Foam stacking and unstacking equipment

A foam and palletizing technology, applied in the field of palletizing and depalletizing equipment, can solve problems such as difficulty in meeting actual production needs and insufficient speed of automatic palletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

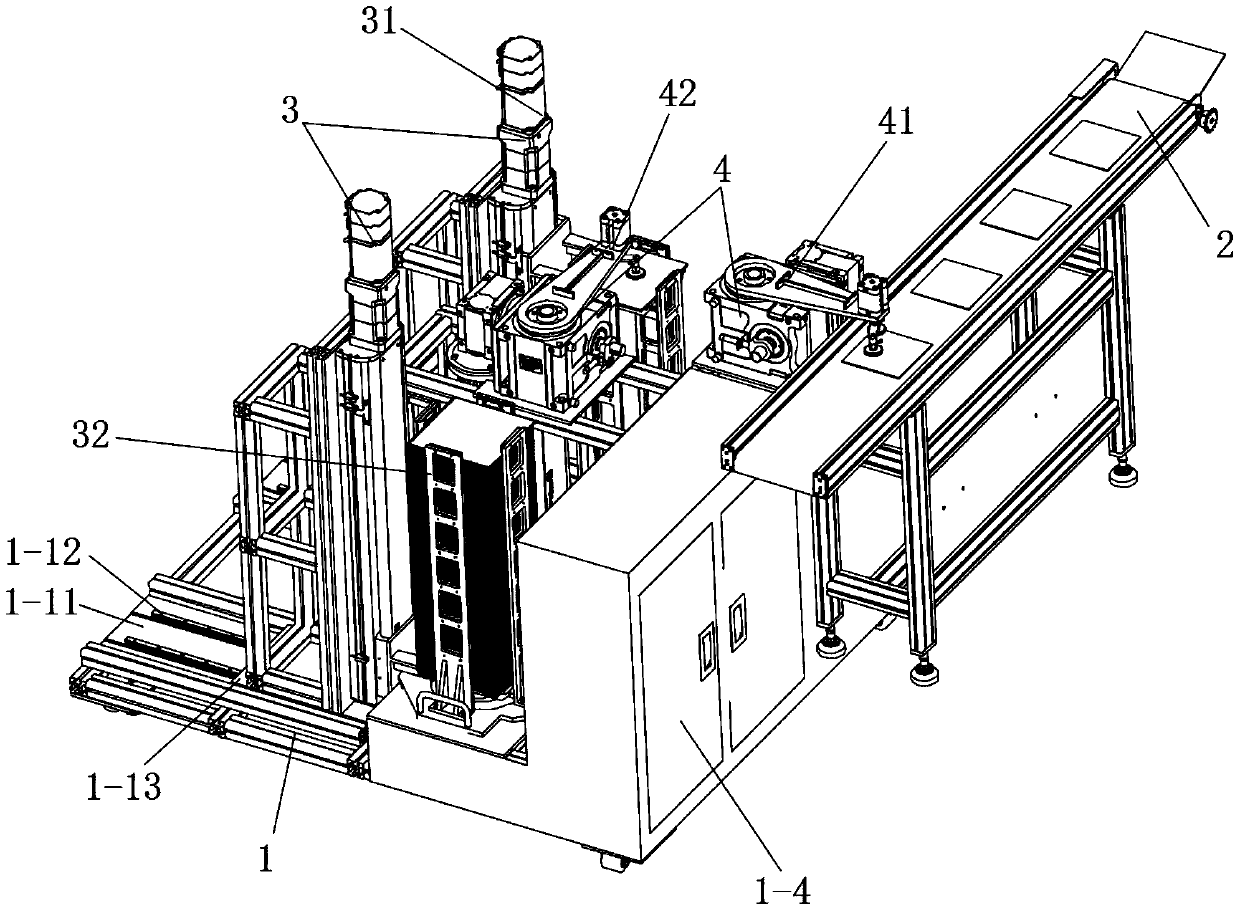

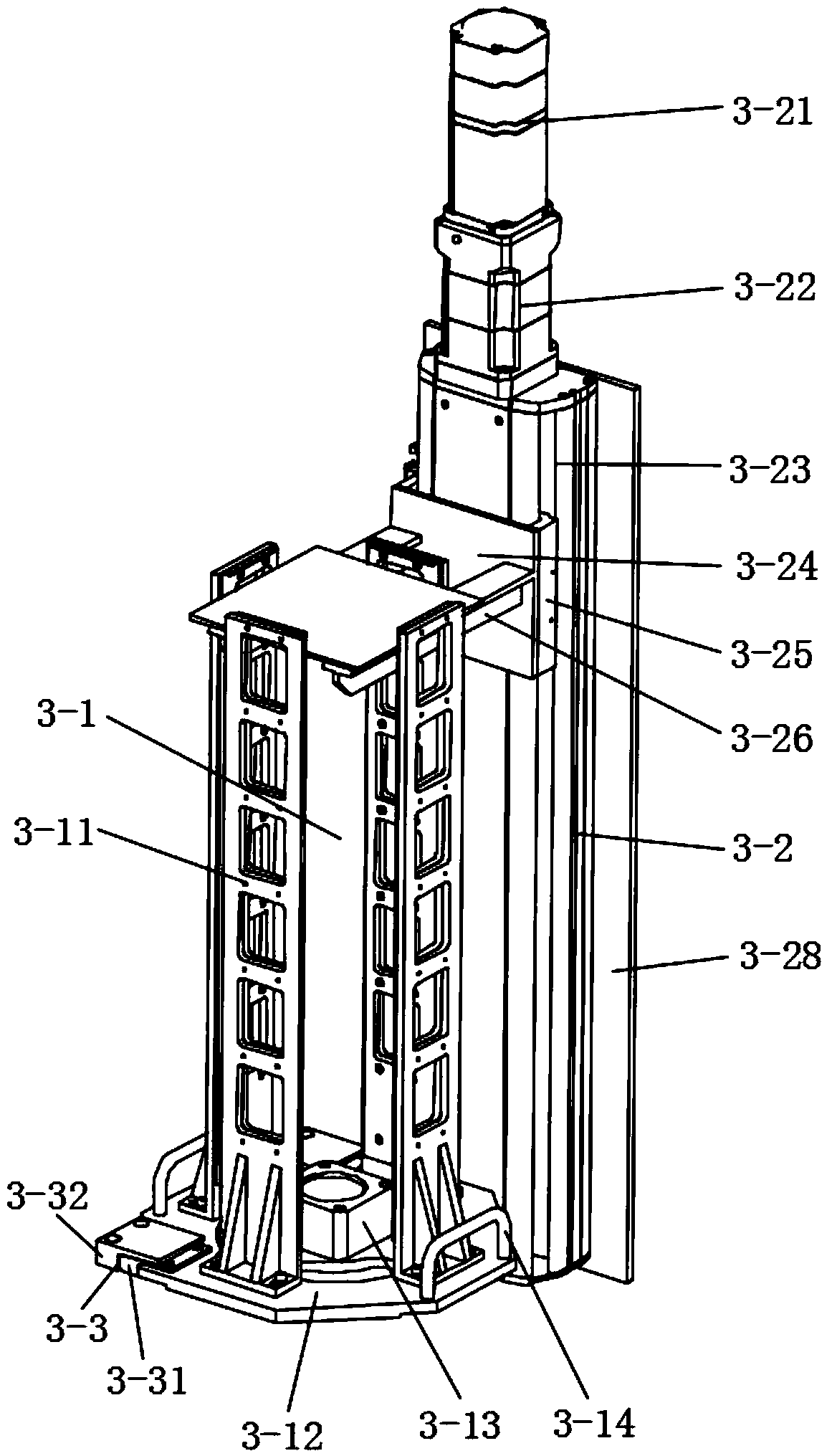

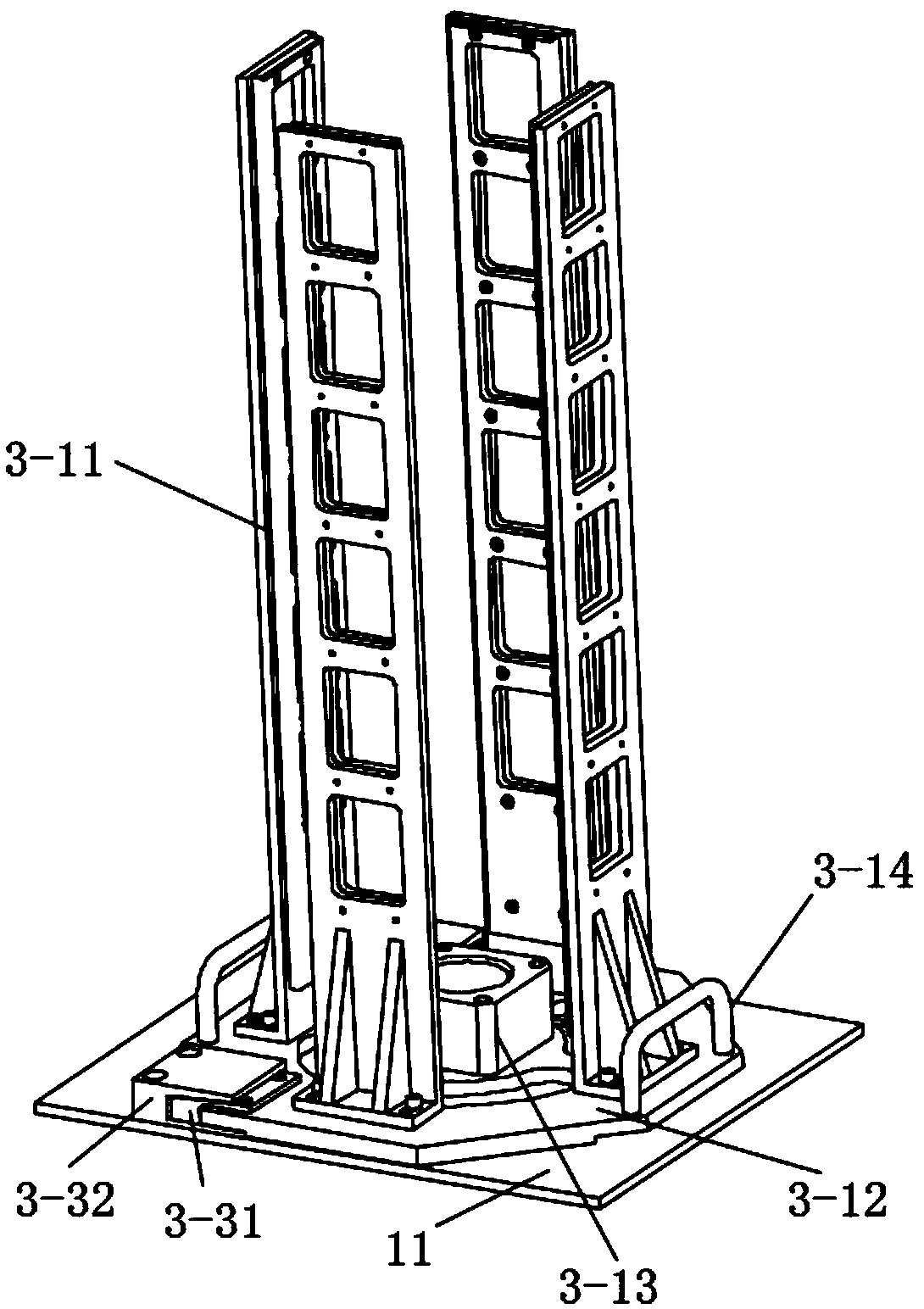

[0050] A kind of foam palletizing and depalletizing equipment, such as figure 1 As shown, it includes a support frame 1, a belt assembly line 2 for transporting foam on the side of the support frame, a stacking tool 3 and a robot 4 installed on the support frame, a detection system and a control system. The stacking tool 3 includes a mixed stacking tool 31 for cross-stacking the foam and the hard platen, and a hard platen stacking tool 32 for separately stacking the hard platen. The manipulator 4 includes a foam grasping manipulator 41 that transfers foam between the belt assembly line 2 and the mixed stacking tool 31, and a rigid platen grasper that transfers the hard platen between the hard platen stacking tool 32 and