Proportional valve precise modeling based control method of asymmetric electric-hydraulic proportional system

An electro-hydraulic proportional and control method technology, which is applied in the field of machinery and electronics, can solve the problems that the stability cannot meet the field practicality, the small displacement tracking high-precision response, the adjustment range and precision are limited, and the problem of asymmetric response is simple. Effective, reduce debugging workload, and solve the effect of consistent response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

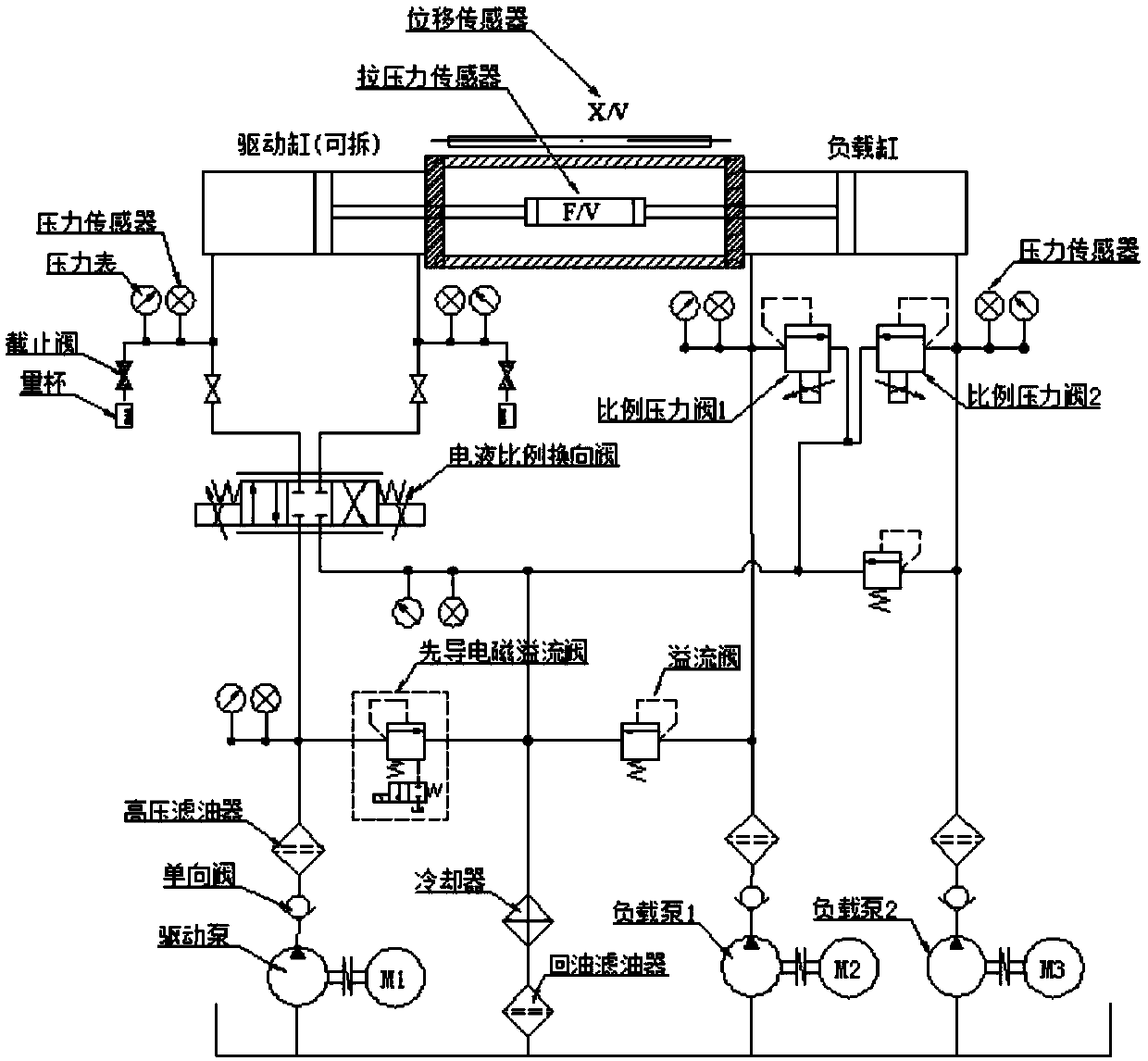

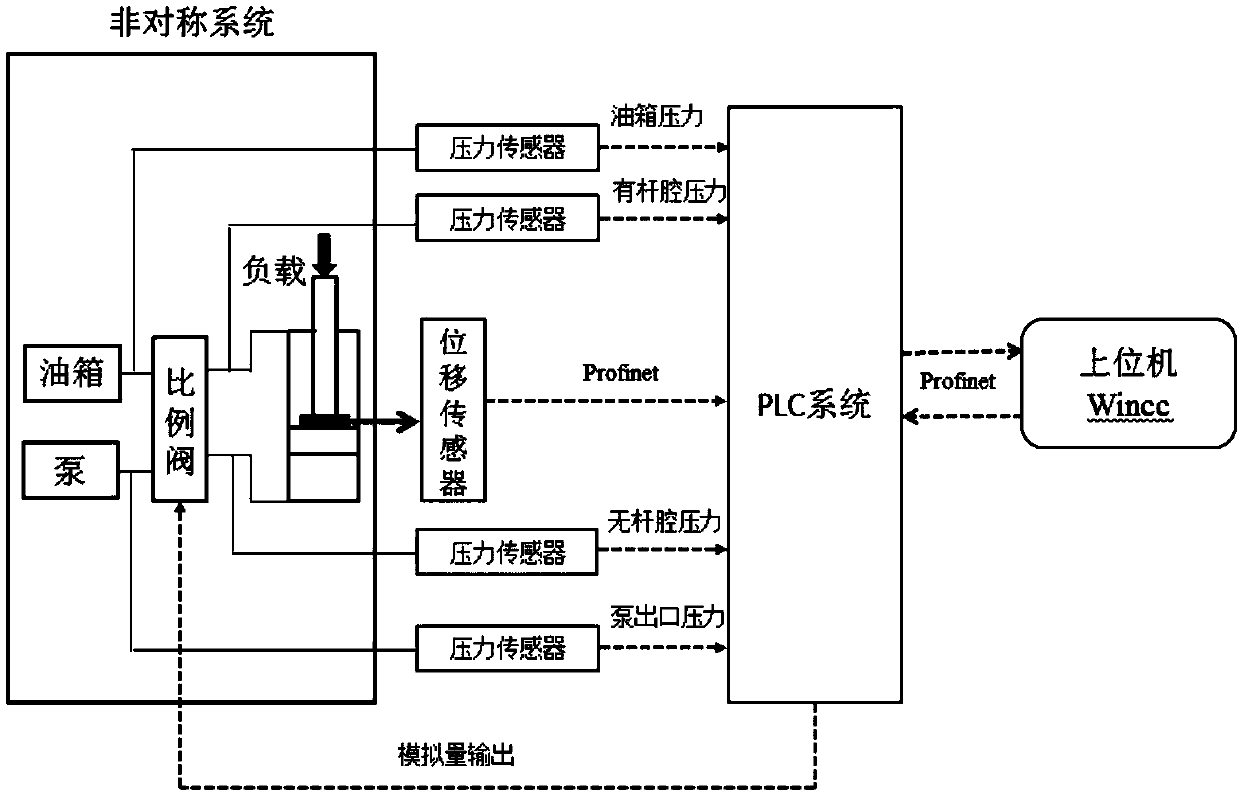

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] The present invention realizes based on following model:

