Au@MoS2-based localized surface plasma enhanced NO2 gas sensor and preparation method thereof

A gas sensor and plasma technology, applied in the direction of nanotechnology, instruments, scientific instruments, etc. for sensing, can solve the problems of high sensitivity real-time detection obstacles of sensors, doubts about the accuracy of detection results, slow recovery speed of sensors, etc. Good anti-humidity interference ability, improving gas sensing performance, improving recovery rate and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

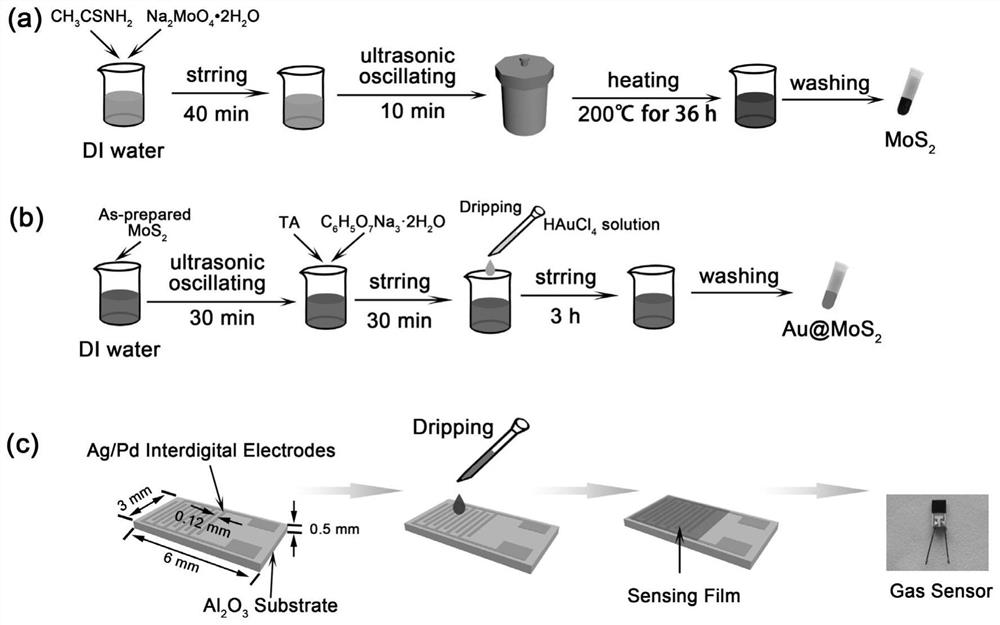

[0053] Au@MoS based Au@MoS according to embodiments of the present invention 2 The localized surface plasmon enhanced NO 2 The preparation method of the gas sensor includes the following steps:

