Automobile part detecting fixture device

A technology for detecting fixtures and auto parts, applied in manufacturing tools, workbenches, etc., can solve the problems of gaps between fixtures and auto parts, cannot be detected, and form blind spots.

Inactive Publication Date: 2019-04-12

象山维治模具有限公司

View PDF6 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Although the above-mentioned technical solution solves the problem that the clamp cannot adapt to auto parts of different specifications as a whole, the clamp clamps the auto parts placed on the support table by adjusting the height and distance of the expander. After clamping the auto parts, only It can detect the upper surface and two sides of the auto parts, and the part where the fixture is in contact with the auto parts will form a blind area and cannot be detected, resulting in detection errors; and some auto parts have irregular shapes on the surface, and The clamping surface of the fixture is flat and cannot adapt to the clamping degree of the surface of the auto parts in contact with it, so that a gap will be formed between the fixture and the surface of the auto parts, resulting in loose or unstable clamping, which increases the detection accuracy. error

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0032] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

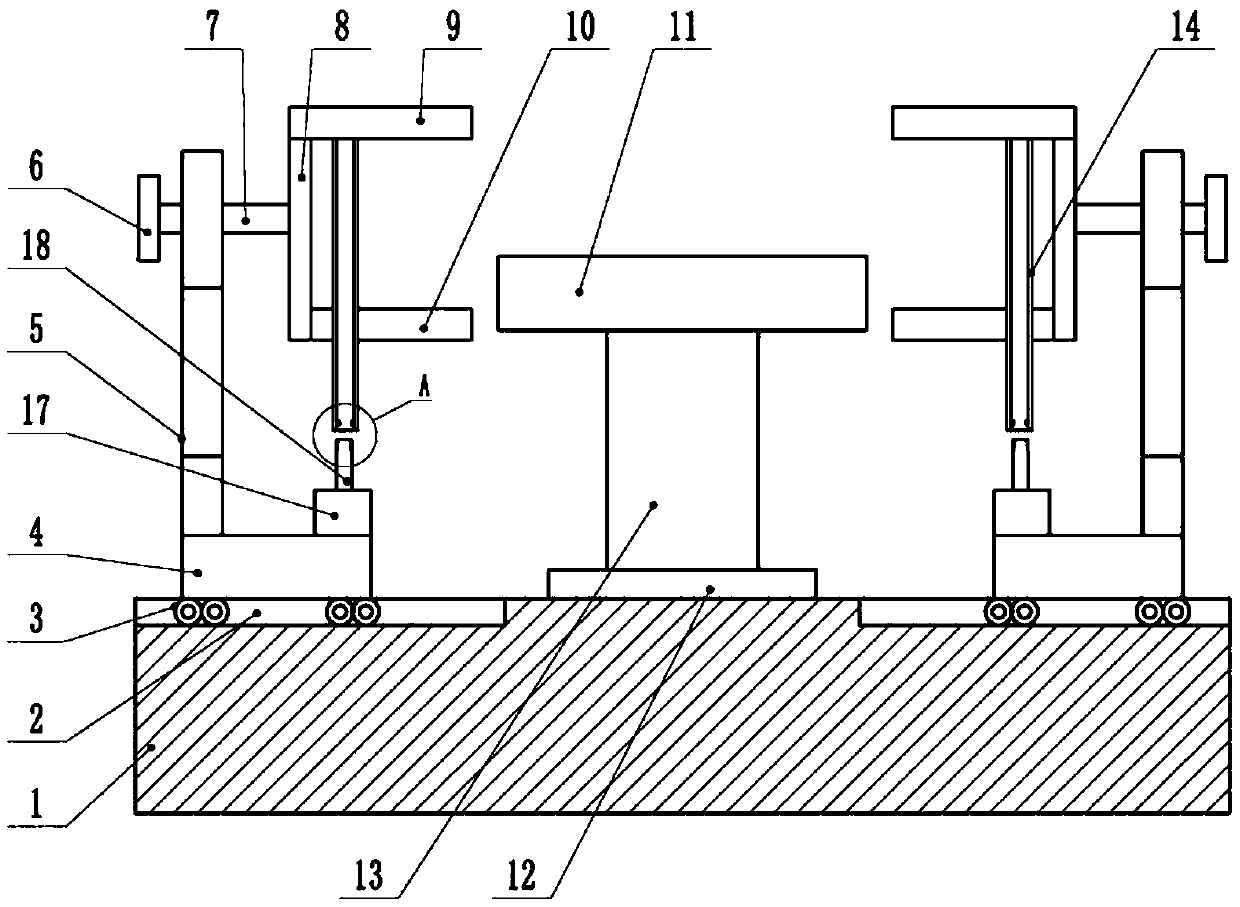

