Method for detecting surface viscosity of prepreg tows for automatic tow placement

A surface sticky, automatic wire laying technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., to avoid the influence of human errors, ensure accuracy and guidance, and test methods are simple and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

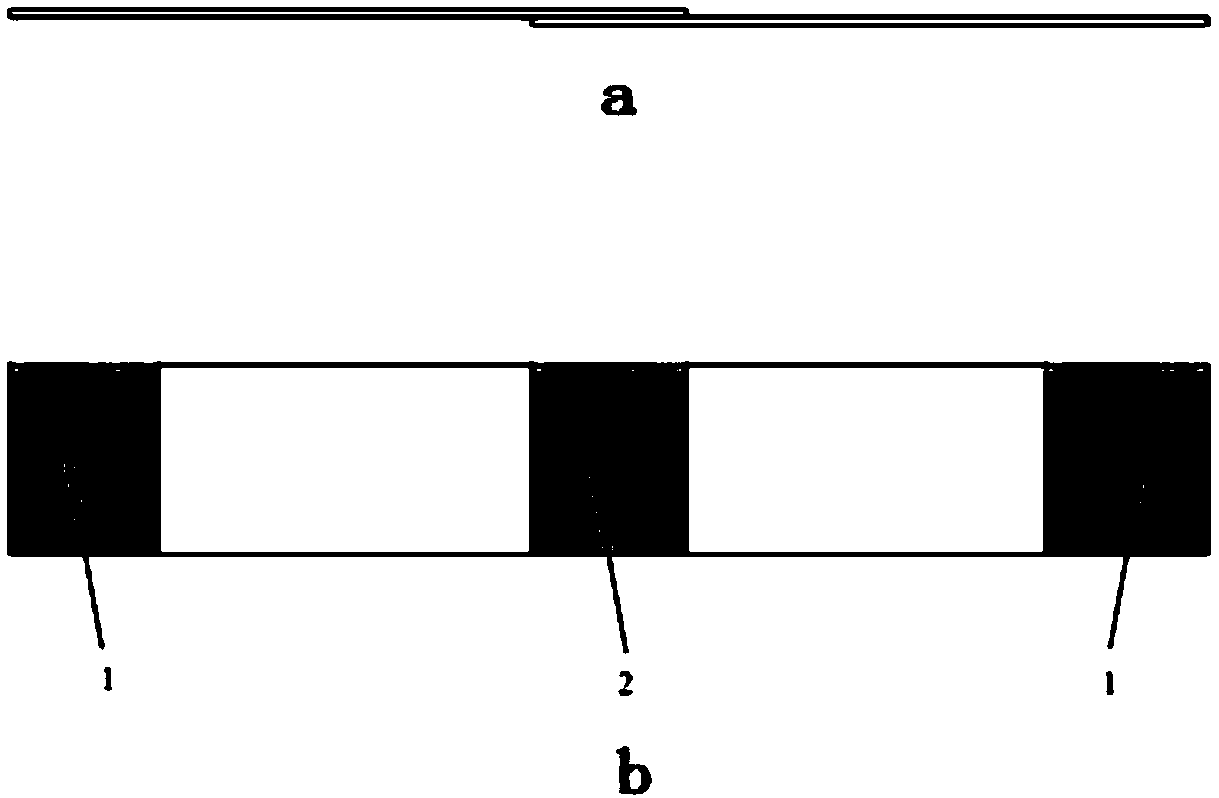

[0024] Put the two prepreg tows according to the figure 1 The method and size of the prepreg are manually pre-bonded first. The length of the bonding area 2 of the two prepreg tows is 40mm, and the direction of the main axis should be the same as that of the carbon fibers in the prepreg tows. Then put the bonded area into a mechanical hot-pressing platform for hot-pressing overlapping, and use a polytetrafluoroethylene release cloth to isolate the prepreg tow and the hot-pressing platform. The temperature of the lap joint is 24°C, the pressure is 0.1MPa, and the time is 2min. The obtained surface adhesion test sample is symmetrically clamped on the clamp of the tensile tester, and the distance between the end of the clamping area 1 of the clamp and the nearest overlapping end is 100 mm. Start the tensile tester, and the pull-off failure load of the prepreg tow sample is 198.2N.

Embodiment 2

[0026] Put the two prepreg tows according to the figure 1 The method and size of the prepreg are manually pre-bonded. The length of the bonding area 2 of the two prepreg tows is 35mm, and the direction of the main axis should be the same as that of the carbon fibers in the prepreg tows. Then put the bonding area into a mechanical heat press platform for heat press lapping, and use PE film to isolate the prepreg tow and the heat press platform. The temperature of the lap joint is 60°C, the pressure is 0.6MPa, and the time is 10min. The obtained surface adhesion test sample is symmetrically clamped on the clamp of the tensile tester, and the distance between the end of the clamping area 1 of the clamp and the nearest overlapping end is 80 mm. Start the tensile tester, and the pull-off failure load of the prepreg tow sample is 465.3N.

Embodiment 3

[0028] Put the two prepreg tows according to the figure 1 The method and size of the prepreg are manually pre-bonded first. The length of the bonding area 2 of the two prepreg tows is 60mm, and the direction of the main axis should be the same as that of the carbon fibers in the prepreg tows. Then put the bonded area into a mechanical hot-pressing platform for hot-pressing overlapping, and use a polyester film to isolate the prepreg tow from the hot-pressing platform. The temperature of the lap joint is 10°C, the pressure is 0.4MPa, and the time is 3min. The obtained surface adhesion test sample is symmetrically clamped on the clamp of the tensile tester, and the distance between the end of the clamping area 1 of the clamp and the nearest overlapping end is 150 mm. Start the tensile tester, and the pull-off failure load of the prepreg tow sample is 135.N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com