Frame-type die-casting product one-time punching device

A frame and product technology, which is applied in the field of one-time punching device for frame die-casting products, can solve problems such as multiple sets of molds, and achieve the effects of reducing process turnover, improving actual efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below with reference to the drawings.

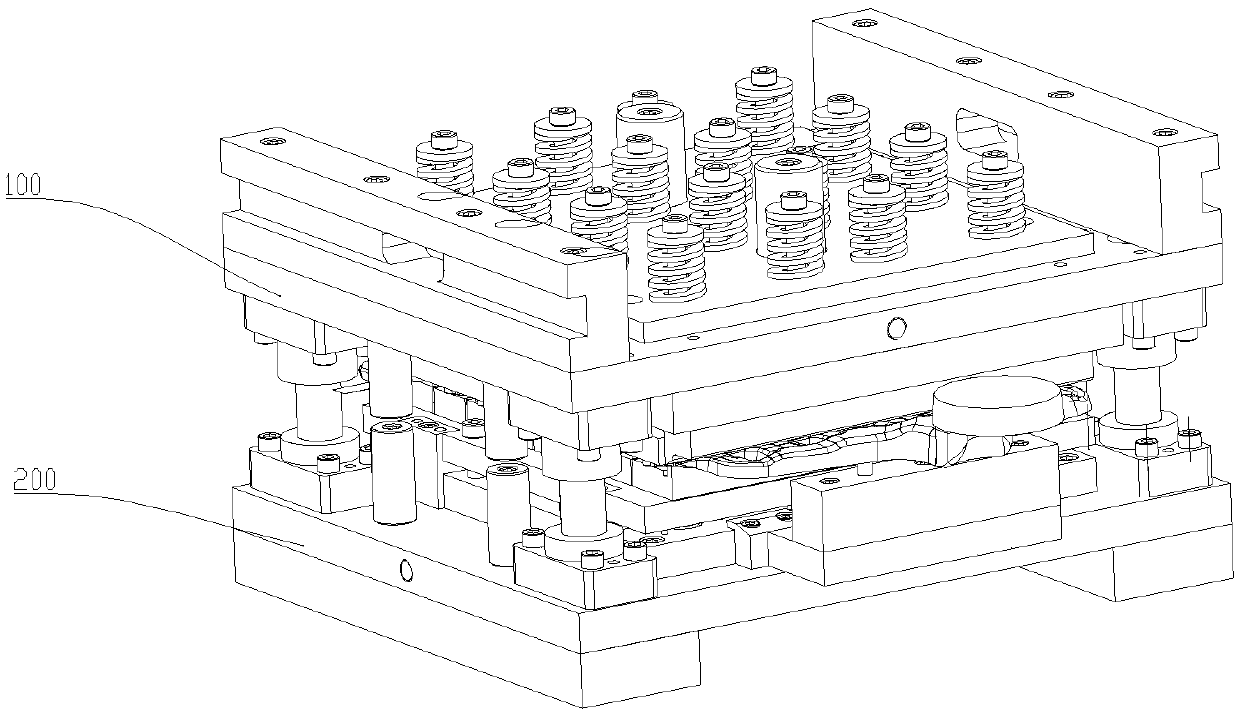

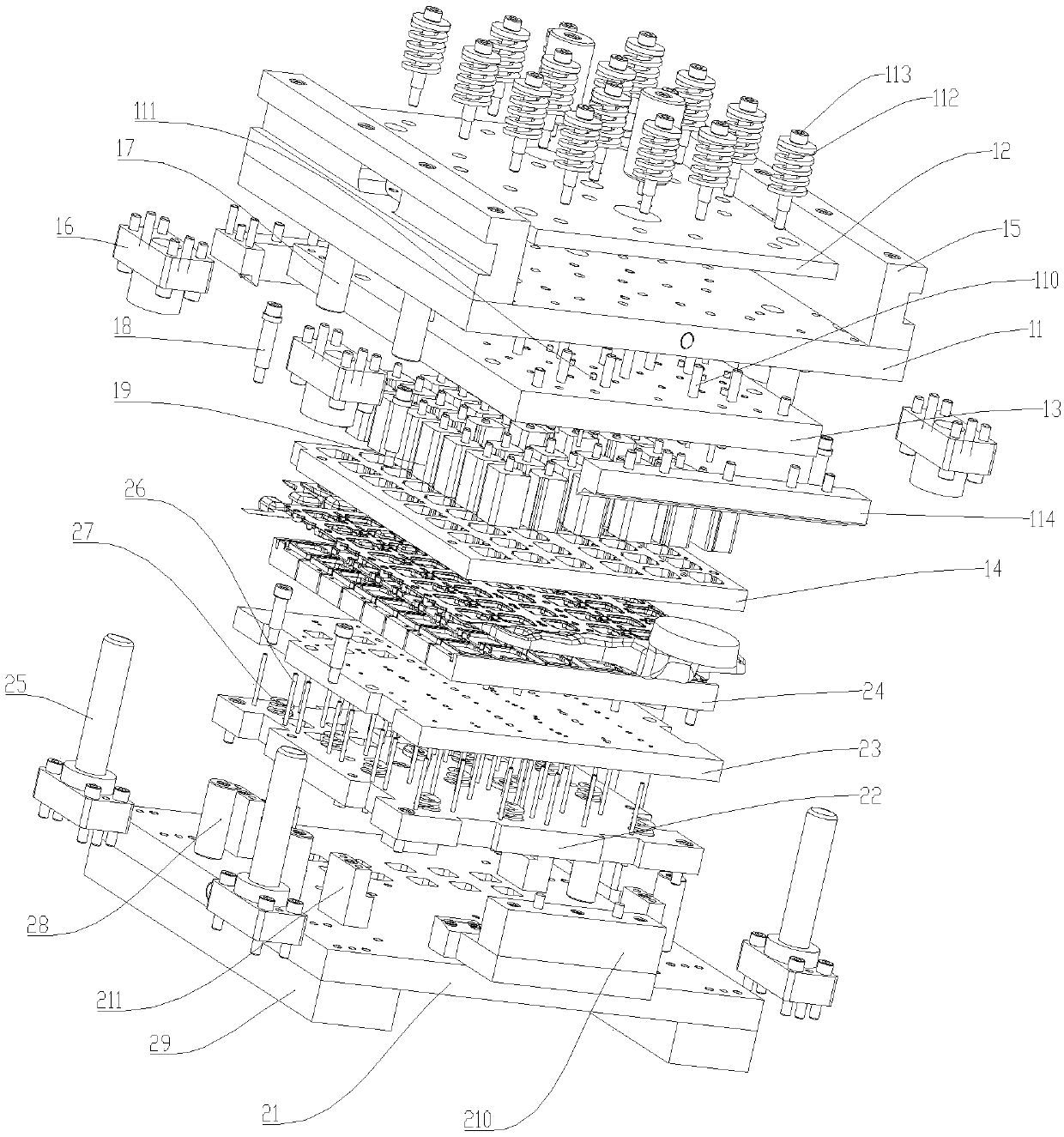

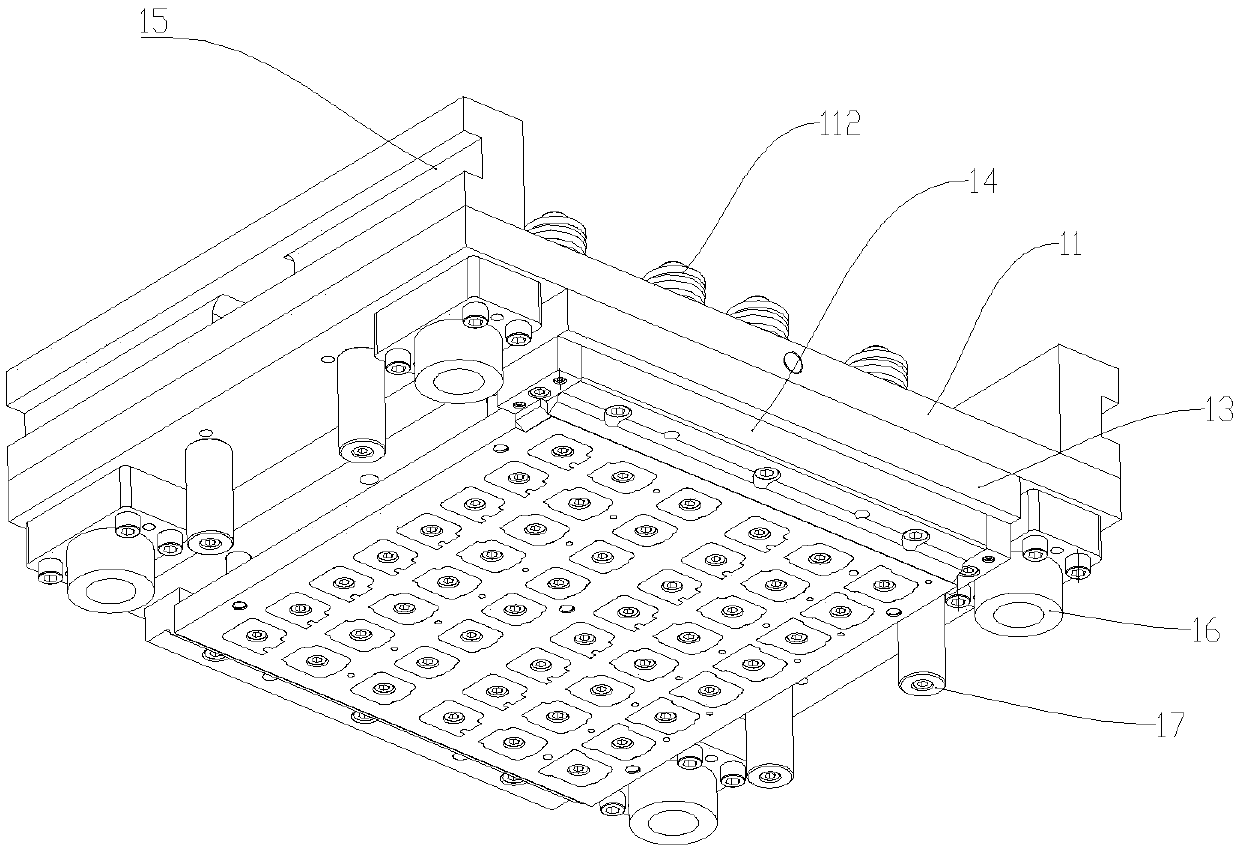

[0024] See Figure 1 to Figure 6 In this embodiment, the frame die-casting product one-time punching device includes: an upper mold assembly 100 and a lower mold assembly 200. The upper mold assembly 100 includes an upper template 11 connected to the upper mold assembly. The upper mold fixing plate 13 on the bottom surface of the template 11, and the upper mold stripper plate 14 hoisted on the upper mold fixing plate 13, and the upper mold fixing plate 13 is provided with a first punch 111 and a punch 19; The lower mold assembly 200 includes: a lower mold plate 21, a lower mold fixing plate 22 connected to the top surface of the lower mold plate 21, and a lower mold stripping plate 23 is provided on the lower mold fixing plate 22; The mold fixing plate 22 is provided with a second punching pin 26, and the top surface of the lower mold stripping plate 23 is also provided with positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com