Overturning and suspension device for projectile body vertical mode test and use method thereof

A modal test, suspension device technology, applied in the directions of transportation and packaging, load suspension components, etc., can solve the problems of non-compliance with safe operation regulations, high risks, and high cost of motor mechanism turnover, and achieve stable and controllable turnover process. The effect of low cost, high reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

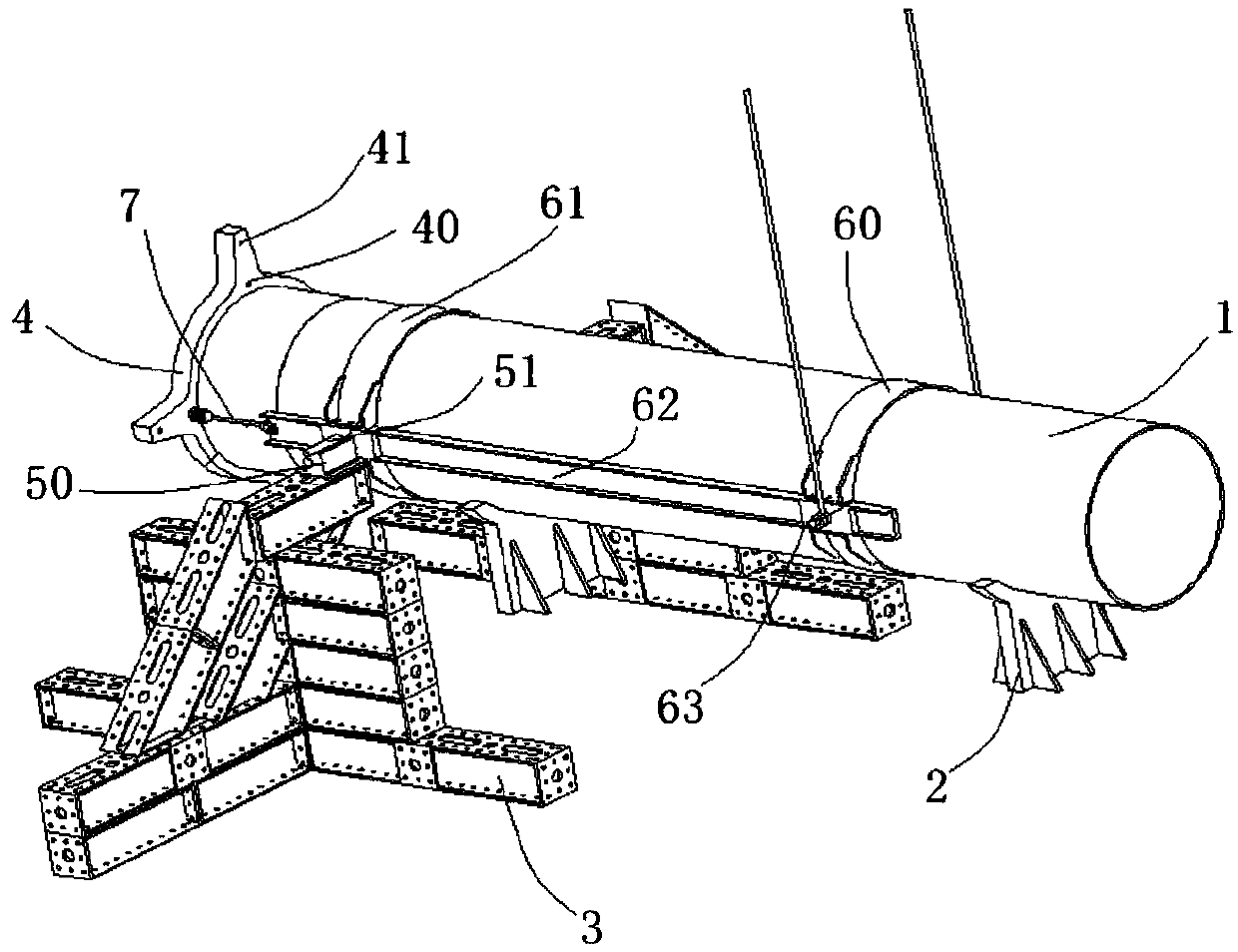

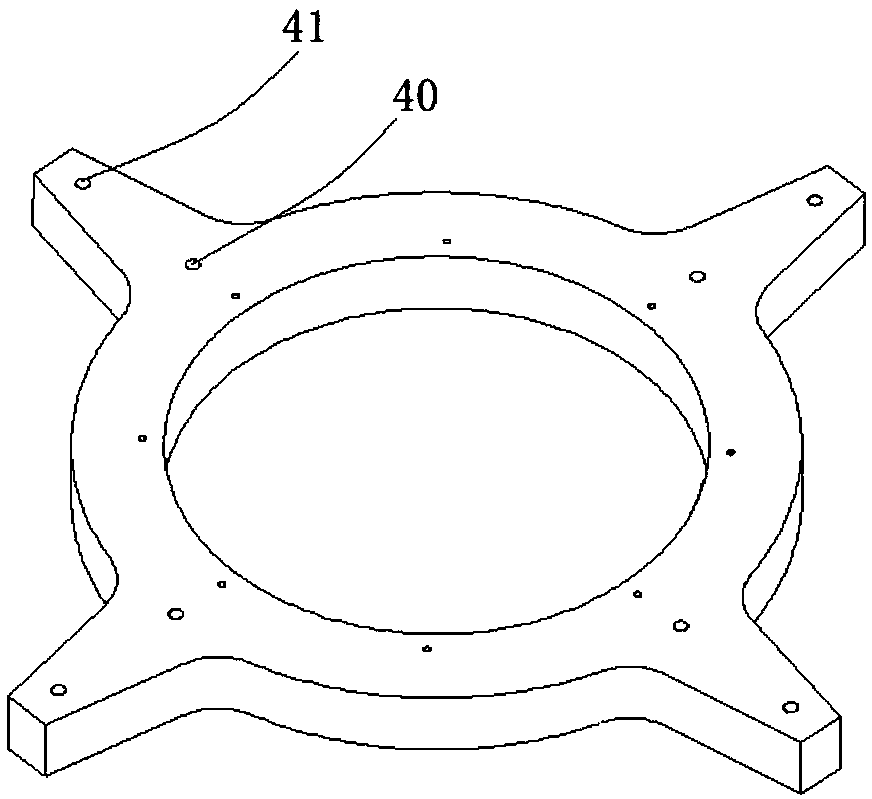

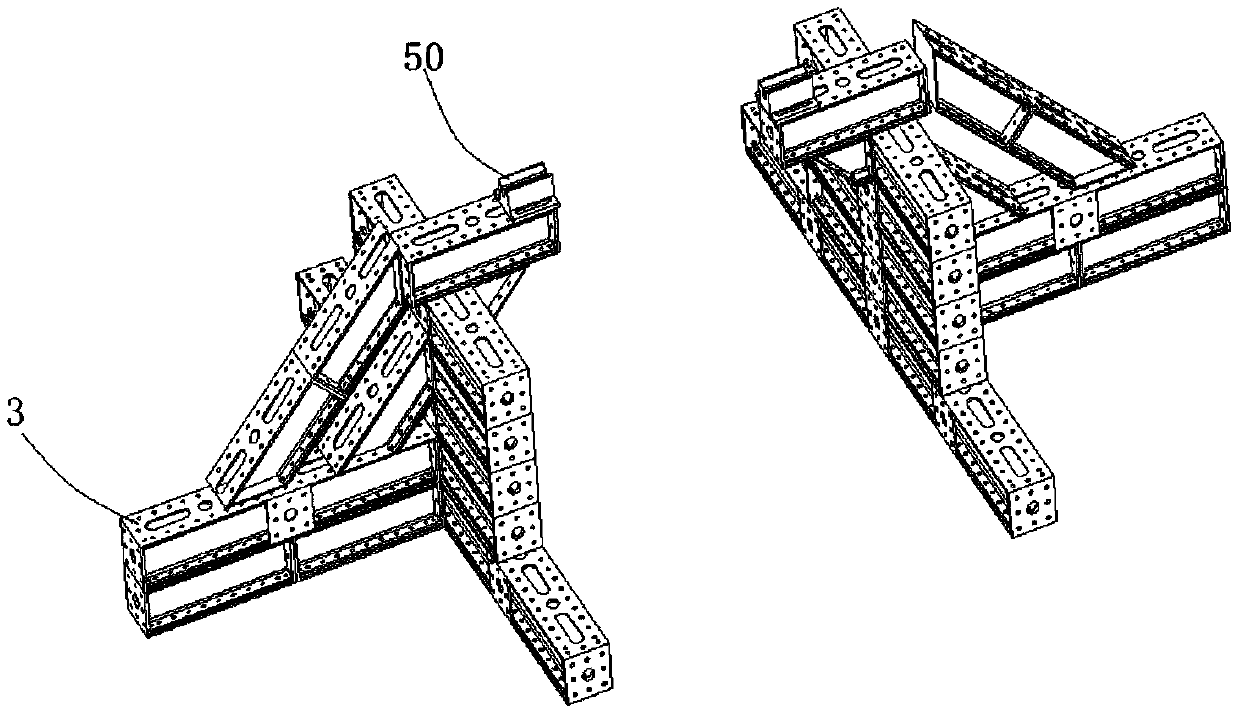

[0036] see figure 1 As shown, the embodiment of the present invention provides a flip suspension device for the vertical modal test of the projectile, including a bracket 2, two support platforms 3, a rotating assembly and a suspension 4, and the bracket 2 is used to support the projectile 1. Increase or decrease the number according to the actual situation. The two support platforms 3 are used to provide a rotating support platform for the projectile 1. In actual use, they are symmetrically arranged on both sides of the projectile 1. The rotating assembly includes a fixed piece and a symmetrical Rotating parts arranged on both sides of the fixing part, one end of the rotating part is connected with the fixing part, and the other end is fixed on the supporting platform 3, the fixing part is used to be set on the elastic body 1, when the fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com