A kind of preparation method of polyurethane urea elastic fiber with high heat setting efficiency

A technology of polyurethane urea and elastic fiber is applied in the manufacture of spandex fiber and the manufacture of new functional spandex fiber. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

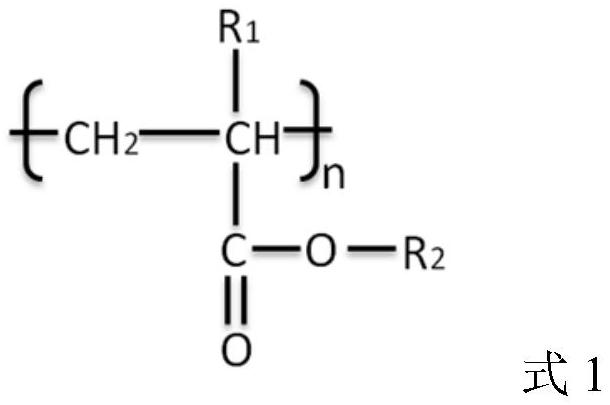

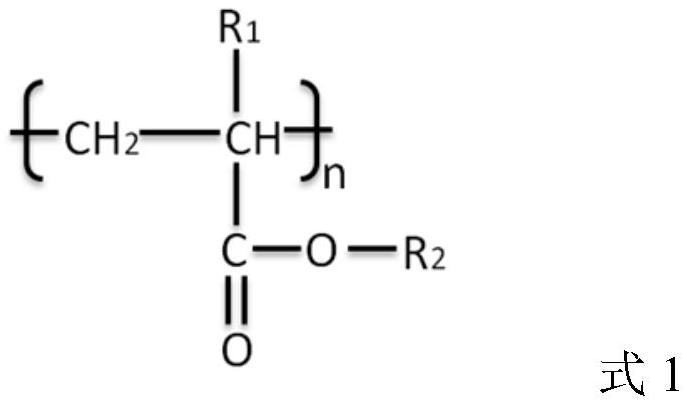

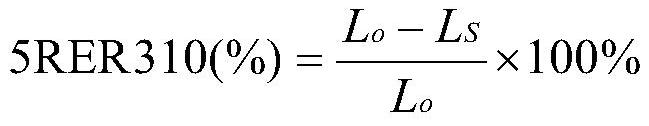

Method used

Image

Examples

Embodiment 1

[0047] 1) Mix polytetramethylene ether glycol and 4,4'-diphenylmethane diisocyanate and react at 90°C for 120 minutes to prepare a prepolymer, in which 4,4'-diphenylmethane diisocyanate and poly The molar ratio of tetramethylene ether glycol is 1.70:1;

[0048] 2) Dissolve ethylenediamine and propylenediamine in a molar ratio of 4:1 into the solvent N,N-dimethylacetamide, and then add diethylamine with a diamine molar content of 15% to form a concentration of 6.00% by mass The mixed amine solution; then the mixed amine solution is added to the prepolymer solution and stirred, wherein the molar ratio of the amine group to the isocyanate group is 1.05:1, and the reaction is carried out to prepare the secondary polymerization stock solution ;

[0049]3) 0.5wt% of 2-(2'-hydroxyl-3',5'-di-tert-butylphenyl)-benzotriazole), 0.5wt% of bis(N,N-dimethylhydrazide Amino 4-phenyl)methane, 0.1wt% magnesium stearate, 0.5wt% titanium dioxide were added to N,N-dimethylacetamide and ground fo...

Embodiment 2

[0053] 20D polyurethaneurea elastic fibers having high heat-setting efficiency were obtained in the same manner as described in Example 1 except that the content of polymethylmethacrylate was 5 wt%.

Embodiment 3

[0055] 20D polyurethaneurea elastic fibers having high heat-setting efficiency were obtained in the same manner as described in Example 1 except that the polymethyl methacrylate content was 15 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com