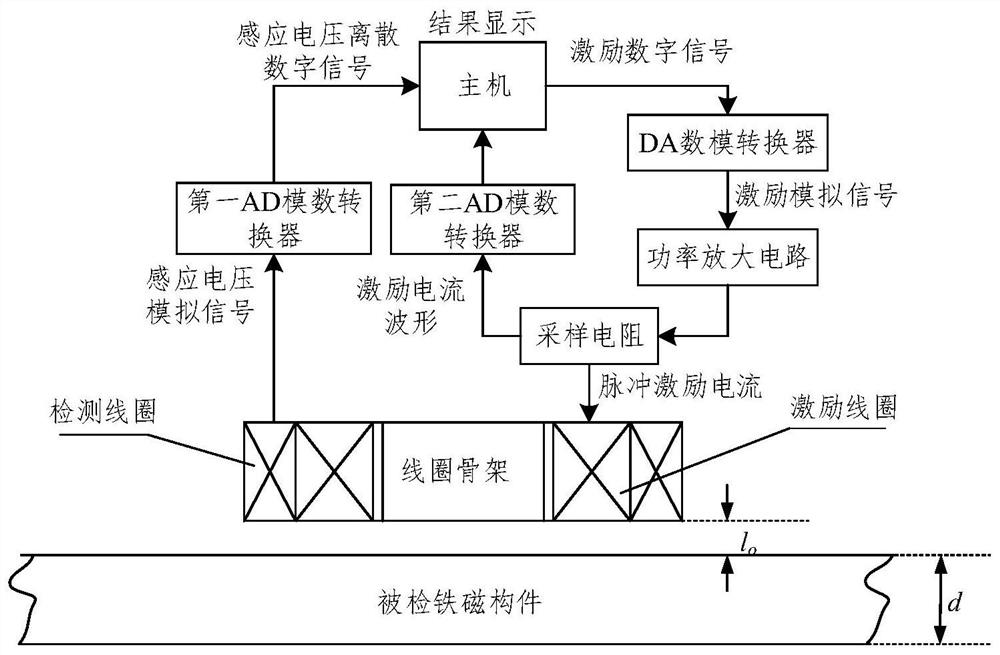

A pulsed eddy current detection method and detection device for the conductivity of ferromagnetic metal materials

A ferromagnetic metal and electrical conductivity technology, which is applied in the field of pulsed eddy current testing methods and testing devices for electrical conductivity of ferromagnetic metal materials, can solve problems such as large errors and poor repeatability of testing results, so as to reduce the influence, improve the technological level, and improve the The effect of precision and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

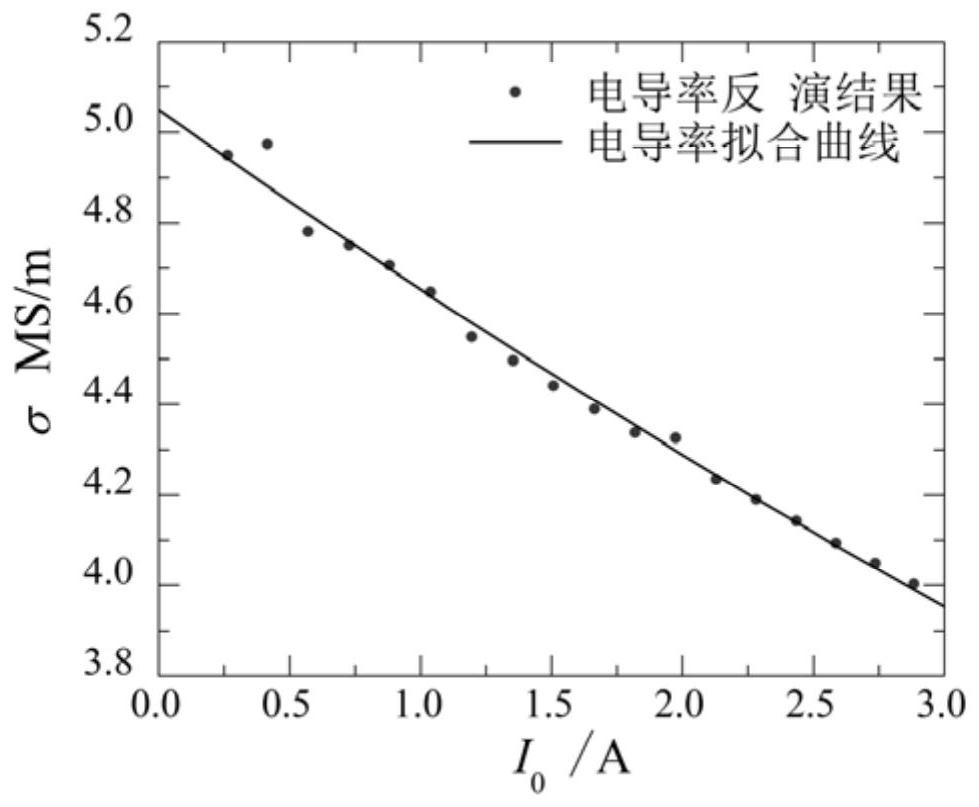

[0080] An example of conducting a conductivity test on a ferromagnetic member by the method of the present invention is given below.

[0081] The tested ferromagnetic components are three cylindrical steel test blocks with a diameter of 100mm and a thickness of 6mm, and the materials are 20# steel, 45# steel and Q235 steel respectively.

[0082] Place the coil probe above the center of the three tested steel test blocks in turn, keep the lift-off distance of the coil probe unchanged at 5mm, and the pulse excitation current amplitude I 0 Take 0.2A as a step, gradually increase from 0.2A to 3.0A, first obtain the pulse eddy current detection signal according to the SAP step in the present invention, and then use the detection signal to establish a least squares problem according to the PIP step, and obtain different amplitude pulse current excitations The inversion results of the conductivity and relative permeability of the ferromagnetic component under test are plotted as foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com