Sheet mica electrode combined intelligent iron and ironing method

A mica sheet and electrode technology, applied in hand irons, washing devices, textiles and papermaking, etc., can solve the problems of scale accumulation, blockage, and affect the appearance of electric heating tubes, so as to reduce the generation of scale, reduce the risk of pipe bursting, reduce water pollution, etc. The effect of fine and uniform fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

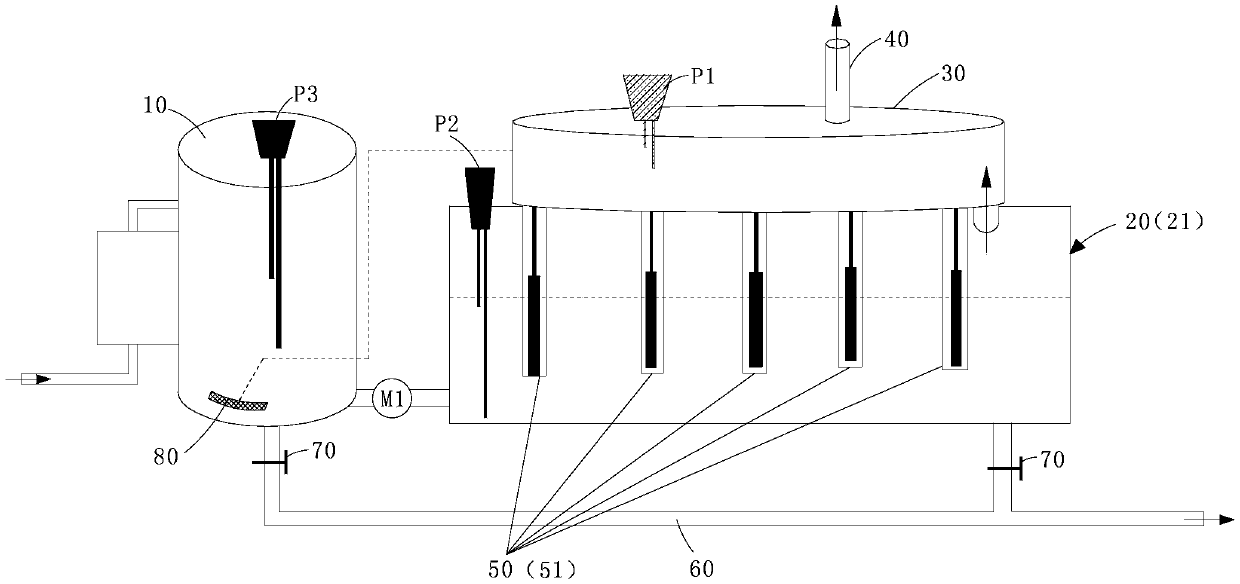

[0031] refer to figure 1 The smart iron with mica sheet electrode combination in this embodiment includes a water tank 10 connected in sequence with a steam generator 20, a steam collector 30, a steam outlet 40, and multiple sheets for heating the water in the steam generator 20 when energized. Independently powered mica sheet electrode 50, the water tank 10 is provided with a water softener for softening water, the steam outlet 1 is arranged on the steam collector 30, and the mica sheet electrode 50 is arranged in the steam generator 20 to contact with water, or is located in Steam generator 20 surface. The purified water in the water tank 10 is transported to the steam generator 20 by the feed water pump M1 for heating, the water in the steam generator 20 is heated, and the generated steam enters the steam collector 30. When the pressure in the steam generator 20 meets the set value , press the button controlling the spray solenoid valve, the spray solenoid valve will be op...

