Metal plate curved surface defect detecting tool

A defect detection and curved surface technology, applied in manufacturing tools, metal processing equipment, testing metals, etc., can solve problems such as difficult observation, deviation of test result data, and unfavorable curved surface defect detection work, so as to eliminate the need for cleaning burrs and speed up work. effect of progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

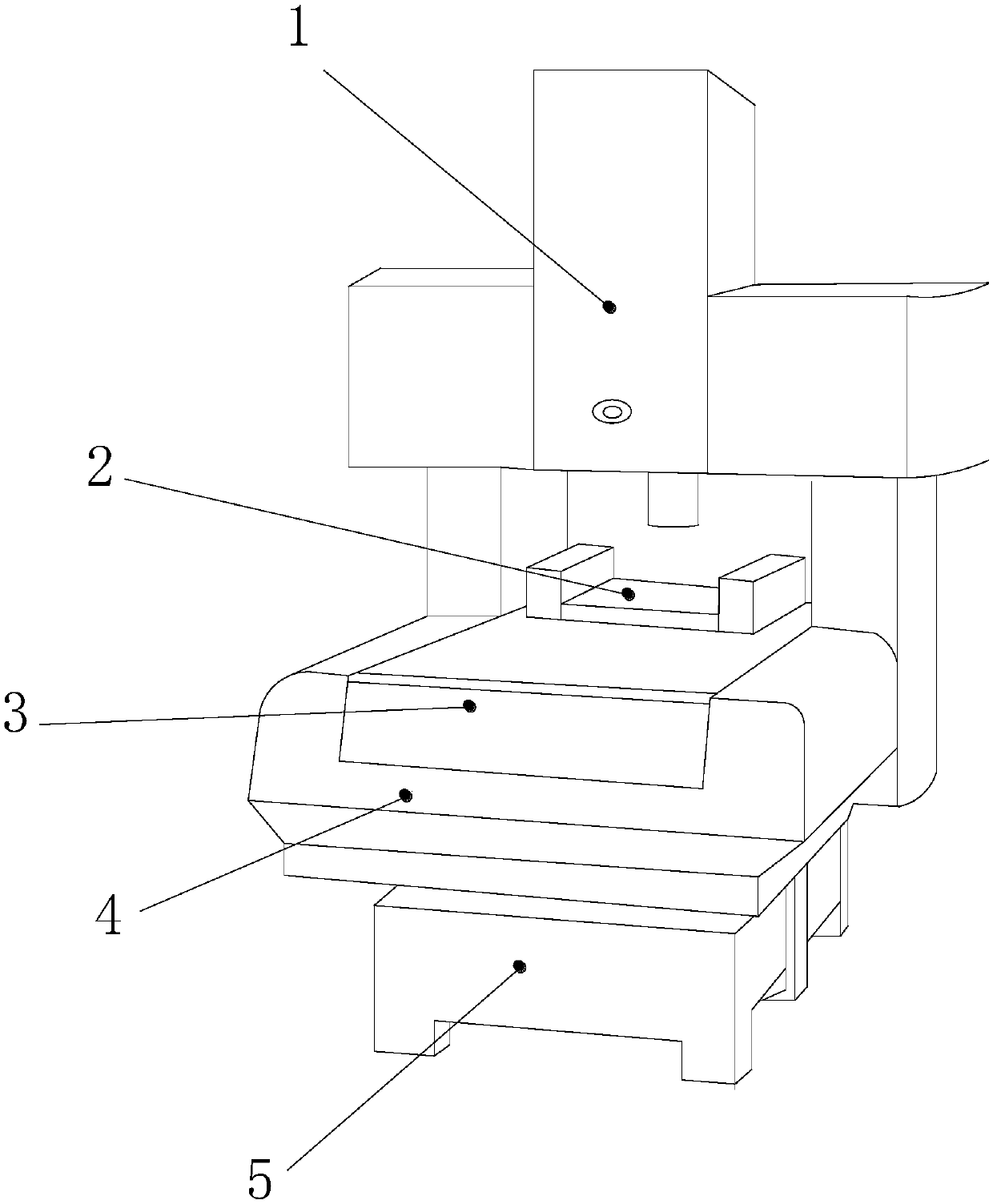

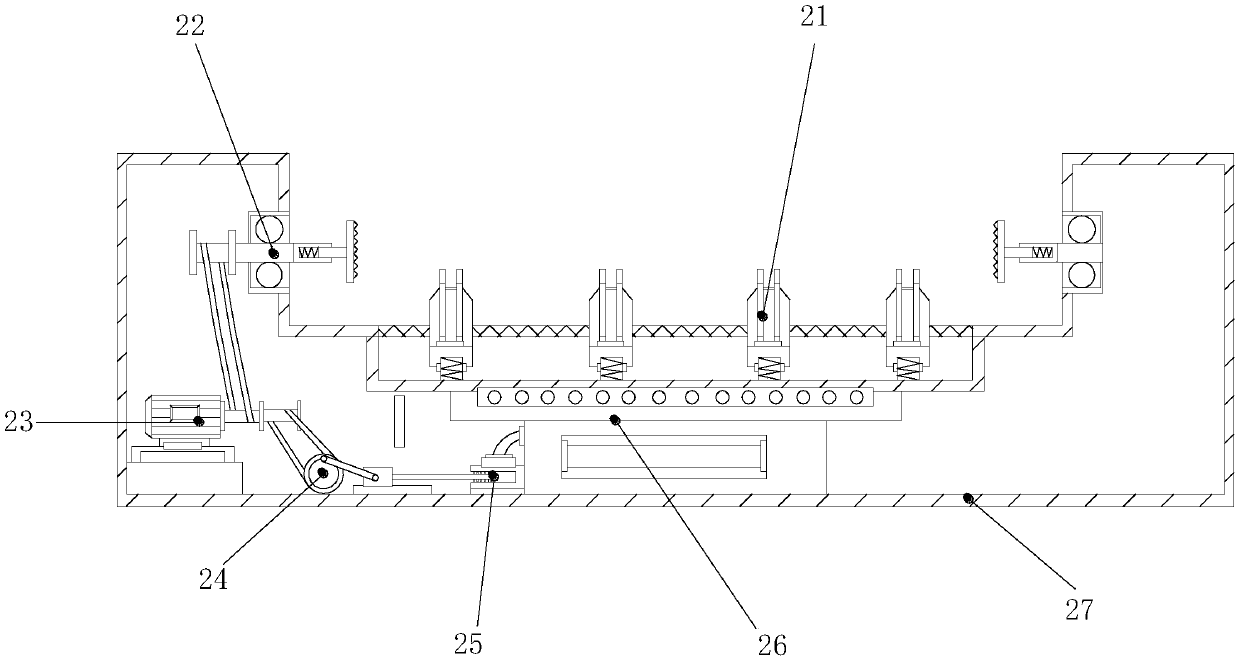

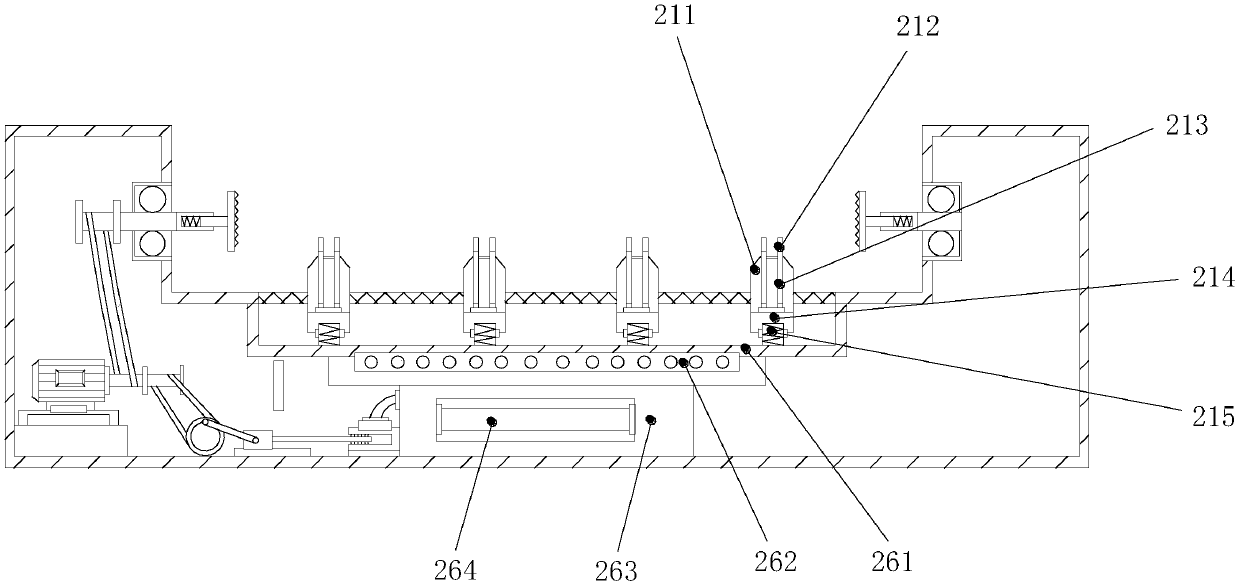

[0024] see Figure 1-Figure 6, the present invention provides a sheet metal curved surface defect detection tool, the structure of which includes a detector 1, a clamping disc 2, a workbench 3, a body 4, and a base 5, the detector 1 is located directly above the clamping disc 2, and the The bottom end of the clamping disc 2 is welded to the top end of the workbench 3, the workbench 3 is arranged on the body 4, and the two are an integrated structure, the bottom end of the body 4 is welded to the top end of the base 5 , the clamping disc 2 includes a deburring mechanism 21, a clamping assembly 22, a driving mechanism 23, a driven mechanism 24, a power generating mechanism 25, a power connection assembly 26, and a housing 27, and the deburring mechanism 21 is vertically embedded in the housing 27 The top of the middle part, and the two are welded, the bottom of the burr removal mechanism 21 is welded with the top of the power connection assembly 26, the driving mechanism 23 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com