Battery Pack Manufacturing System for Secondary Batteries

A technology for manufacturing a system and a secondary battery, applied in the field of battery devices, can solve the problems of reduced productivity, large operation time, and long moving distance of the workbench, and achieves improved productivity, shortened operation time, and reduced manufacturing time and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, preferred embodiments of the secondary battery pack manufacturing system according to the present invention will be described in detail with reference to the accompanying drawings.

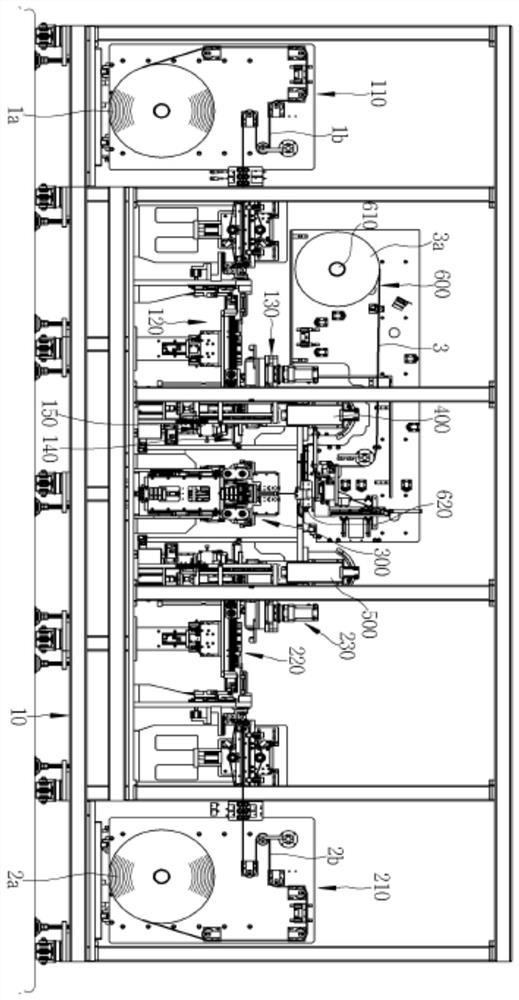

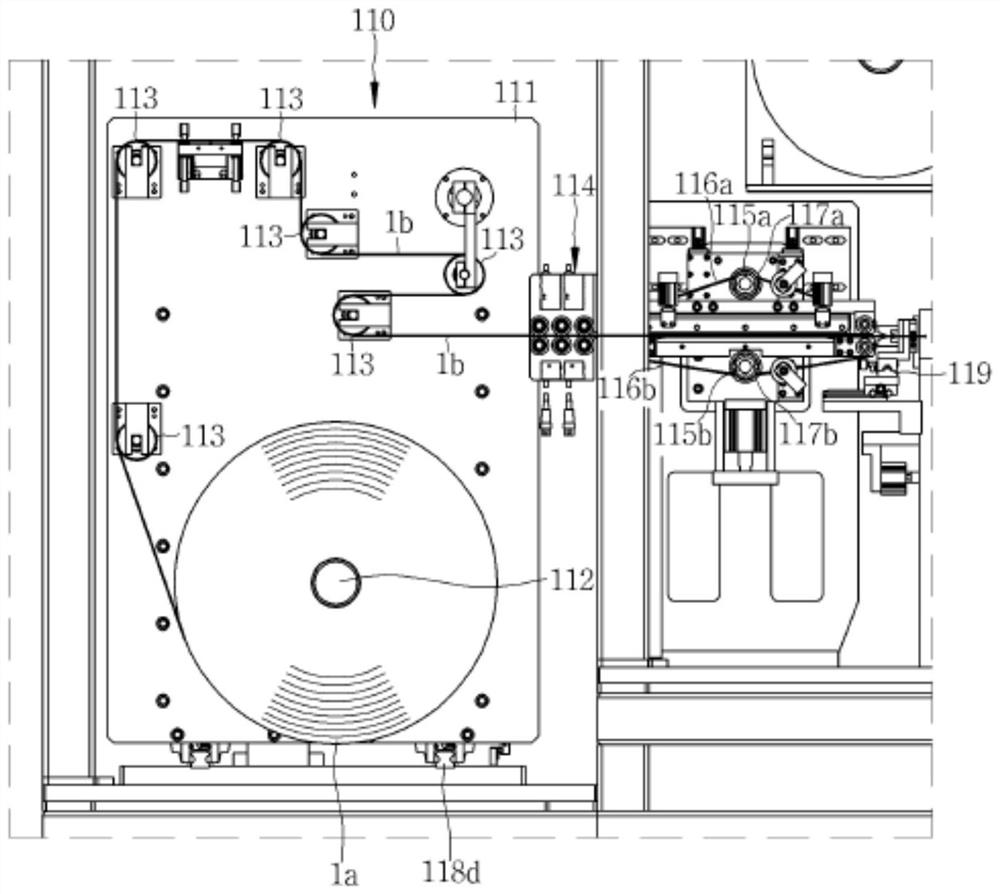

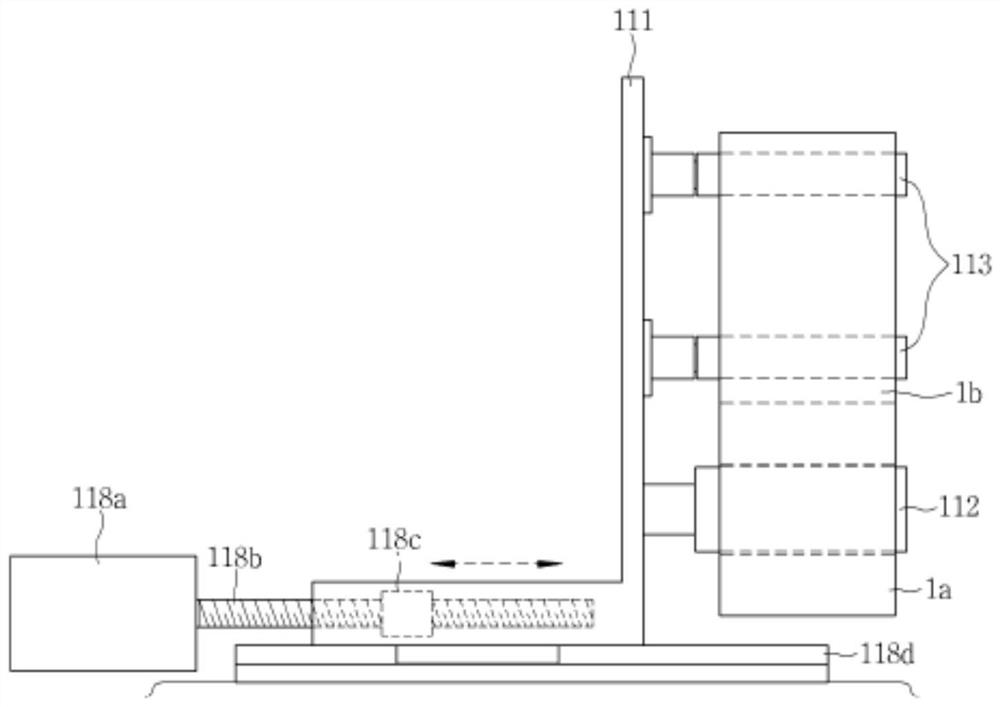

[0037] First, refer to figure 1, according to an embodiment of the present invention, the secondary battery battery pack manufacturing system is used as an equipment for manufacturing a secondary battery by sequentially stacking an anode plate (anode electrode), a separator (separation membrane) and a cathode plate (cathode electrode), including: a body 10 An anode supply part 110, which is equipped with an anode reel 1a, and the anode reel 1a is coiled with an anode film 1b; an anode cutting part 120, which cuts the anode film 1b released from the anode reel 1a and transferred to a certain size the anode plate 1; the first alignment workbench 140, which adjusts the position of the anode plate 1 cut off by the anode cutting part 120; the first view inspection part 150, which re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com