Pressure transmitter applied to trolley

A transmitter and pressure technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve the problems of affecting the service life, not having the liquid to be tested, and the measurement accuracy of the pressure transmitter is not high, to achieve Effects of improving reliability and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

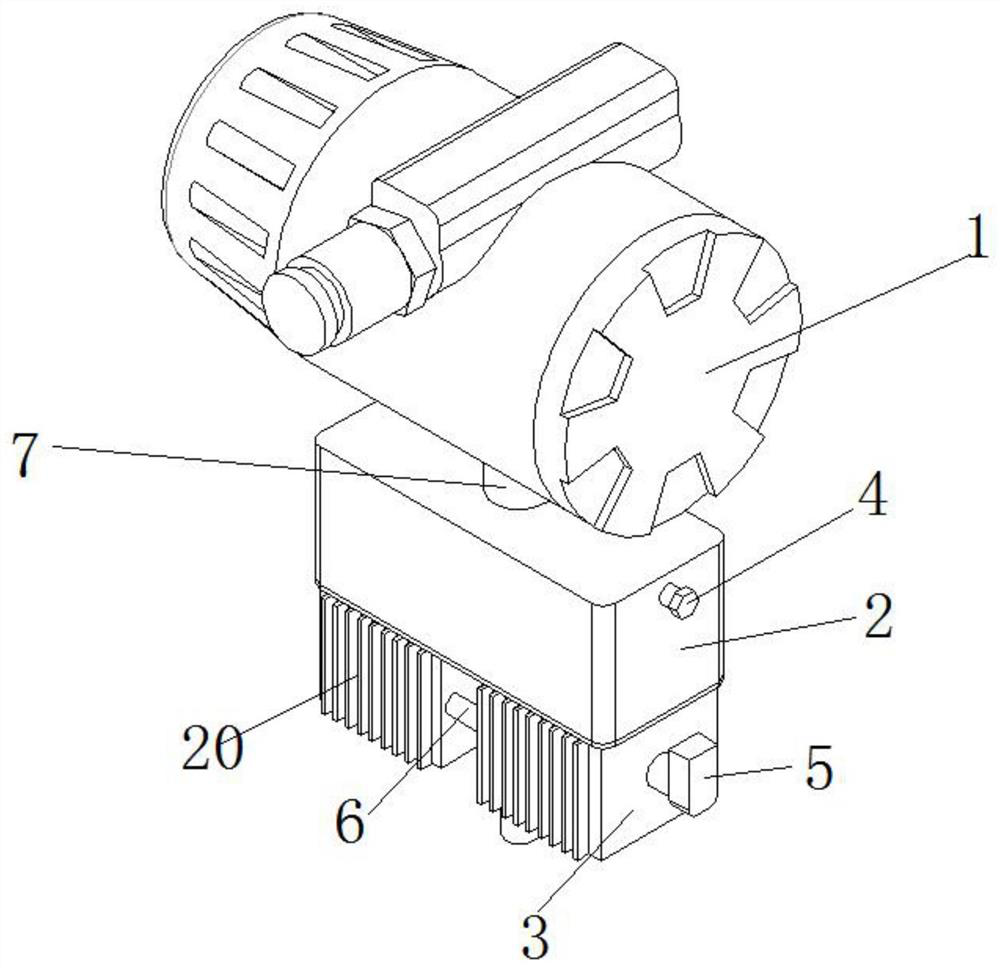

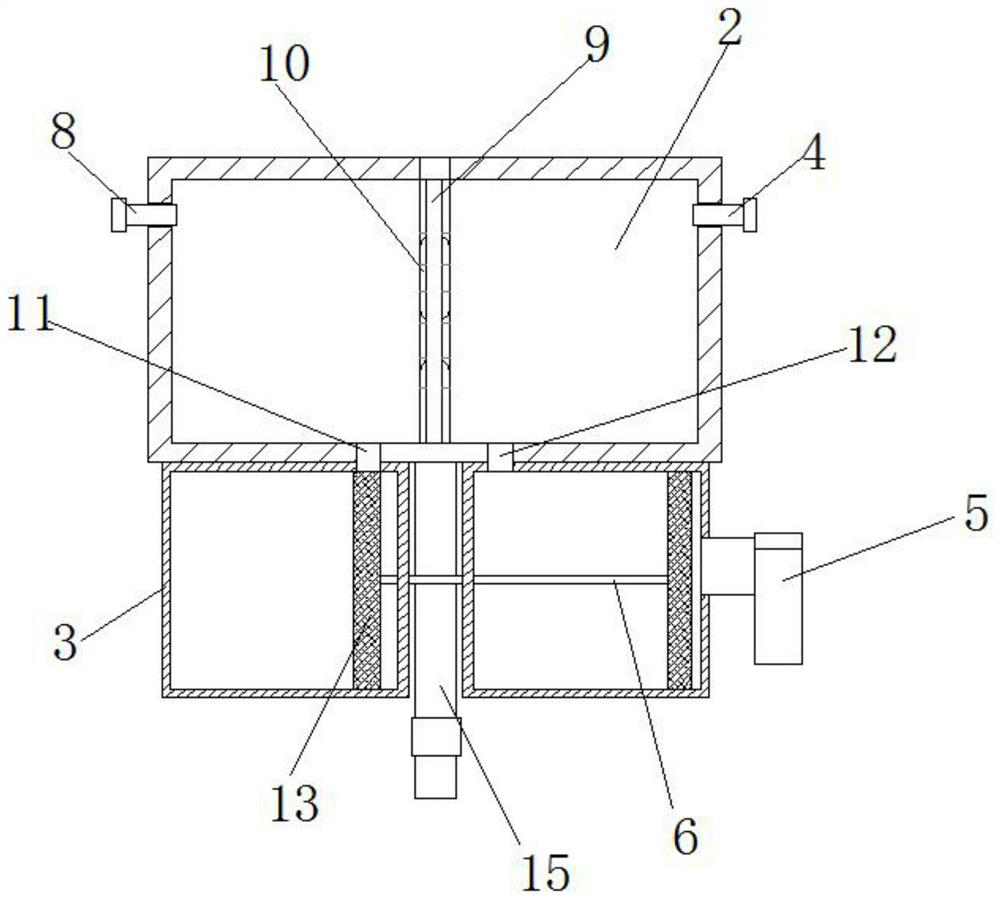

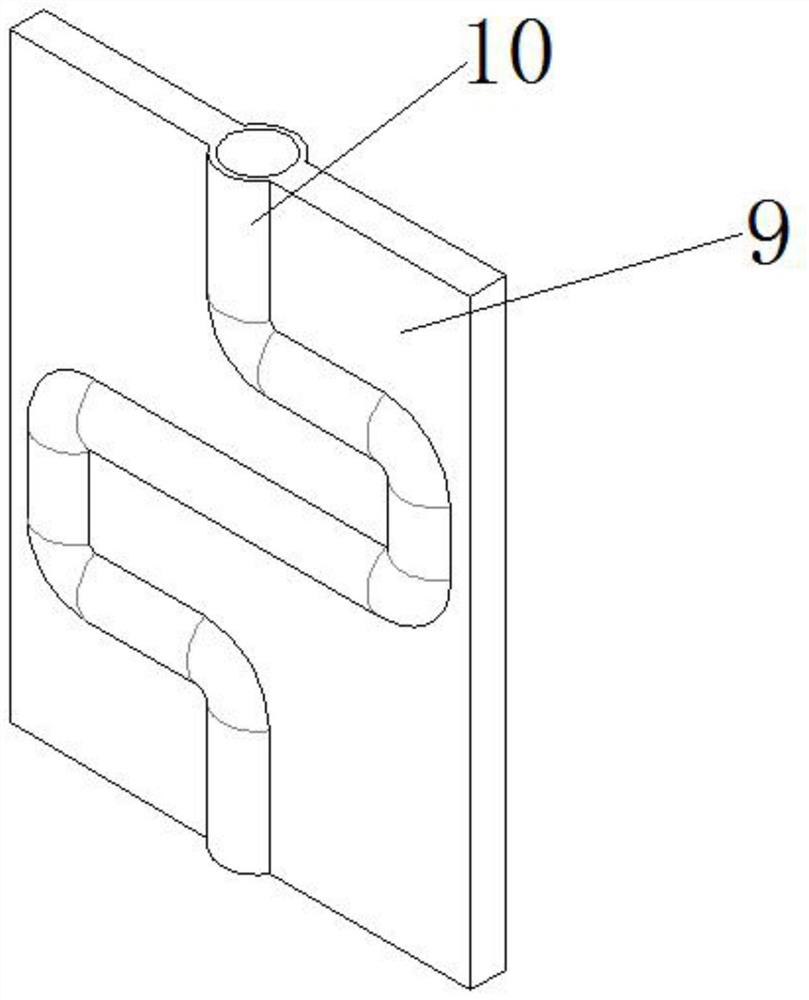

[0024] refer to Figure 1-4 , the pressure transmitter applied to the trolley, including the transmitter body 1, the liquid inlet 7 is vertically inserted and fixed at the middle position of the lower part of the transmitter body 1, and the liquid inlet 7 is horizontally provided with a cooling chamber 2 for cooling A bent pipe 10 is installed vertically at the middle position inside the warehouse 2, and the lower end of the liquid inlet 7 passes through the inner top wall of the cooling chamber 2 and communicates with the upper end of the bent pipe 10, and a partition plate 9 is vertically welded at the middle position inside the cooling chamber 2 , the bent pipe 10 is sealed and welded in the partition 9 and both sides are exposed, the partition 9 divides the interior of the cooling chamber 2 into two cavities, and a first connecting pipe 15 is vertically inserted in the middle of the lower part of the cooling chamber 2, and The upper end of the first connecting pipe 15 pass...

Embodiment 2

[0028] refer to figure 1 with 3-5, the pressure transmitter applied to the trolley, including the transmitter body 1, the liquid inlet 7 is vertically inserted and fixed at the middle position of the lower part of the transmitter body 1, and the liquid inlet 7 is horizontally equipped with a cooling chamber 2 The middle position inside the cooling chamber 2 is vertically provided with a bent pipe 10, and the lower end of the liquid inlet 7 passes through the inner top wall of the cooling chamber 2 to communicate with the upper end of the bent pipe 10, and the middle position in the cooling chamber 2 is vertically welded with a partition The plate 9 and the bent pipe 10 are sealed and welded in the partition 9 and exposed on both sides. The partition 9 divides the interior of the cooling chamber 2 into two cavities, and a first connecting pipe 15 is vertically inserted in the middle of the lower part of the cooling chamber 2. , and the upper end of the first connecting pipe 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com