Full-automatic insert injection molding machine

An injection molding machine, fully automatic technology, applied in the direction of coating, can solve the problems of applicability and practicability, affecting the efficiency of processing, increasing costs, etc., to achieve the effect of saving labor costs, improving efficiency, and stable and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

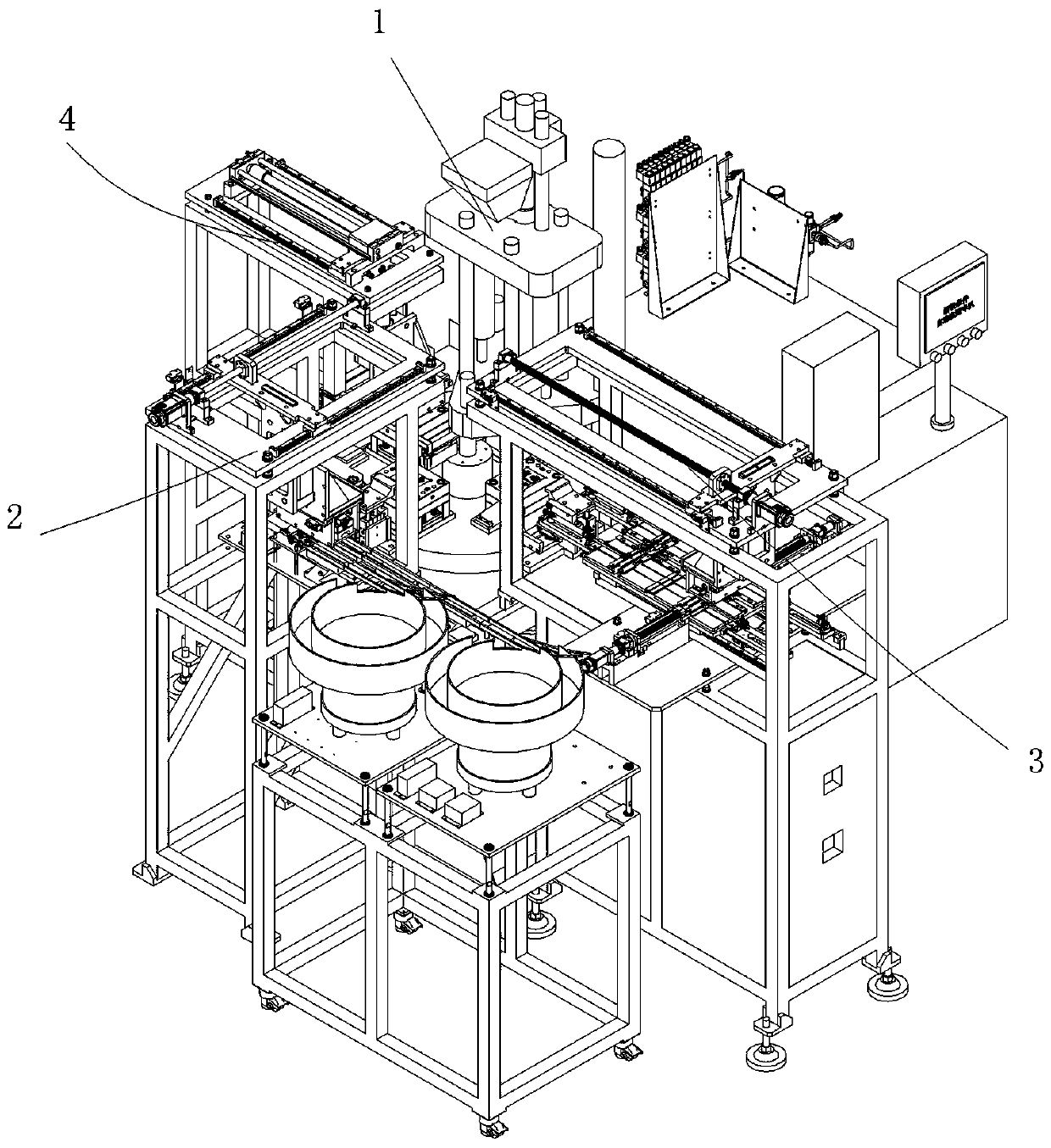

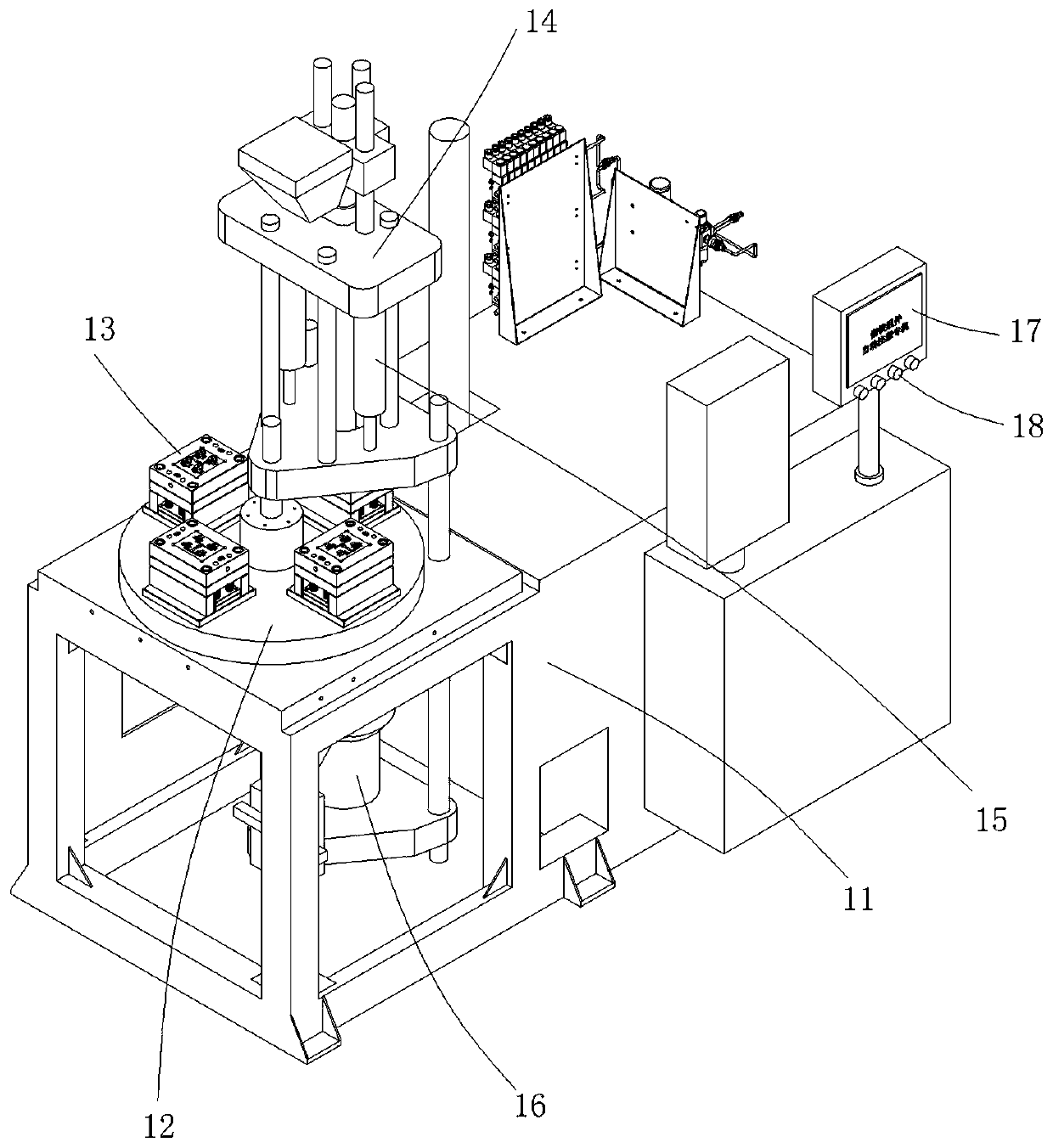

