Preparation method of polyurethane urea elastic fibers with high thermal setting efficiency

A polyurethane urea and elastic fiber technology, which is used in the manufacture of spandex fiber and the manufacture of new functional spandex fiber, can solve the problems of the negative impact of fiber modulus and elasticity, reduce energy consumption, improve shaping efficiency, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1) Mix polytetramethylene ether glycol and 4,4'-diphenylmethane diisocyanate and react at 90°C for 120 minutes to prepare a prepolymer, in which 4,4'-diphenylmethane diisocyanate and poly The molar ratio of tetramethylene ether glycol is 1.70:1;

[0048] 2) Dissolve ethylenediamine and propylenediamine in a molar ratio of 4:1 into the solvent N,N-dimethylacetamide, and then add diethylamine with a diamine molar content of 15% to form a concentration of 6.00% by mass The mixed amine solution; then the mixed amine solution is added to the prepolymer solution and stirred, wherein the molar ratio of the amine group to the isocyanate group is 1.05:1, and the reaction is carried out to prepare the secondary polymerization stock solution ;

[0049]3) 0.5wt% of 2-(2'-hydroxyl-3',5'-di-tert-butylphenyl)-benzotriazole), 0.5wt% of bis(N,N-dimethylhydrazide Amino 4-phenyl)methane, 0.1wt% magnesium stearate, 0.5wt% titanium dioxide were added to N,N-dimethylacetamide and ground fo...

Embodiment 2

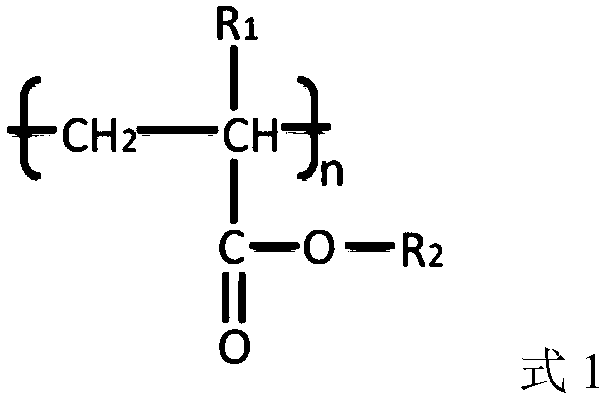

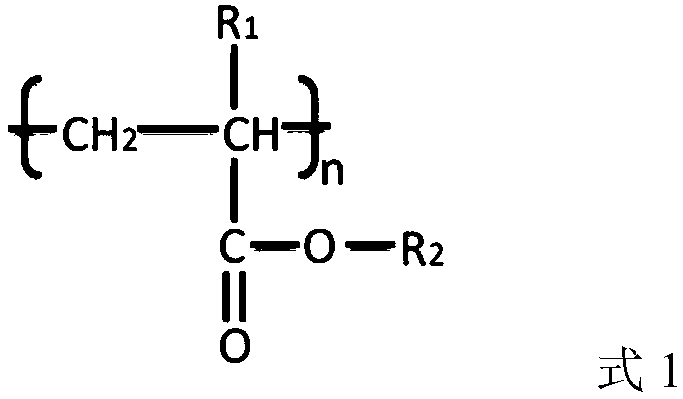

[0053] 20D polyurethaneurea elastic fibers having high heat-setting efficiency were obtained in the same manner as described in Example 1 except that the content of polymethylmethacrylate was 5 wt%.

Embodiment 3

[0055] 20D polyurethaneurea elastic fibers having high heat-setting efficiency were obtained in the same manner as described in Example 1 except that the polymethyl methacrylate content was 15 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com