Embodiment 2

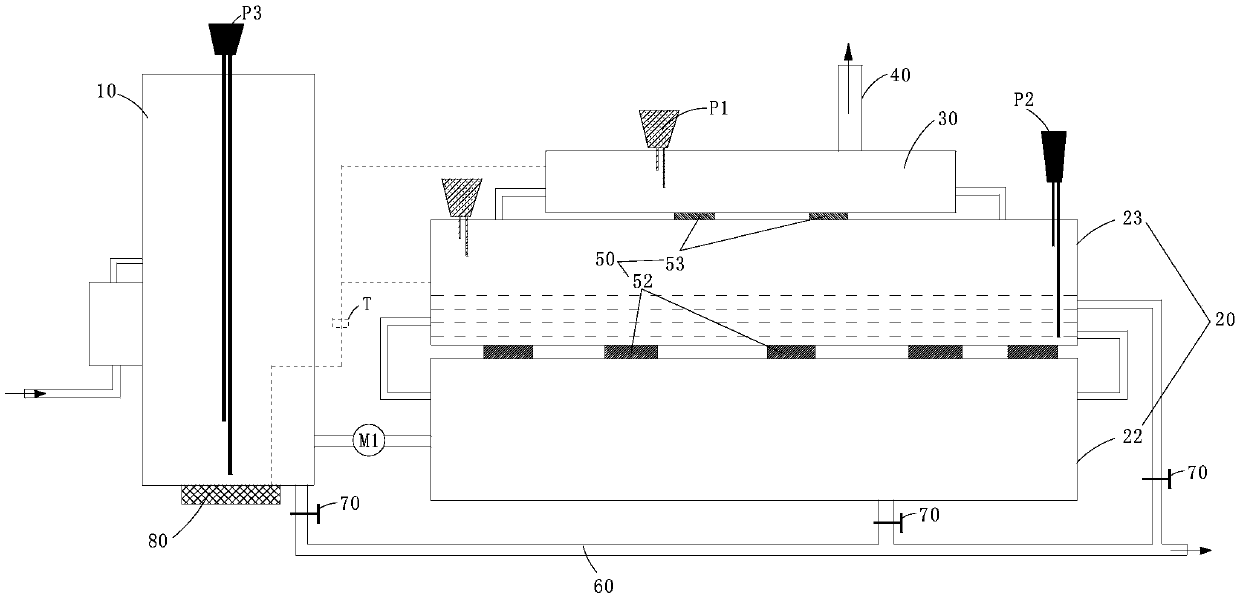

[0052] Such as figure 2 As shown, the steam generator 20 of this embodiment includes a second steam generator 22 and a third steam generator 23 arranged on the second steam generator 22, and the water entering from the water tank 10 is preheated by the second steam generator 22. After heating, it enters the third steam generator 23 , and the steam generated by heating the water in the third steam generator 23 enters the steam collector 30 .

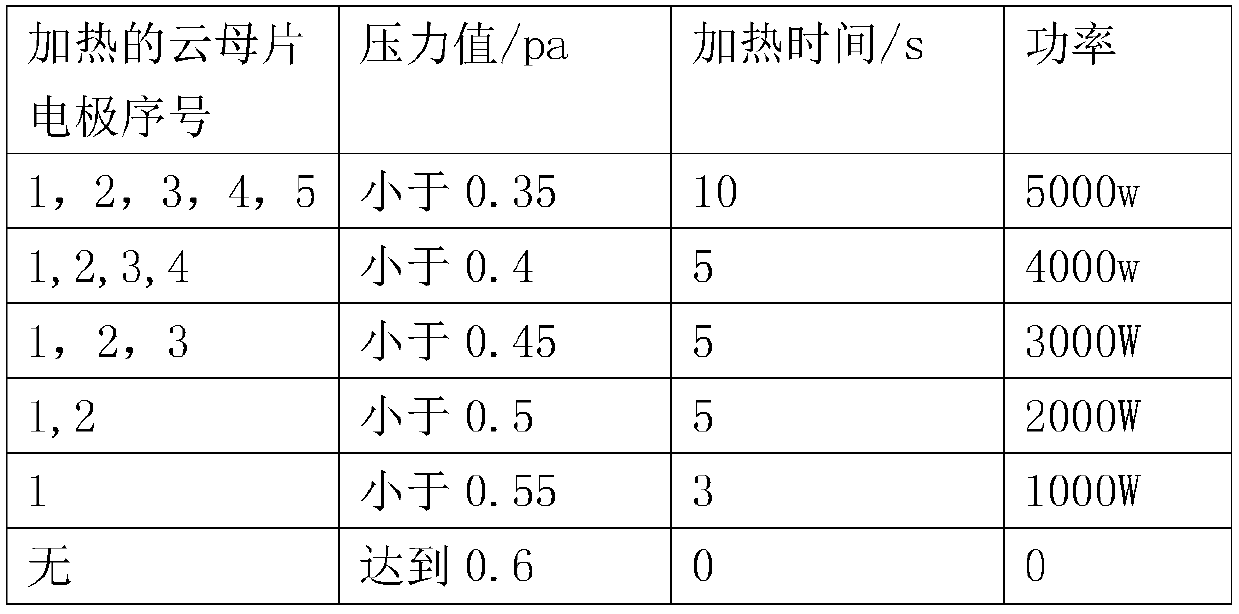

[0053] Preferably, the steam collector 30, the third steam generator 23, and the second steam generator 22 are stacked up and down, and the mica sheet electrode 50 includes a plurality of second mica sheet electrodes 52 arranged at intervals, and the plurality of second mica sheet electrodes 52 Flatly interposed between the second steam generator 22 and the third steam generator 23, to heat the second steam generator 22 and the third steam generator 23 simultaneously when energized, here, the second mica sheet electrode 52 Take 5 as an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com