A preformed brazing coating material for rotary tiller

A rotary tiller, preformed technology, applied in welding/cutting media/materials, metal processing equipment, welding equipment, etc., can solve the problem of difficulty in positioning, temperature, timing, quantitative, and easy to generate harmful gases and residues. , the inability of quantitative coating, etc., to avoid the waste of brazing coating materials, improve work efficiency, and achieve the effect of high reliability of brazing coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

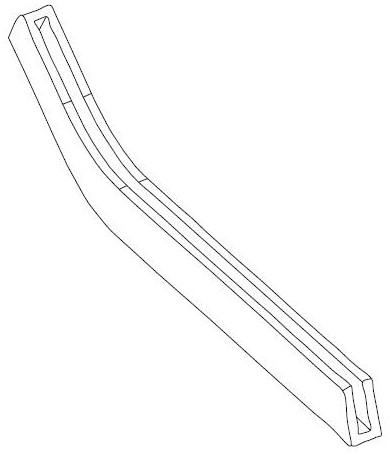

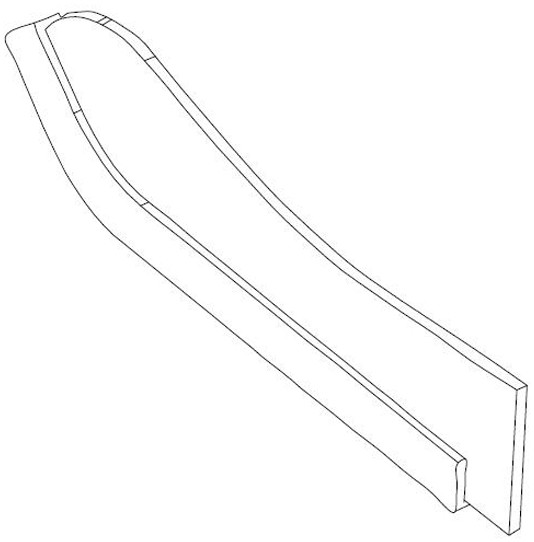

[0024] As shown in the accompanying drawings, a preformed brazing coating material for a rotary tiller is provided. The preformed brazing material is coated on the blade of the rotary tiller and forms a U-shaped knife sleeve in section. The inner cavity of the knife sleeve is Matching the blade of the rotary tiller, the raw materials for preparing the preformed brazing coating material are composed of the following components in parts by mass: 30-50 parts of tungsten carbide powder, 1-5 parts of flux-type binder, 0.1-1 part of toughening agent, 45-75 parts of nickel-based solder powder.

[0025] Further, the tungsten carbide powder is composed of tungsten carbide powder with a particle size of 40-60 mesh and tungsten carbide powder with a particle size of 160-200 mesh at a mass ratio of 1:5-1:2.

[0026] Further, the flux-type binder is composed of borax and water with a mass ratio of 3:1 to 2:1, and the preparation method of the flux-type binder comprises the following steps:...

Embodiment 2

[0037] A, prepare the mass parts of each component of the preformed brazing material: 25 parts of tungsten carbide powder, 1 part of flux type binder, 0.1 part of toughening agent, 73.9 parts of nickel-based solder powder; The dosage form binder is composed of borax and water with a mass ratio of 2:1;

[0038] B. The preparation method of brazing agent type binder includes the following steps: 1), weigh borax and water according to the mass ratio of borax: water is 2:1, add the above-mentioned water weighed into the weighed borax, add while adding Stir until the borax is completely dissolved, then stir for 3 to 5 minutes to form a uniform paste liquid; 2), put the paste liquid prepared in step 1) into the ceramic tank of the planetary ball mill for grinding, and the grinding speed of the planetary ball mill is 45r / min, the grinding time is 45-60min, and the flux-type binder is obtained;

[0039] C. Weigh 35 parts of tungsten carbide powder by mass, 1 part of flux-type binder,...

Embodiment 3

[0047] A, the mass fractions of each component for preparing the preformed brazing material are: 30 parts of tungsten carbide powder, 1.5 parts of flux type binder, 0.3 part of toughening agent, 68.2 parts of nickel-based solder powder; The dosage form binder consists of borax and water in a mass ratio of 2.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com