Horizontal type broaching machine for automatic machining of plate roller plug

An automatic processing and plugging technology, which is applied in the direction of broaching machines, broaching devices, metal processing equipment, etc., can solve the problems of operation errors, high rigidity requirements of machine tool structures, and increased equipment costs, so as to achieve cost reduction and simple structure Reliable, the effect of solving operational errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

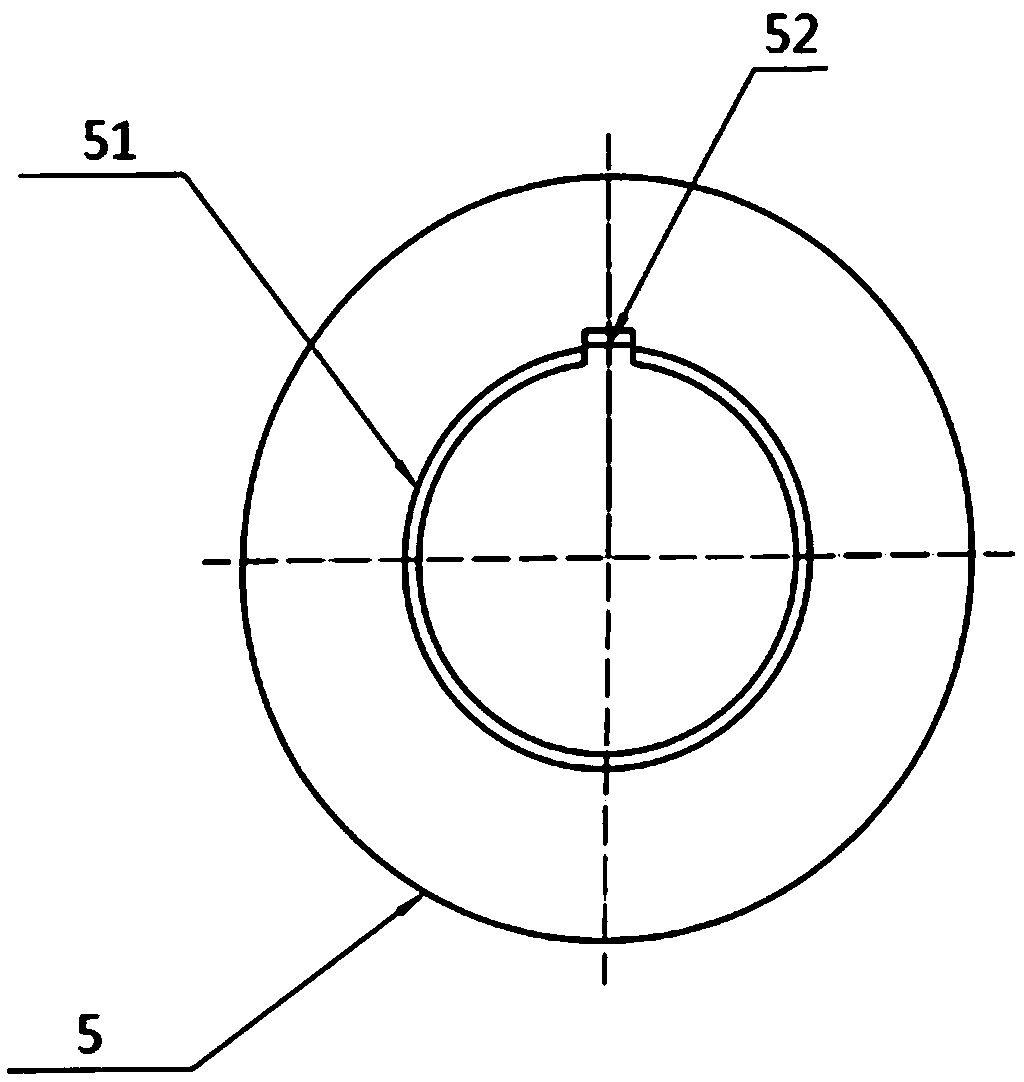

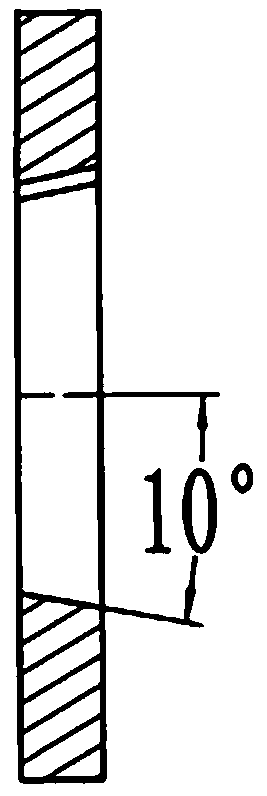

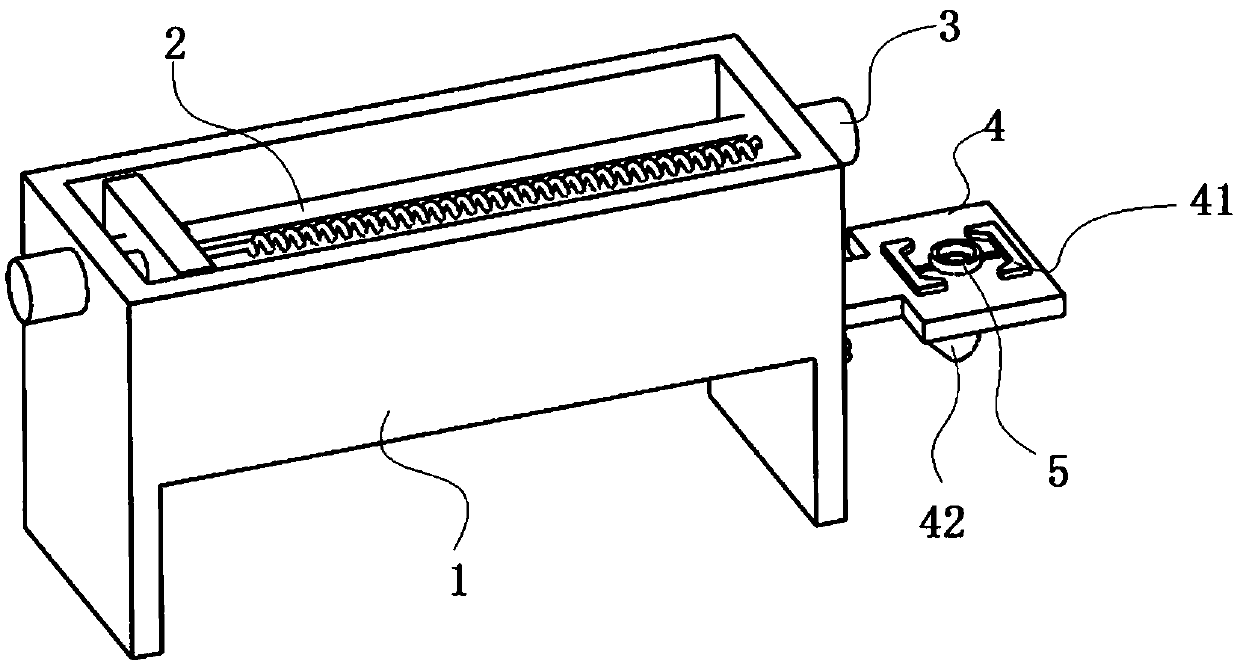

[0029] Such as Figure 3-5 A horizontal machine tool for the automatic processing of gravure roller plugs is shown, including a frame 1, a broach 2, a fixed fixture 3 and a turning table 4, the broach 2 is installed in the frame 1, and the fixed fixture 3 Installed on one side of the frame, the turning table 4 is installed on one side of the frame 1 and below the fixing fixture 3 . The overturning platform 4 also includes a self-centering fixture 41 and a turning cylinder 42 , the self-centering fixture 41 is installed above the turning platform 4 , and the turning cylinder 42 is installed under the turning platform 4 .

[0030] The specific usage method of this embodiment is as follows:

[0031] 1. The overturning table 4 is in a horizontal position, the self-centering fixture 41 is in a loose state, and the plug 5 to be processed is placed on the center of the self-centering fixture 41 on the overturning platform 4 by the manipulator;

[0032] 2. The self-centering fixture...

Embodiment 2

[0038] Such as Figure 6-7 As shown, Embodiment 2 is improved on the basis of Embodiment 1. The keyway processing requirements for plugs are different. Three broaches 2 of different specifications, three fixing fixtures 3 and three turning tables are installed on the frame 1. 4. The three broaches 2 move at the same time, and the three turning tables 4 operate according to the control signal, so as to solve the problem of manual replacement of the broaches and realize the automatic processing of plugs with various keyway specifications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com