Ball valve

A technology for ball valves and valve stems, which is applied to valve devices, cocks including cut-off devices, engine components, etc., and can solve problems such as easily damaged ball valves and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

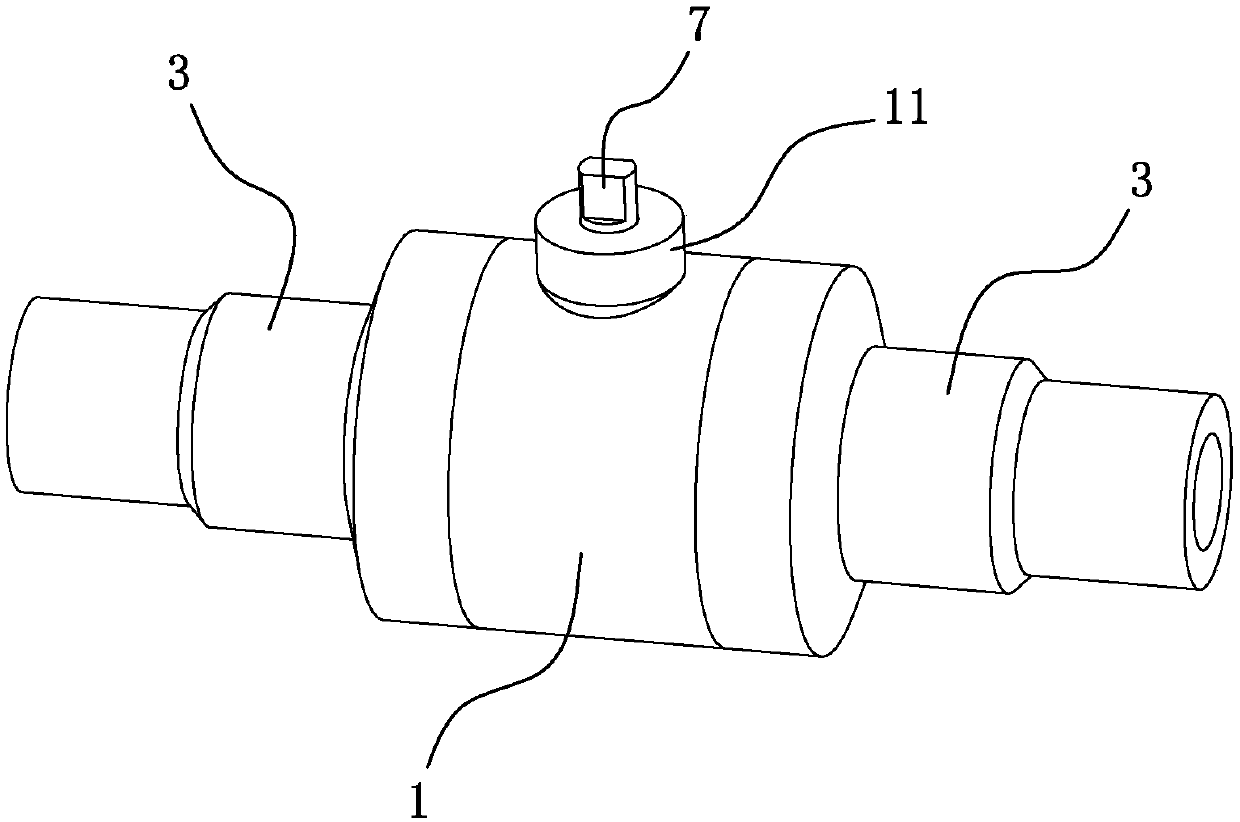

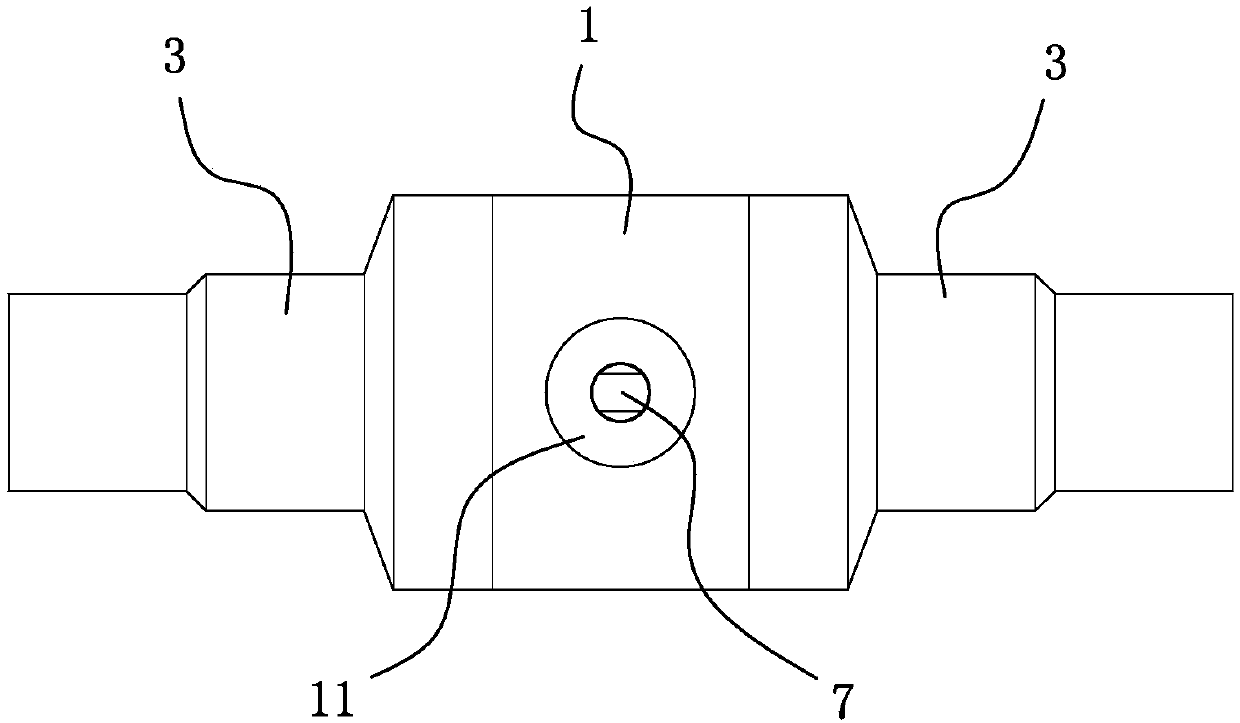

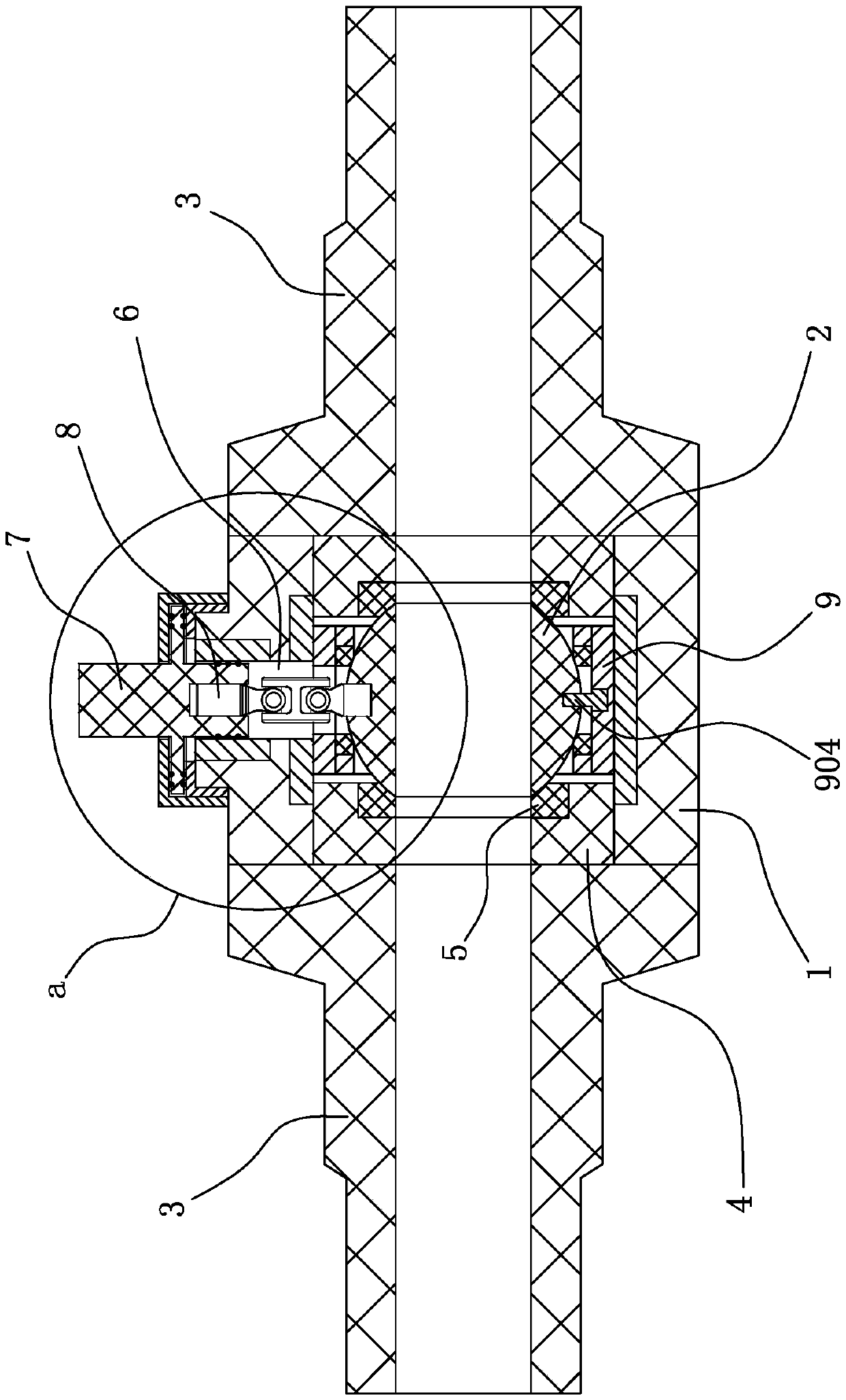

[0035] see Figure 1 to Figure 11 , a ball valve described in this embodiment at least includes a valve seat 1, a valve ball 2 disposed in the valve seat 1, and two connecting pipes 3 disposed on both sides of the valve seat 1, and each side of the valve ball 2 passes through a positioning Seat 4 is clamped and positioned, and the side facing the valve ball 2 of the two positioning seats 4 is provided with a first sealing ring 5 that fits and seals with the outer wall of the valve ball 2, and a valve stem is provided on the upper side of the valve seat 1 through the inner and outer walls Through hole 6.

