Intelligent roller structure of belt conveyor

A belt conveyor, intelligent technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of lack of maintenance, tearing, and the service life does not reach the design life, and improve the The effect of management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

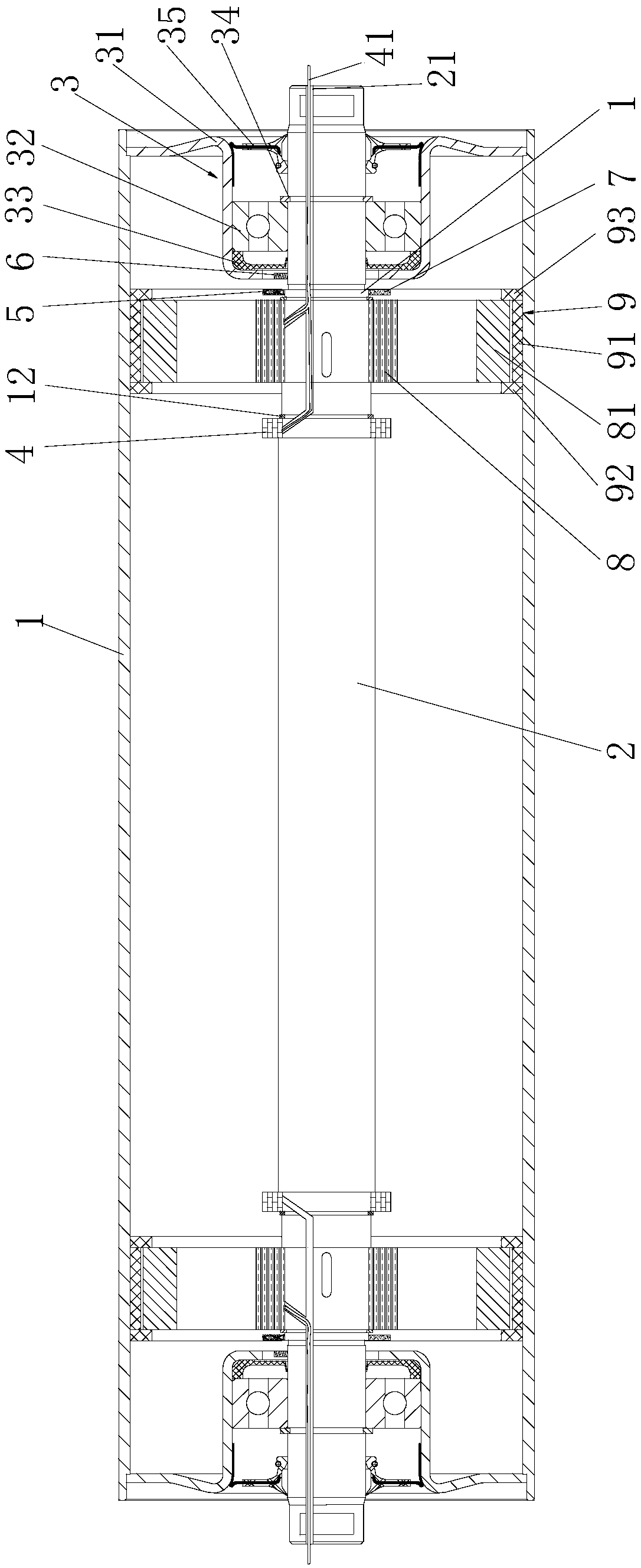

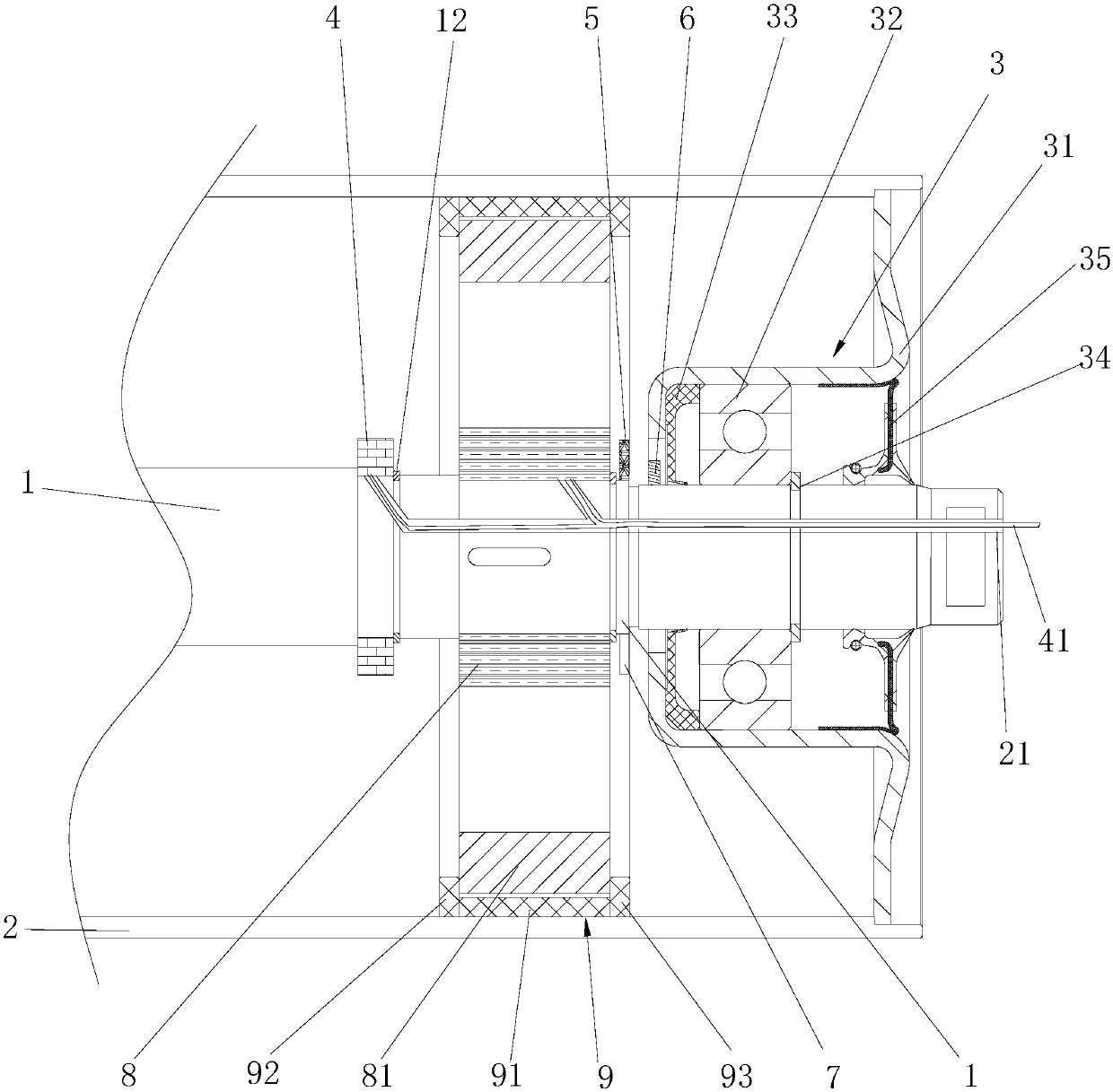

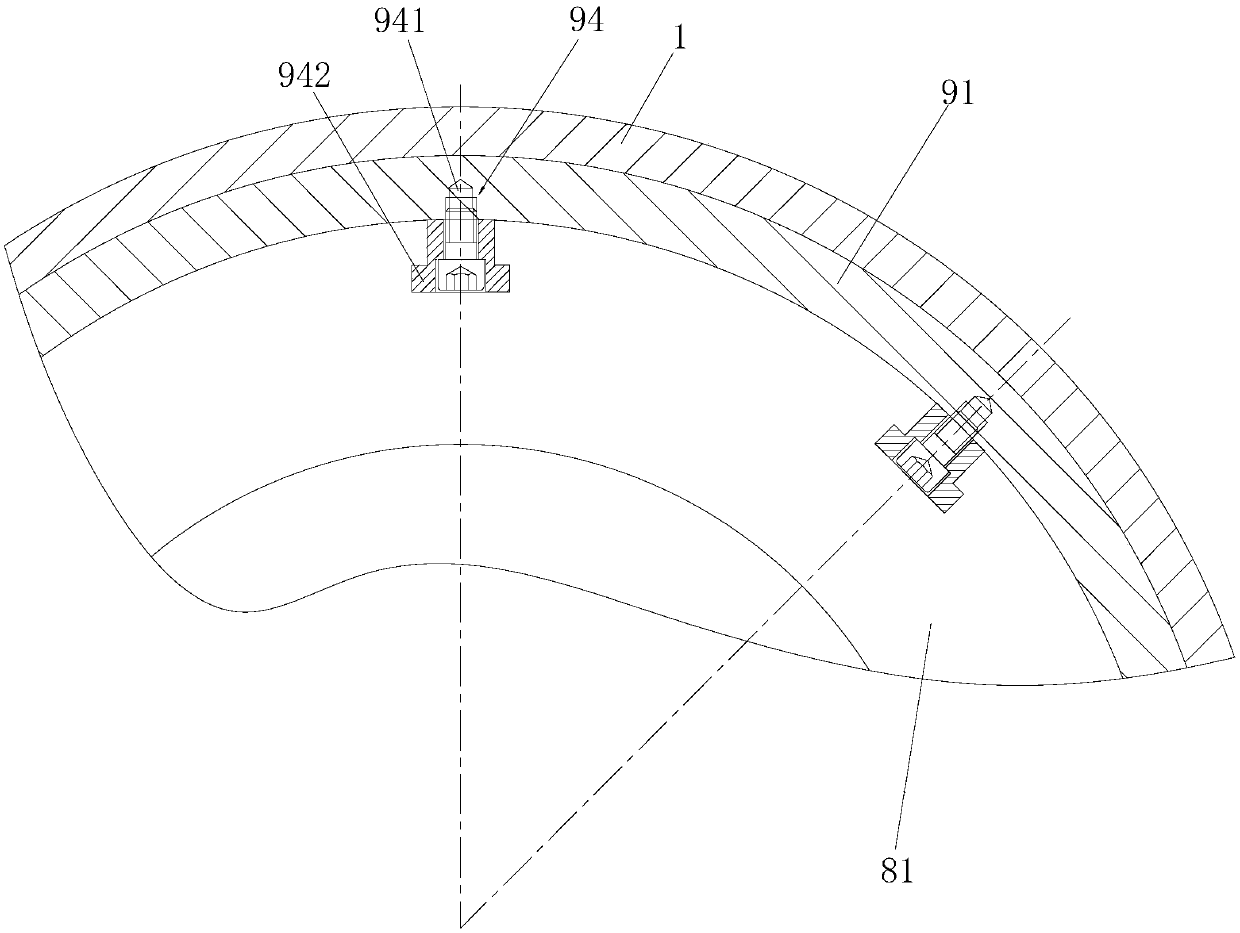

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

[0027] combine Figure 1 to Figure 3 , an intelligent belt conveyor idler structure, including an idler shell 1, an idler shaft 2 and a detection mechanism, the idler shaft 2 passes through the idler shell 1 and passes through two first bearing assemblies 3 and the idler shell 1 connected. Two first bearing assemblies 3 are respectively arranged in both ends of the idler shell 1 , and a set of detection mechanisms are arranged inside each first bearing assembly 3 .

[0028] The first bearing assembly 3 includes a first bearing seat 31 , and the first bearing seat 31 is sleeved on the roller shaft 2 . The detection mechanism includes a circuit board 4 , a vibration sensor 5 , a temperature sensor 6 and a microphone 7 . The temperature sensor 6 is connected to the outer wall of the first bearing seat 31 and connected to the outer wall of the idler shaft 2 .

[0029] The idler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com