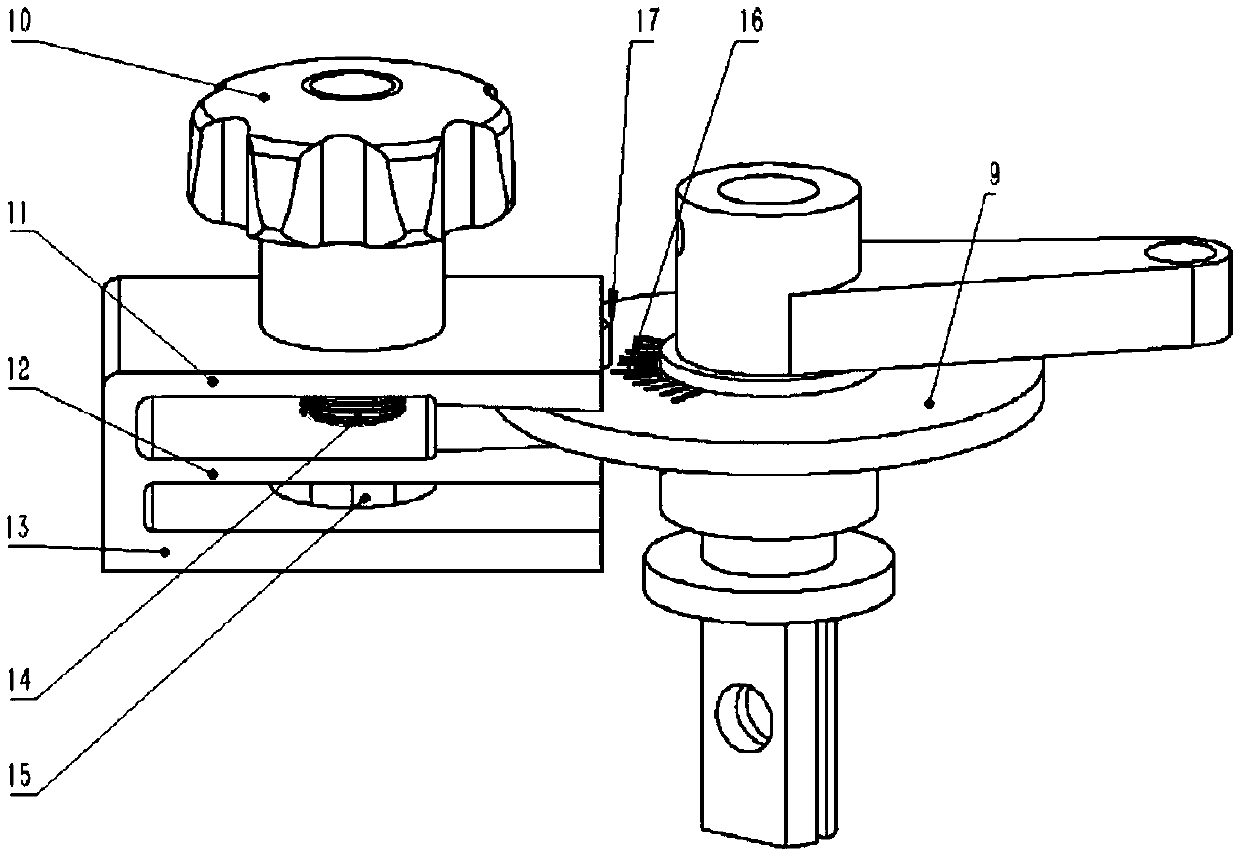

[0029] see Figure 1 to Figure 3 A manually controlled louver valve provided by the present invention includes a flange 1, a valve body 2, a valve plate 3, a right valve shaft 4, a left valve shaft 5, a manual drive mechanism and a control assembly, and the manual drive mechanism includes a crank 6, Connecting rod 7 and large handwheel 8, control assembly comprises wheel disc 9, small handwheel 10, upper clamping plate 11, lower clamping plate 12, base 13, spring 14, threaded rod 15, opening gauge 16 and wedge block 17.

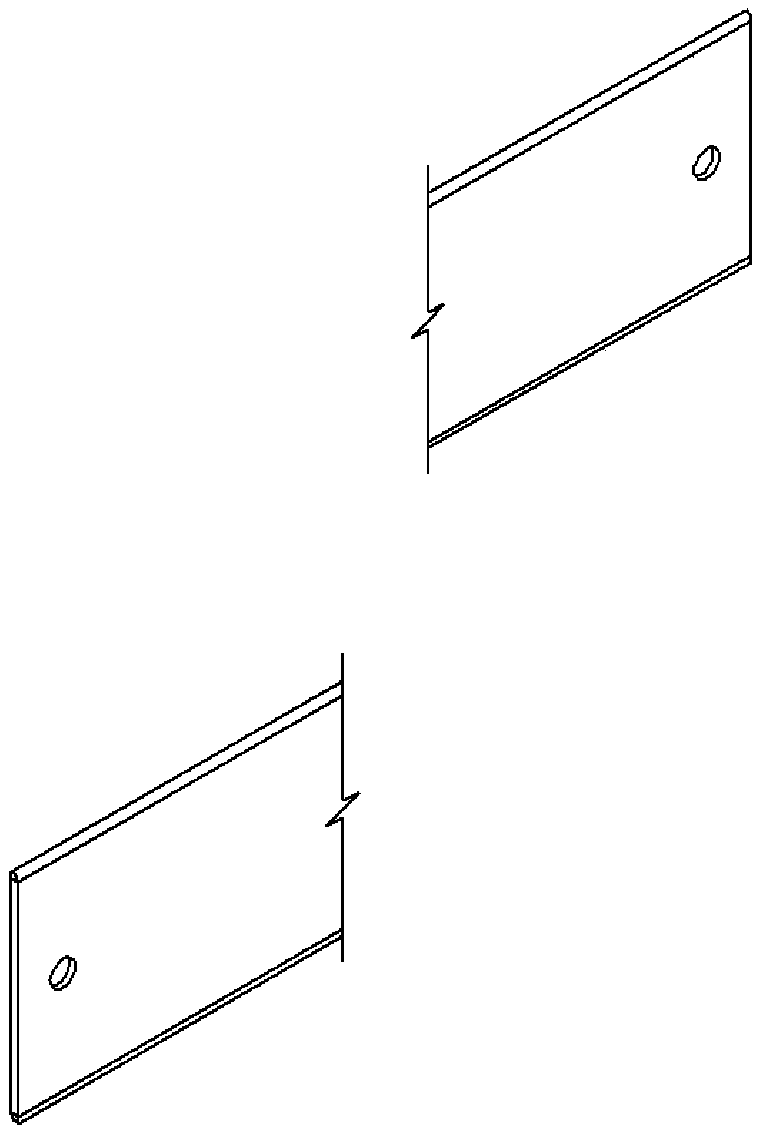

[0030] The flange 1 is connected with the valve body 2; there are several stepped holes symmetrically opened on both sides of the valve body 2, and a sleeve is installed in each stepped hole; the part of the valve shaft located inside the valve body 2 is radially opened with The bolt hole is axially provided with a groove equal to the thickness of the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com