Marine refrigerator body with welded aluminum honeycomb totally enclosed concave tray

An aluminum honeycomb, fully enclosed technology, used in household refrigeration devices, applications, coolers, etc., can solve the problems of water leakage and heavy weight at the bottom of marine cold storage, and achieve the effect of ensuring thermal insulation performance, saving maintenance costs, and solving bottom gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

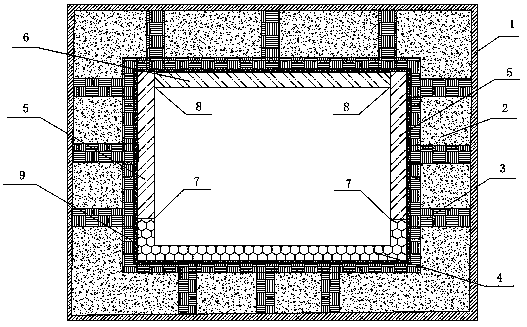

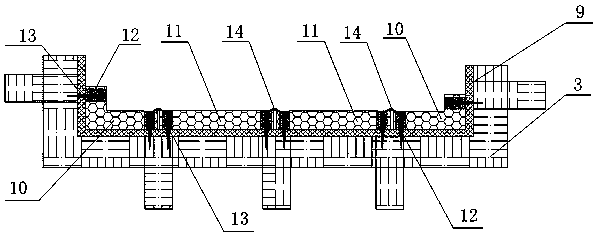

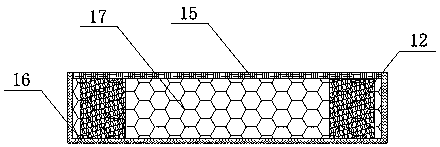

[0027] Such as figure 1 As shown, a marine cold storage body with a welded aluminum honeycomb fully enclosed concave tray, including: a frame 3, a galvanized steel plate 1 wrapped outside the frame 3, an insulation layer 2 filled between the frames 3, and an inner bottom of the frame 3. Welded aluminum honeycomb fully enclosed concave tray 4, wall panels 5 arranged around the inner side of the frame 3, and ceiling 6 arranged on the inner top of the frame 3. The seam between the welded aluminum honeycomb fully enclosed concave tray 4 and the wall panel 5 is welded by argon arc welding or connected with a bead to form a seam 7 between the welded aluminum honeycomb concave tray and the wall panel. The seam between the wallboard 5 and the ceiling 6 is welded by argon arc welding or connected with a bead to form a seam 8 between the wallboard and the ceiling. Preferably, the wall panels 5 are welded aluminum honeycomb panels, which can also be combined with flame-retardant plywood...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com