Process method for depositing and doping surface of silicon wafer

A process method and technology on the surface of silicon wafers, applied in the field of deposition and doping processes, can solve problems such as uneven concentration, uneven film thickness, and poor uniformity, and achieve increased doping concentration, uniform film thickness between sheets, and consistent reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take LPCVD doping as an example:

[0034] (1) Prepare 10 polished slices, 5 slices in group A grow a 100nm oxide layer, and 5 slices in group B are cleaned with hydrofluoric acid. (Group A is used to measure the film thickness of intrinsic silicon, group B is used to test the doping concentration, the same below)

[0035] (2) In the LPCVD furnace cavity, place a quartz boat, and put down a group A and a group B silicon wafer at 5 average intervals in the boat from the furnace mouth to the furnace tail (positions are respectively numbered 1, 2, 3, 4 , 5).

[0036] (3) Oxygen is introduced into the LPCVD furnace, and a layer of 1.5nm oxide layer is first grown on the surface of the silicon wafer.

[0037] (4) Evacuate oxygen and check for leaks.

[0038] (5) Control the temperature to 550°C and the pressure to 200mtorr, and start the aeration reaction;

[0039] The specific ventilation steps are:

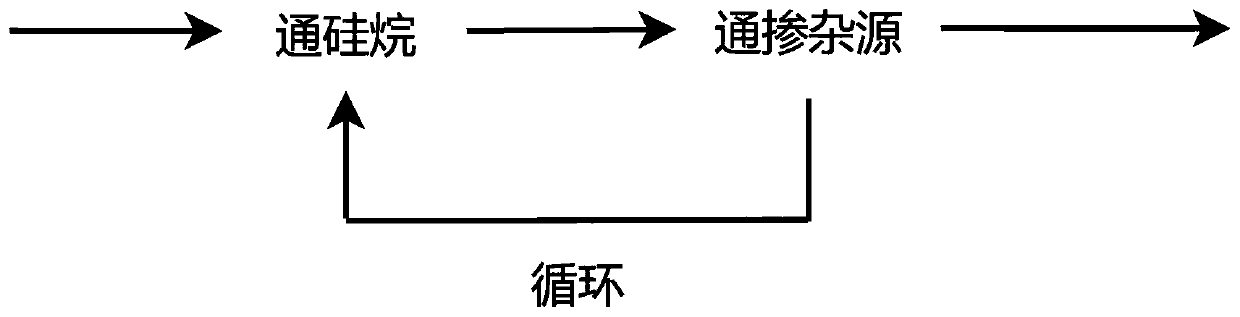

[0040] (5.1) Pass into 300sccm silane, the ventilation time is 60 sec...

Embodiment 2

[0050] Take LPCVD doping as an example:

[0051] (1) Prepare 10 polished slices, 5 slices in group A grow 100nm oxide layer, and 5 slices in group B are cleaned with hydrofluoric acid to remove the surface oxide layer.

[0052] (2) In the LPCVD boat, take 5 average intervals from the furnace mouth to the tail of the furnace and put down each silicon wafer of Group A and Group B (the positions are 1, 2, 3, 4, 5 respectively).

[0053] (3) Push the boat into the furnace tube, feed oxygen, and grow a 1.5nm thick oxide layer.

[0054] (4) Evacuate oxygen and check for leaks.

[0055] (5) Temperature control 570 degrees, pressure 450mtorr, start ventilation reaction;

[0056] The specific ventilation steps are:

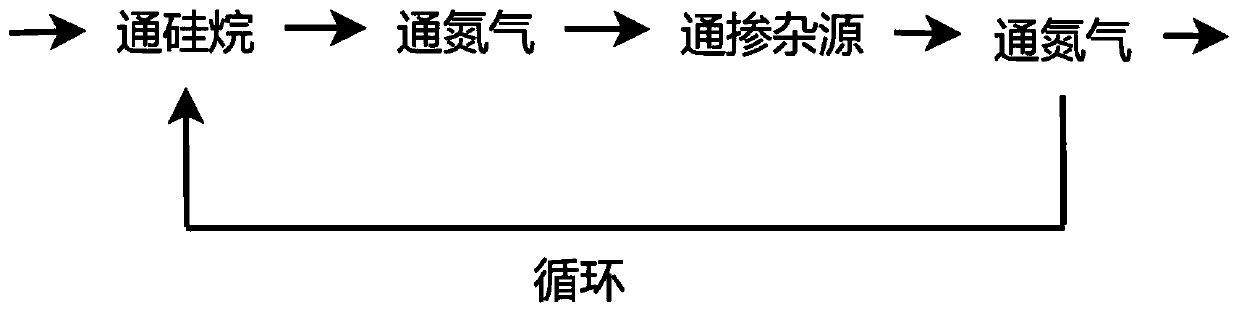

[0057] (5.1) Introduce a total flow rate of 380 sccm of silane, and ventilate for 60 seconds;

[0058] (5.2) Introduce 200 sccm of nitrogen, 300 sccm of phosphine total flow (diluted to volume concentration 3%), and ventilate for 4 seconds;

[0059] (5.3) Nitrogen gas...

Embodiment 3

[0069] Take LPCVD doping as an example:

[0070] (1) Prepare 10 polished slices, 5 slices in group A grow a 100nm oxide layer, and 5 slices in group B are cleaned with hydrofluoric acid.

[0071] (2) In the LPCVD furnace cavity, place a quartz boat, and place a silicon wafer of group A and group B at 5 average intervals in the boat from the furnace mouth to the tail of the furnace (positions are respectively numbered 1, 2, 3, 4 , 5).

[0072] (3) Propel the furnace tube, feed oxygen, and carry out the oxidation process at 530° C., and the oxidation time is 10 minutes.

[0073] (4) Evacuate oxygen and check for leaks.

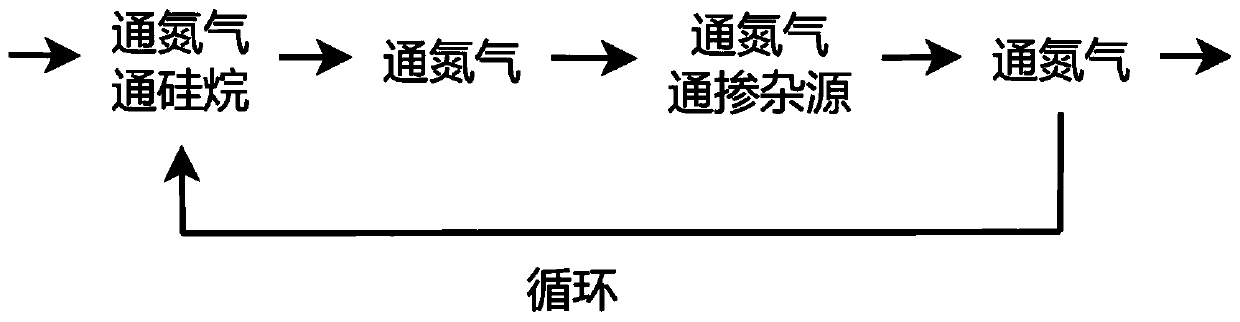

[0074] (5) The temperature is controlled at 580° C., the pressure is 500 mtorr, and the flow rate of nitrogen gas is maintained at 200 sccm, and nitrogen gas is still supplied at 200 sccm when the dopant source gas is supplied.

[0075] (6) silane, phosphine, silane, phosphine are circulated successively, (phosphine is diluted to a volume concentration of 3%)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com