Control method for asymmetric electric-hydraulic proportional system based on model transferring

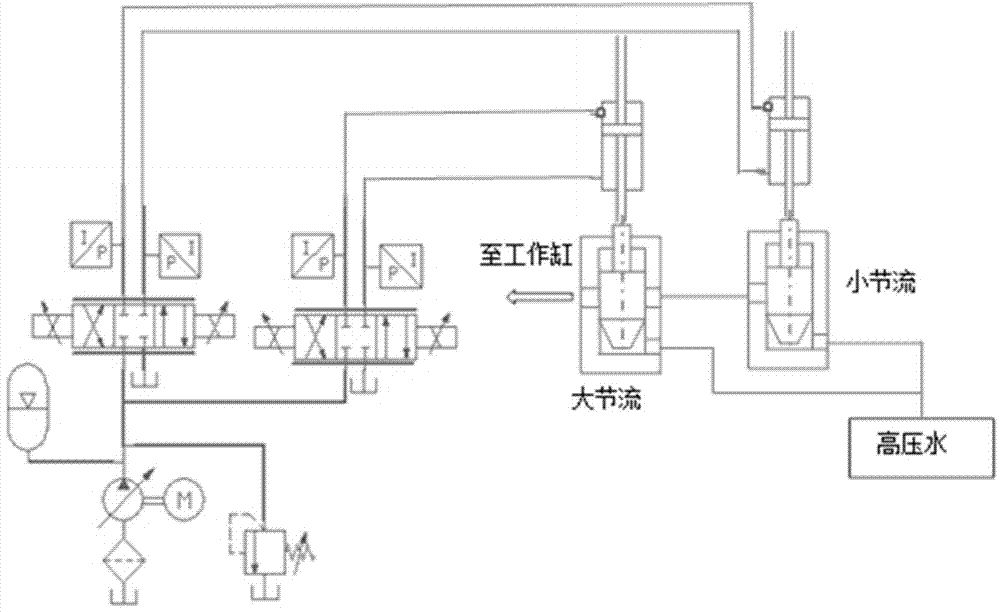

An electro-hydraulic proportional and model conversion technology, which is applied in fluid pressure actuation system testing, fluid pressure actuation devices, servo motors, etc., can solve problems such as difficult design and maintenance, high requirements for engineering and technical personnel, and complex control procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

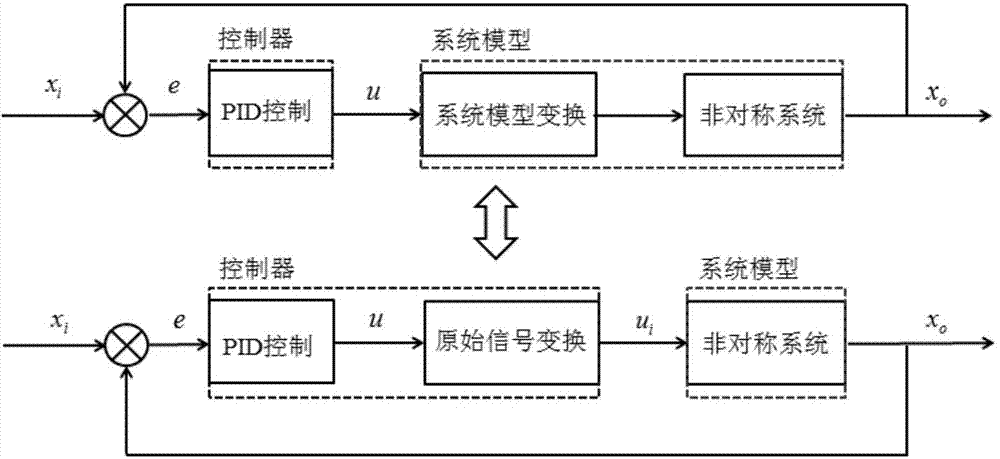

[0044] A control method for an asymmetric electro-hydraulic proportional system based on model transformation, which transforms the asymmetric mathematical model of the asymmetric electro-hydraulic proportional system into a symmetrical system model by using the transformation transfer function, and realizes the symmetrical transformation of the load flow model, making the use of When the controller is unified, the positive and negative motion responses are consistent;

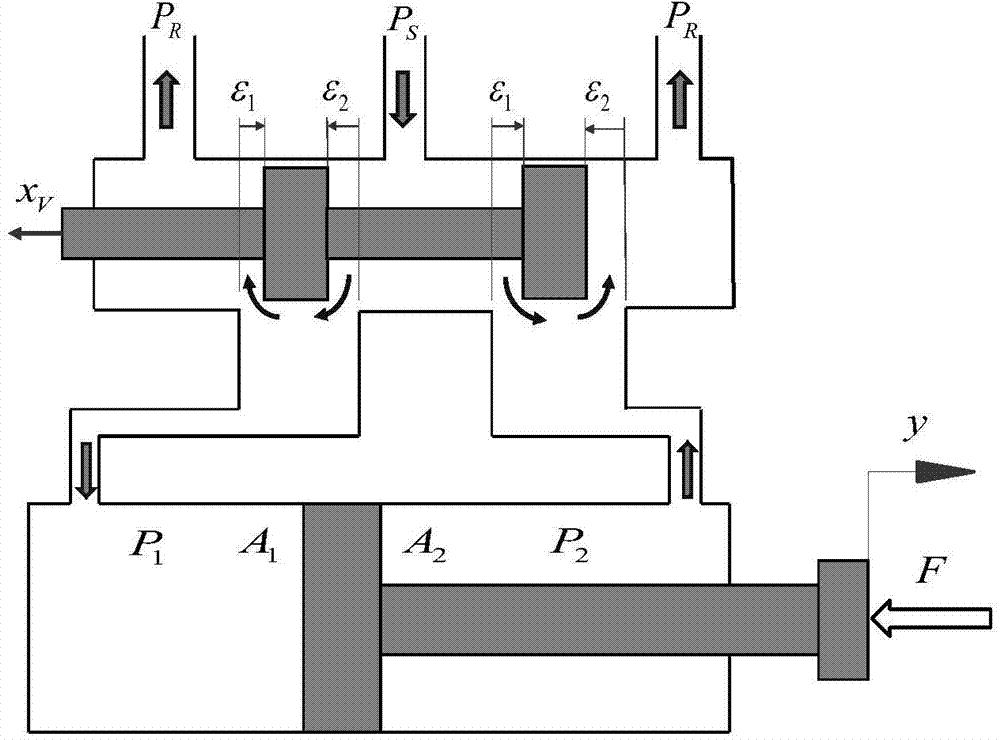

[0045] The internal structure diagram of the asymmetric electro-hydraulic proportional system, such as figure 2 shown.

[0046] The positive movement of the asymmetric cylinder in the y direction is the positive movement of the system, otherwise it is the reverse movement of the system; the ratio of the two chamber areas of the asymmetric cylinder is η=A 2 / A 1 , when η=1, it is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com