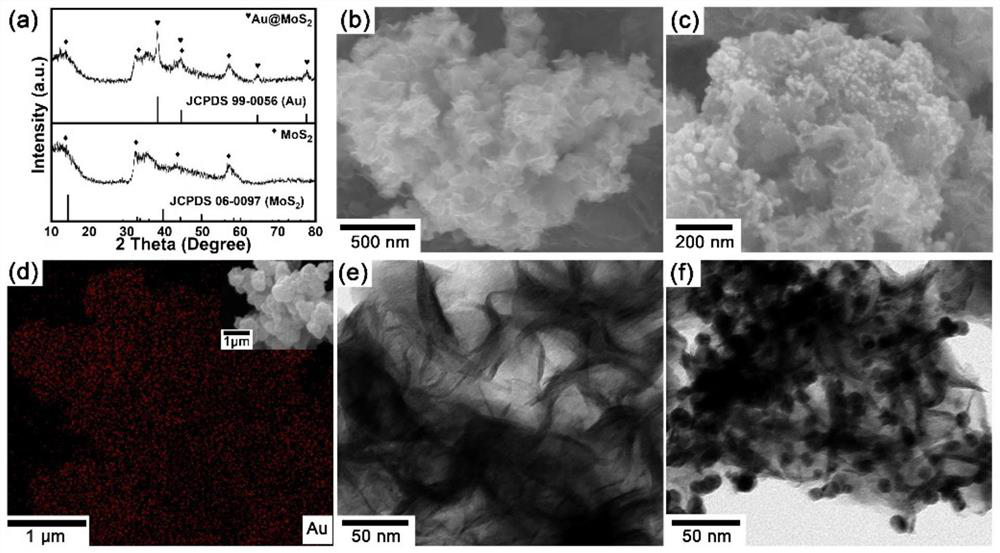

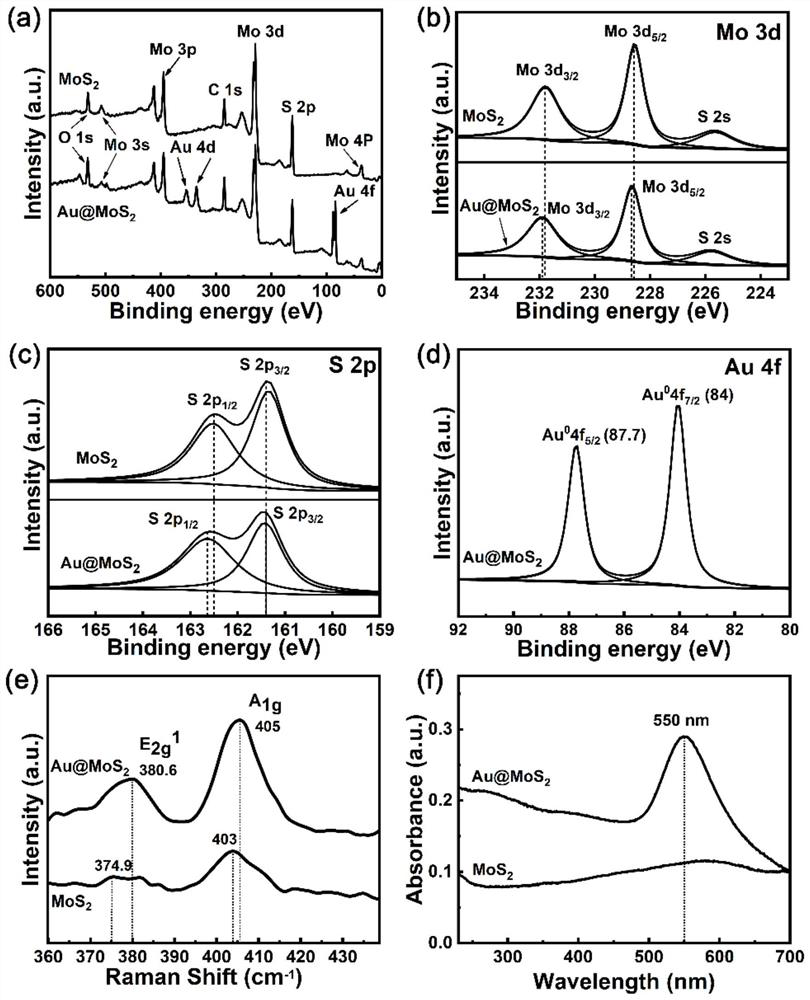

[0054] Preparation of MoS 2 Nanosheets, the MoS 2 The nanosheets have a hexagonal structure;

[0055] MoS with Au nanoparticles 2 Nanosheets are modified to obtain heterostructured Au@MoS 2 ;as well as

[0056] Au@MoS with heterostructure 2 Preparation of gas sensors as sensitive materials, specifically including: the heterostructure of Au@MoS 2 The powder was dispersed in an ethanol solvent to make a dispersion, and then in Al with multiple interdigitated electrodes 2 O 3 The dispersion liquid was drop-coated on the substrate, dried to form a sensitive film, and Au@MoS was prepared. 2 Gas sensors as sensitive materials;

[0057] Fixing the gas sensor in the first cavity of the detection box;

[0058] A light source is arranged in the second cavity of the detection box for...

Embodiment 1

[0081] MoS 2 Nanosheet preparation

[0082] Step 1-1, 0.97g sodium molybdate dihydrate (Na 2 MoO 4 ·2H 2 O) and 0.75 g of thioacetamide (CH 3 CSNH 2 ) dissolved in 80ml resistivity>18.4Ω / cm 2 ultrapure water;

[0083] Step 1-2, put the solution on a magnetic stirrer and stir for 40min at room temperature (25°C) to obtain a clear and transparent homogeneous solution;

[0084] Step 1-3, the obtained homogeneous solution is shaken for 10min in an ultrasonic oscillator with a power of 250W;

[0085] Step 1-4, transfer the solution to a 100ml polytetrafluoroethylene lined autoclave, put it into a vacuum drying oven and continue heating at 200°C for 36h;

[0086] Step 1-5, wait for the solution in the reactor to be cooled to room temperature (25°C) naturally;

[0087] Steps 1-6, use a centrifuge to collect MoS from the resulting mixed solution at a centrifugal speed of 7500 rad / min 2 Precipitate, wash with deionized water and absolute ethanol for 2 to 3 times by centrifuga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com