the mixed stacking tooling 31 manipulator42. The detection system is used to detect the operating status of the foam palletizing and depalletizing equipment, and send the detection information to the control system. The control system is used to receive the i...

Embodiment 2

[0086] In this embodiment, the equipment in Embodiment 1 is used for the palletizing of foam, such as Figure 10 As shown, in this embodiment, the belt assembly line is arranged at the rear end of the cutting station, and the cut foam is installed in a certain order and the distance interval is sequentially transported from right to left. In order to better understand this embodiment, the following Make a complete elaboration to the workflow of this embodiment:

[0087] Firstly, the tooling needs to be put in place, which includes the hard platen stacking tool 32 and the mixed stacking tool 31 in place.

[0088] The hard press plate stacking tool 32 is in place: firstly, the hard press plate is manually placed on the hard press plate stacking tool 32; Slide outside to reserve the installation position of the hard press plate stacking tool 32; secondly, push the hard press plate stacking tool 32 to the tool backing plate 11, and when the positioning block 3-31 touches the posi...

Embodiment 3

[0102] In this embodiment, the equipment in Embodiment 1 is used for the destacking of foam, as Figure 11 As shown, in this embodiment, the rear end of the belt assembly line is arranged with a grabbing robot for information printing. In order to better understand this embodiment, the following is a complete description of the workflow of this embodiment:

[0103] First of all, the tooling needs to be in place, which includes the mixed stacking tool 31 and the hard platen stacking tool 32 in place.

[0104] The mixed stacking tool 31 is in place: first slide the module bracket 1-5 outward, slide the fork frame 3-24 connected to the linear module 3-23 outward, and reserve the installation position of the mixed stacking tool 31; then put the The cured hard platen-foam pile mixed stacking tooling 31 is pushed to the tooling backing plate 11, and when the positioning block 3-31 touches the positioning plate 3-32, the stacking bottom plate 3-12 and the tooling backing plate 11 Al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com