Experimental device and measurement method for cutting heat and drilling parameters of rotary drilling in ice layer

A technology of drilling parameters and experimental devices, applied in the field of drilling, can solve the problem that the thermal influence of cutting cannot be accurately obtained, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

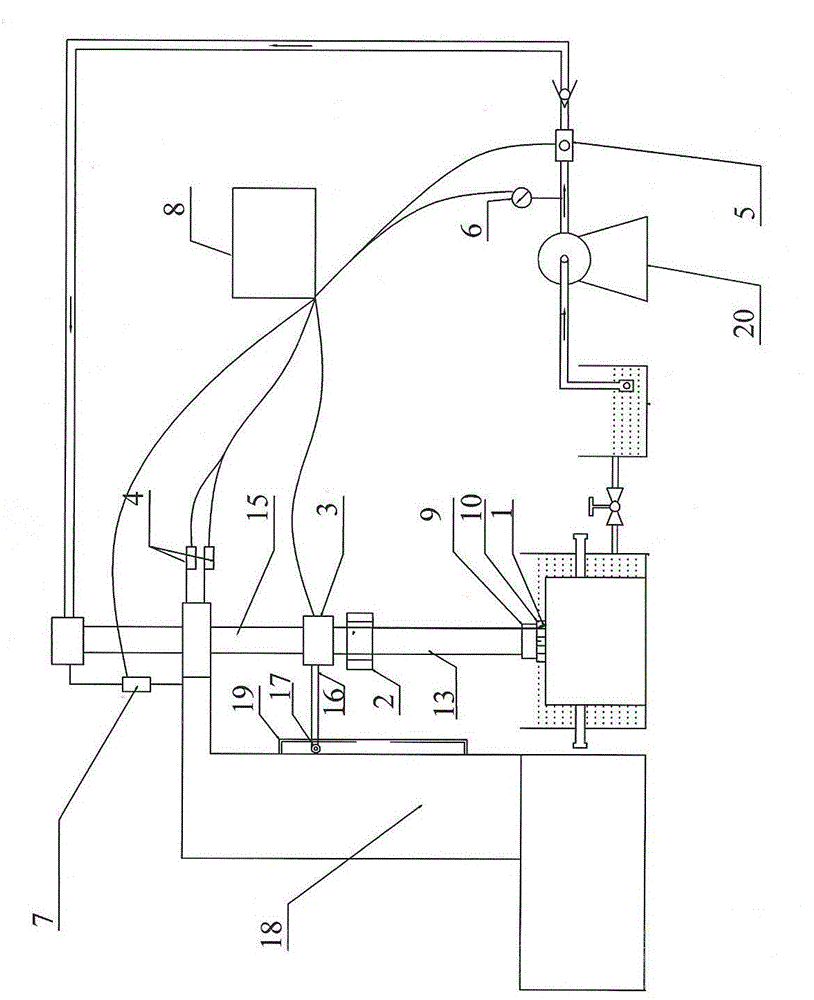

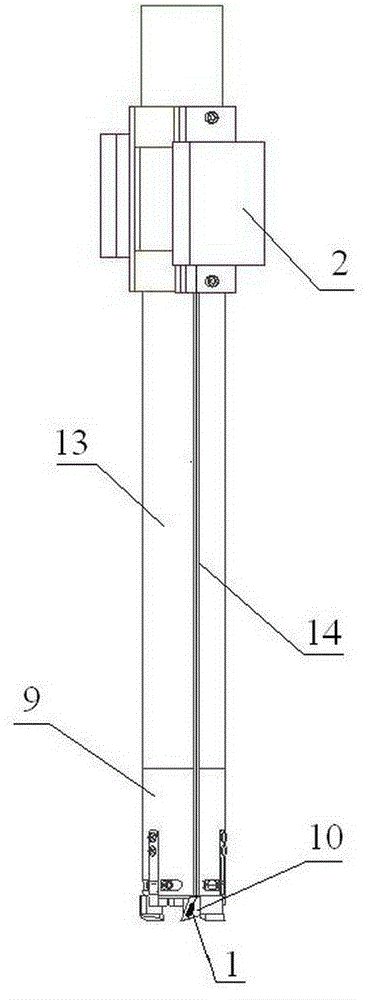

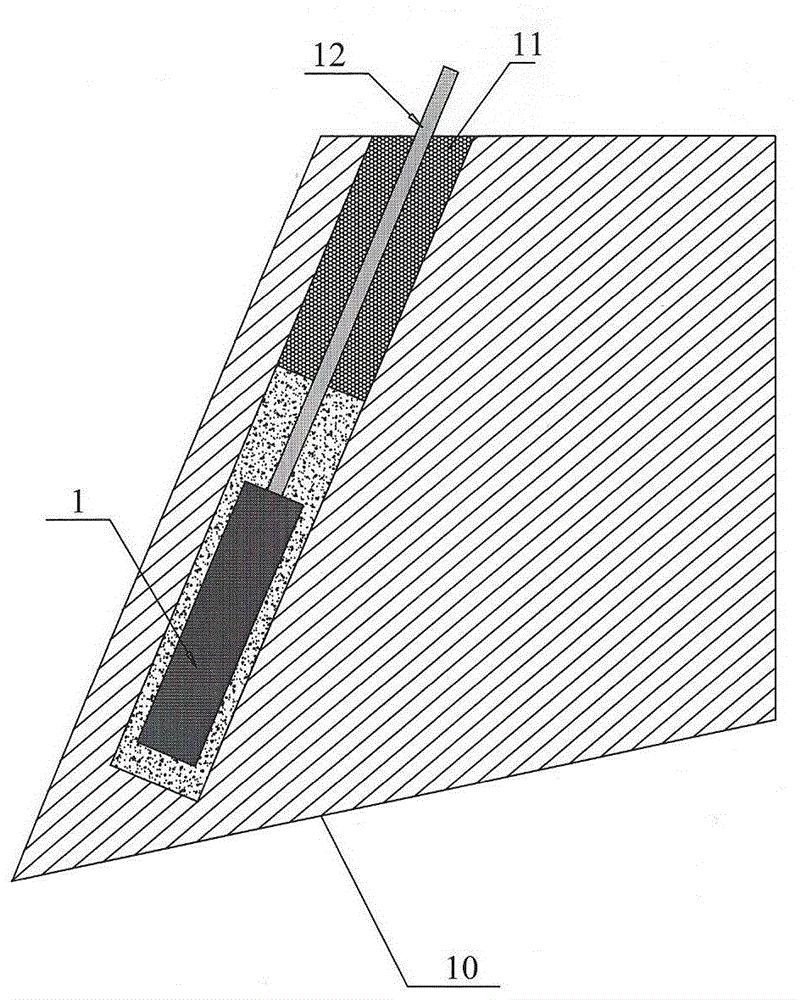

[0026] see figure 1 , figure 2 , image 3 and Figure 4 Shown:

[0027] The ice layer rotary drilling cutting heat and drilling parameter experimental device of the present invention is composed of thermocouple 1, wireless transmitter 2, torque sensor 3, two pressure sensors 4, flow meter 5, pressure gauge 6, stay rope displacement The sensor 7 and the computer assembly 8 are composed, wherein the thermocouple 1 is installed in the round hole 11 of the cutting tool 10 at the lower end of the drill bit 9, and the thermocouple 1 and the wireless transmitter 2 are connected by a connecting wire 12, and the wireless transmitter 2 is fixed on the drill bit. On the rod 15, the wireless transmitter 2 rotates together with the drill rod 15, the connecting wire 12 of the thermocouple 1 and the wireless transmitter 2 is arranged in the groove 14 provided on the drill bit 9 and the ice core pipe 13, and the two sides of the torque sensor 3 rotor The ends are respectively connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com