Electromagnetic booster stator coreless permanent magnet linear motor

A permanent magnet linear motor, ironless technology, applied in electromechanical devices, electrical components, propulsion systems, etc., can solve the problems of large magnetic flux leakage, large volume and weight, and large instantaneous output of permanent magnets, and achieve air gap magnetic density and High thrust density, increased air gap magnetic density, and increased thrust density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

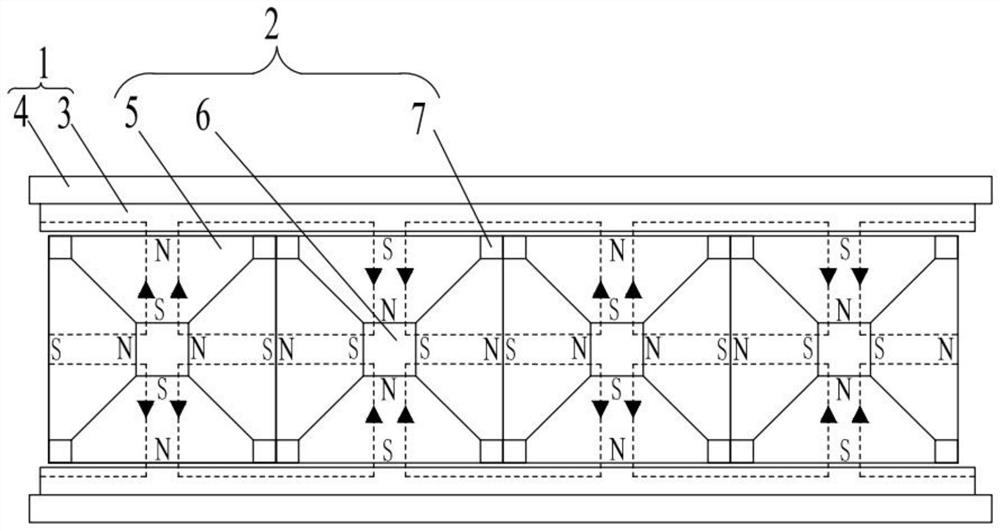

[0017] Such as Figure 1-5 , the stator coreless permanent magnet linear motor for electromagnetic boosting of the present invention includes a stator 1 and a mover 2 that moves relative to the stator 1, the stator 1 is a coreless structure, there is an air gap between the stator 1 and the mover 2, and the stator 1 There are two groups, symmetrically placed on the upper and lower sides of the mover 2, and the mover 2 is in the middle.

[0018] Stator 1 includes winding 3 and winding frame 4, such as Figure 5 As shown, the winding 3 is filled and fixed on the winding frame 4 with an adhesive with good performance. section, such as Figure 4 As shown, each winding frame 4 is connected with a non-magnetic conductive frame.

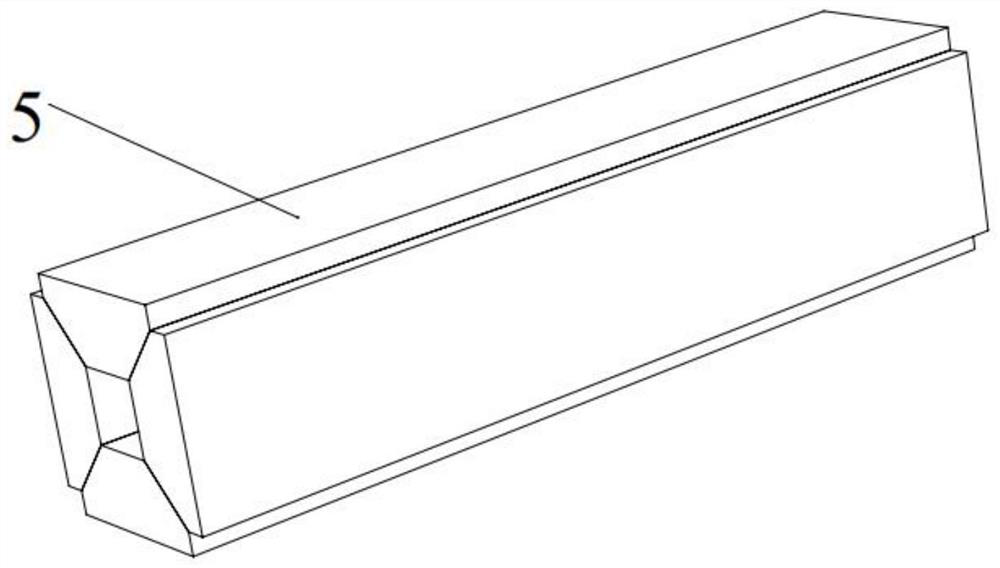

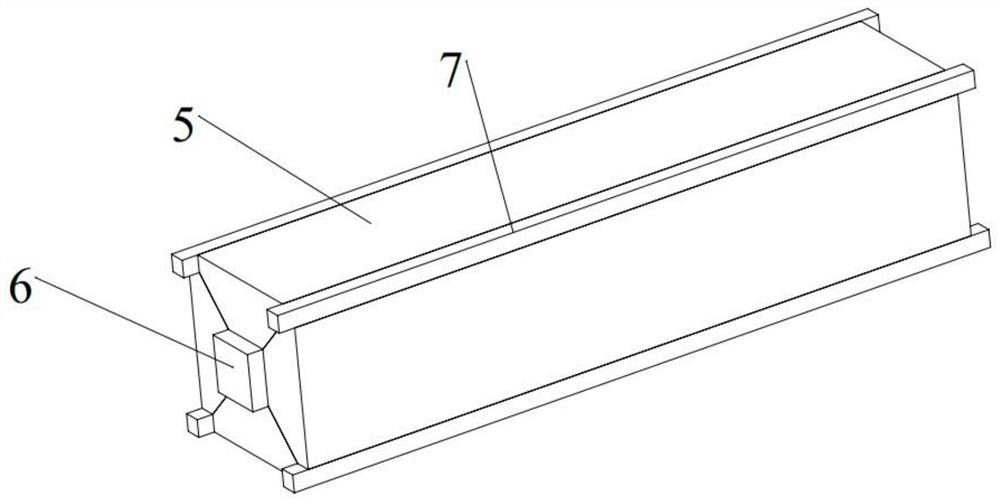

[0019] The mover 2 includes two pairs of poles, and each pair of poles includes two poles. Each adjacent two poles are closely matched, and each pole includes four permanent magnets 5, a magnetically conductive mover shaft 6 and a non-magnetically conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com