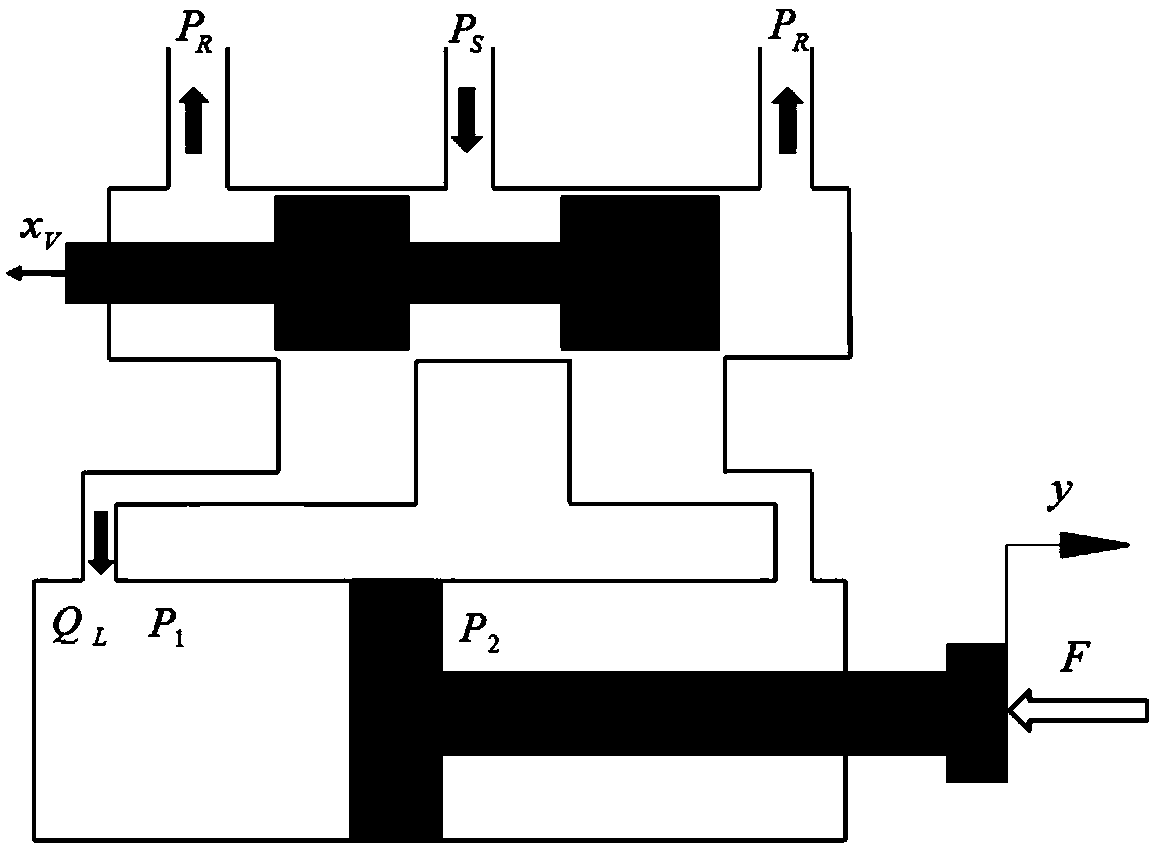

[0032] 1. Precise modeling of proportional valve

[0033]

[0034] Among them: ρ is the density of hydraulic oil, the unit is kg / m 3 ; w is the area gradient of the valve port, the unit is m; ν is the kinematic viscosity of the fluid, the unit is m 2 / s;x v The unit of opening of the valve port is m; C dt is the flow coefficient of the valve port under turbulent flow state, and the value is generally 0.7; k c is the coefficient related to the critical Reynolds number, 0.1R c ≤k c ≤0.2R c , where R c is the critical Reynolds number; Δp is the differential pressure at the valve port, in Pa.

[0035] 2. Ideal traffic

[0036] The ideal proportional valve output flow model is a linear model, as shown below:

[0037]

[0038] Where: P S Oil supply pressure for hydraulic pump,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com