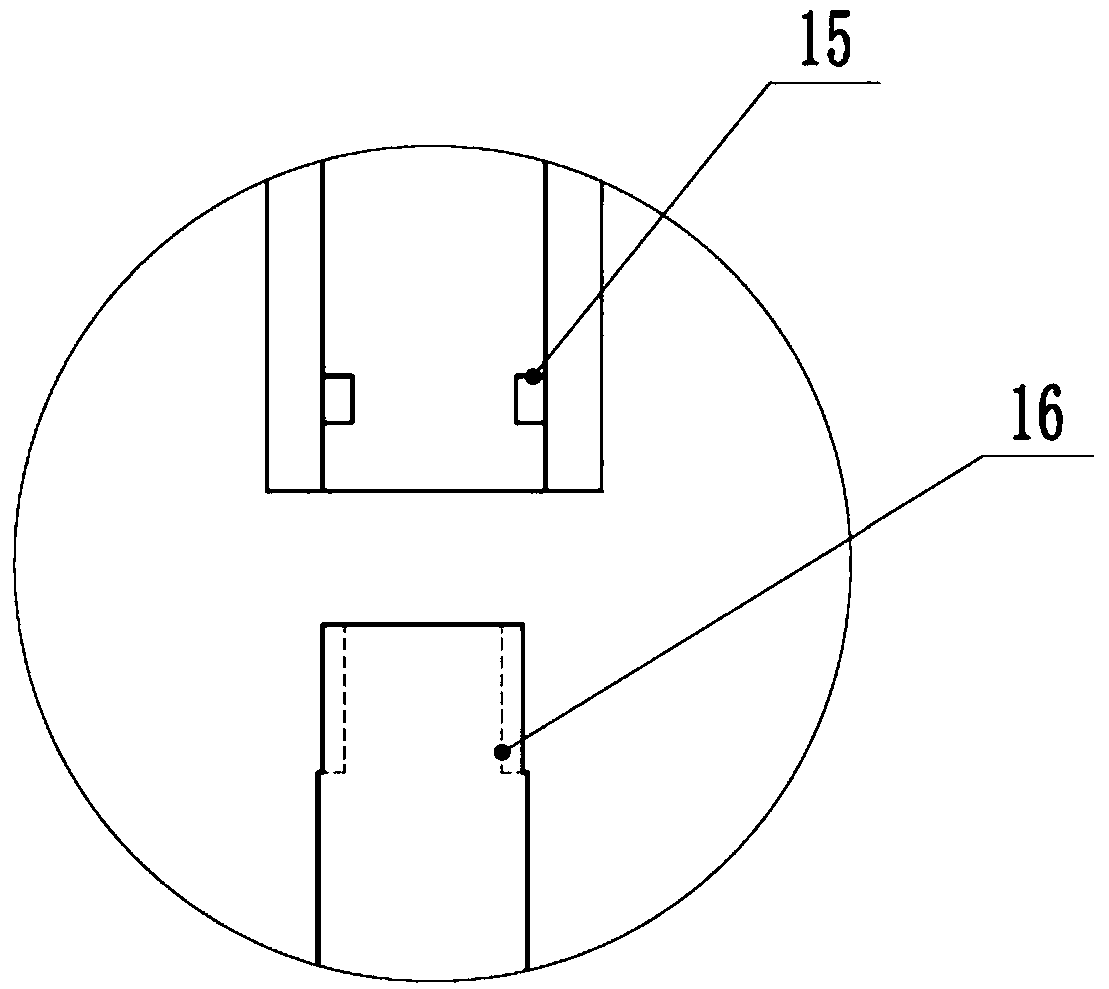

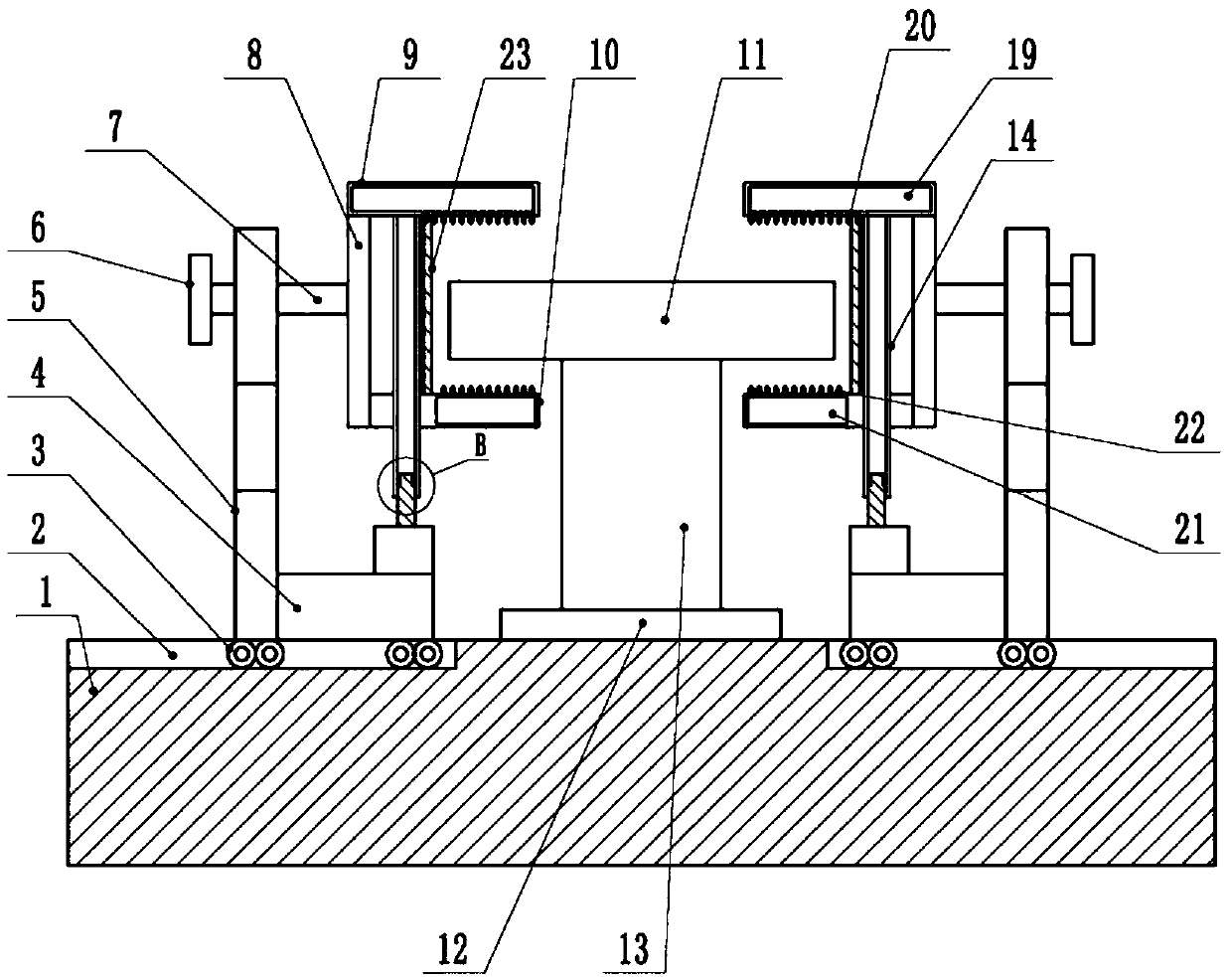

The invention belongs to the technical field of mechanical fixtures, and particularly relates to an automobile part detecting fixture device. The automobile part detecting fixture device comprises a working platform, a supporting pillar which is perpendicular to the working platform is arranged on the upper surface of the middle part of the working platform, and a rotary platform is arranged between the supporting pillar and the working platform; guiding rails are formed in the upper surface of the working platform, rolling wheel sets are arranged on the guiding rail, moving platforms are connected to the rolling wheel sets, telescopic rods which are perpendicular to the moving platforms are connected to the upper surfaces of the moving platforms, and clamping mechanisms are connected to the telescopic rods; and rotary discs are connected to the clamping mechanisms, threaded rods are rotatably connected to the clamping mechanisms, motors are arranged on the lower parts of the threadedrods, output shafts of the motors face the threaded rod directly, internal holes are formed in the lower parts of the threaded rods, and the output shaft of the motors are connected with the side walls of the internal holes in a key mode. The automobile part detecting fixture device is used for clamping automobile parts when the automobile parts are detected, can be suitable for the automobile parts of different size specifications, and can improve the clamping tightness to improve the detecting precision.

Description

technical field [0001] The invention belongs to the technical field of mechanical fixtures, in particular to a testing fixture device for auto parts. Background technique [0002] Auto parts are the various units that make up the whole car and a product that serves the car. With the improvement of people's living standards, people's overall requirements for cars are getting higher and higher, and auto parts play a very important role in the whole car. Therefore, the requirements for auto parts are getting higher and higher. Often, good-quality auto parts will bring a different experience to the car, and even good-quality auto parts are related to the safety of the car and the experience of the user. . [0003] The quality of auto parts is not only judged by people's subjective feelings, but also requires special testing instruments to detect auto parts to judge whether the parts meet the corresponding standard specifications. Therefore, after the auto parts are manufacture...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B25H1/10

CPCB25H1/10

Inventor 毛薇薇

Owner 象山维治模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com