[0036] The valve seat 1 is also provided with a valve stem 7 and a double-joint universal joint 8, the lower section of the valve stem 7 is located in the valve stem through hole 6, and the valve stem 7 and the valve stem through hole 6 are realized by a rotating sealing mechanism. Rotational sealing fit, the said rotating sealing mechanism is that the valve stem 7 is sleeve...

Embodiment 2

[0043] see Figure 12 to Figure 15 , this embodiment further makes the following improvements on the basis of embodiment one:

[0044] It also includes a valve stem locking mechanism 12. The valve stem locking mechanism 12 includes a positioning sleeve 1201 and a lifting ring 1202. The positioning sleeve 1201 is coaxially embedded in the valve stem through hole 6. The The valve stem 7 realizes rotation and sealing cooperation with the valve stem through hole 6 through the positioning sleeve 1201, and several O-rings 705 are set on the valve stem 7, and the O-rings 705 are in rotation and sealing cooperation with the inner wall of the positioning sleeve 1201; The positioning sleeve 1201 is provided with several slideways 1203 and several air pressure passages 1204. The slideways 1203 correspond to the air pressure passages 1204 one by one. The slideways 1203 are arranged vertically. The opening at the lower end communicates with one end of the corresponding air pressure channe...

Embodiment 3

[0047] see Figure 16 to Figure 17 , this embodiment further makes the following improvements on the basis of embodiment one:

[0048] It also includes a valve stem sealing mechanism 13, the valve stem sealing mechanism 13 includes a positioning sleeve 1201 and an inflatable sealing ring 1301, the positioning sleeve 1201 is coaxially embedded in the valve stem through hole 6, the valve The rod 7 realizes rotational sealing cooperation with the valve stem through hole 6 through the positioning sleeve 1201, and several O-rings 705 are set on the valve rod 7, and the O-rings 705 are rotationally and sealingly matched with the inner wall of the positioning sleeve 1201; The inner wall ring of the positioning sleeve 1201 is provided with a sealing ring limiting groove 1302, and the inflatable sealing ring 1301 is set in the sealing ring limiting groove 1302 and the ring is set on the outside of the valve stem 7; the positioning sleeve 1201 is provided with an inflation channel 1303 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com