Engine supercharging mechanism and application thereof

An engine and drive shaft technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of reduced intake air volume, engine power reduction, and exhaust obstruction, etc., to achieve increased intake air volume and exhaust gas Smooth, full-burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

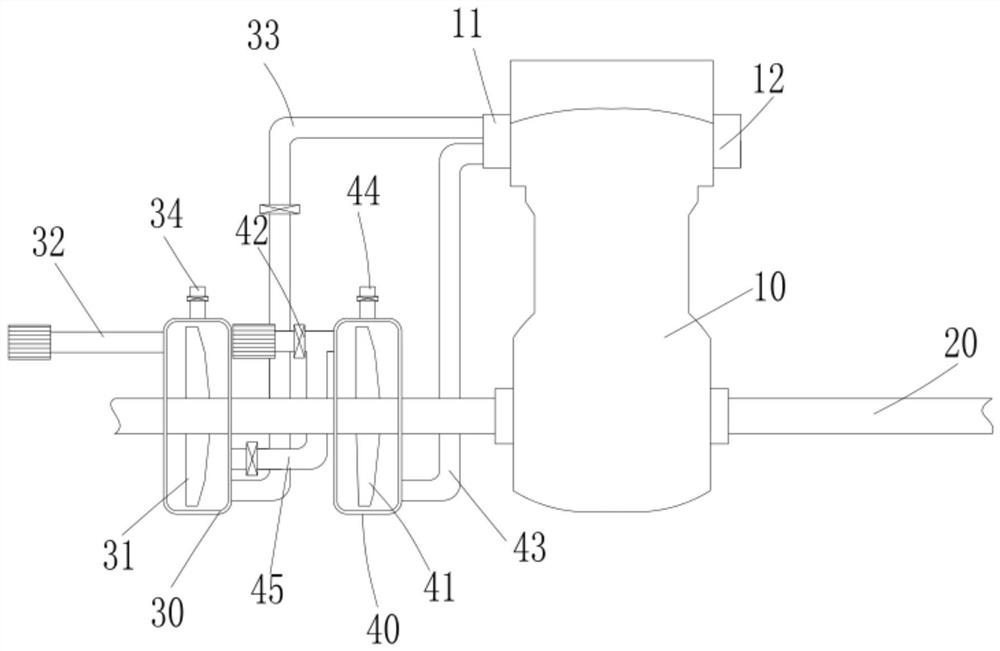

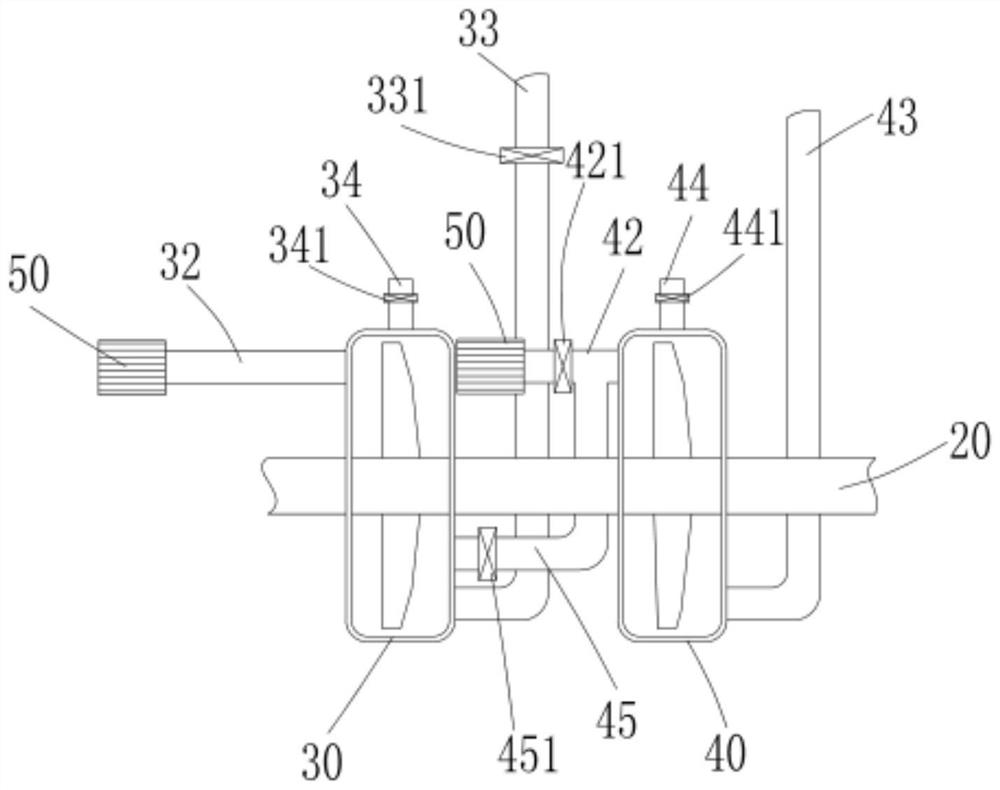

[0024] The present invention provides a technical solution: an engine supercharging mechanism includes an engine body 10, the engine body 10 is connected with a drive shaft 20, a first casing 30 is mounted on the drive shaft 20, and a first impeller is arranged in the first casing 30 31. The first impeller 31 is connected with the drive shaft 20; one end of the first casing 30 is provided with an air intake pipe, and the other end is provided with an air guide pipe, and the air guide pipe is connected with the intake valve 11 of the engine body 10; one end of the first casing 30 is provided with a The first air intake pipe 32 has a first air intake pipe 33 at the other end. The first air intake pipe 33 is connected to the intake valve 11 of the engine body 10 . A first exhaust pipe 34 is disposed on the upper side of the first housing 30 . A first solenoid valve 341 is installed on the gas pipe 34 .

[0025] Specifically, when the engine body 10 is working, the internal piston...

Embodiment 2

[0027] On the basis of Embodiment 1, a second casing 40 is installed on the drive shaft 20 , a second impeller 41 is disposed in the second casing 40 , the second impeller 41 is connected to the drive shaft 20 , and one end of the second casing 40 is disposed There is a second intake pipe 42 , and the other end is provided with a second air conduit 43 , and the second air conduit 43 is connected to the intake valve 11 of the engine body 10 .

[0028] Specifically, the engine body 10 can simultaneously drive the first impeller 31 and the second impeller 41 to rotate, and transport air into the engine body 10 through the first air duct 33 and the second air duct 43 to effectively increase the intake air volume.

Embodiment 3

[0030]On the basis of Embodiment 1, a second housing 40 is mounted on the drive shaft 20 , one end of the second housing 40 is provided with a second air intake pipe 42 , and the other end is provided with a second air conduit 43 , and the second air conduit 43 is connected to The engine body 10 is connected to the intake valve 11, the second casing 40 is provided with a second impeller 41, and the second impeller 41 is connected to the drive shaft 20; the upper side of the second casing 40 is provided with a second exhaust pipe 44, the second A second solenoid valve 441 is installed on the exhaust pipe 44; a third solenoid valve 331 is installed on the first air duct 33, and a third air intake pipe 45 is connected to the second air intake pipe 42. The third air intake pipe 45 is connected to the first shell The engine body 30 is connected, the second intake pipe 42 is installed with a fourth solenoid valve 421, and the third intake pipe 45 is equipped with a fifth solenoid val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com