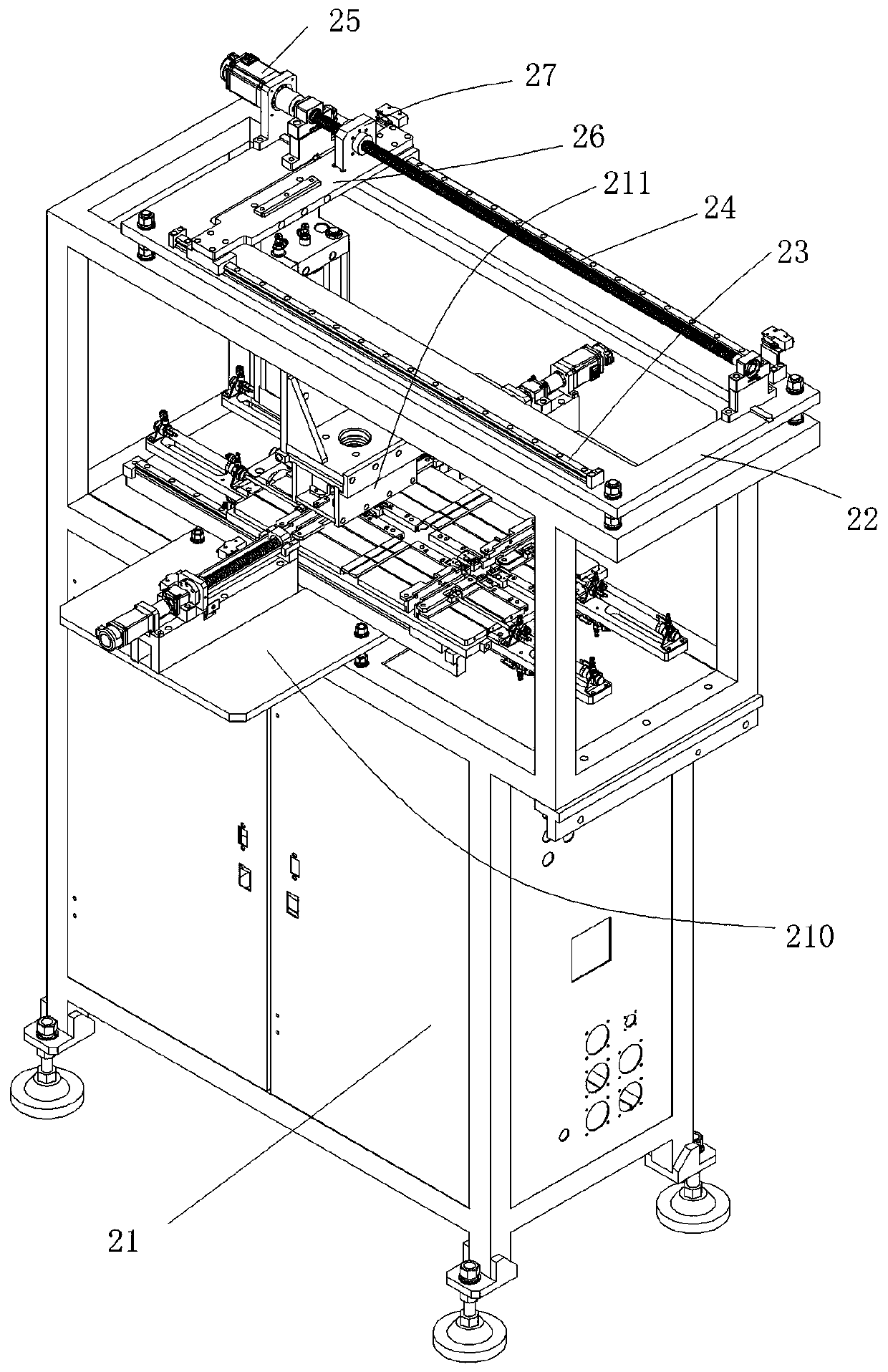

[0023] Figure 1 to Figure 9 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a structural schematic diagram of a vertical multi-station injection molding machine of the present invention; image 3 It is a structural schematic diagram of the magnetic steel automatic pick-and-place device in the present invention; Figure 4 for image 3 Schematic diagram of the structure of the magnetic steel distribution module; Figure 5 for image 3 Schematic diagram of the middle slide rail Figure 6 It is a structural schematic diagram of the steel sheet automatic pick-and-place device in the present invention; Figure 7 for Figure 6 Schematic diagram of the structure of the straight-line feedway; Figure 8 for Figure 6 Schematic diagram of the structure of the clamping track; Figure 9 It is a structural schematic diagram of the finished product and waste material taking-out device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com