System and method for adjusting boiler feed water oxygen adding amount

A technology for boiler feed water and oxygen addition, which is applied in the control/regulation system, flow control, non-electric variable control, etc., and can solve the problems of tight interference of sampling system, frequent fluctuation of water supply operating parameters, and unsuitable oxygen addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

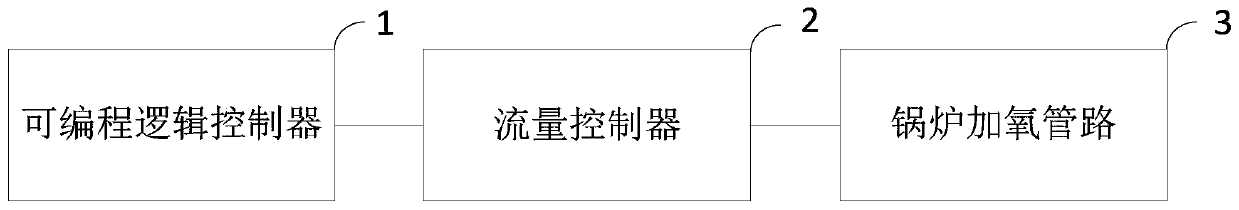

[0028] figure 1 It is a block diagram of a system for adjusting the amount of oxygen added to boiler feed water provided by Embodiment 1 of the present invention. The system for adjusting the amount of oxygen added to boiler feed water provided by this implementation can be applied to the situation of precisely controlling the amount of oxygen added to boiler feed water. places, including:

[0029] A programmable logic controller 1, the programmable logic controller 1 is arranged on the boiler oxygenation pipeline 3, the programmable logic controller 1 is used to receive the control signal and generate a programmable logic controller according to the control signal 1 instruction.

[0030] In this embodiment, the programmable logic controller 1 is a digital operation electronic system specially designed for application in industrial environments. It uses a programmable memory to store instructions for performing logic operations, sequence control, timing, counting, and arithm...

Embodiment 2

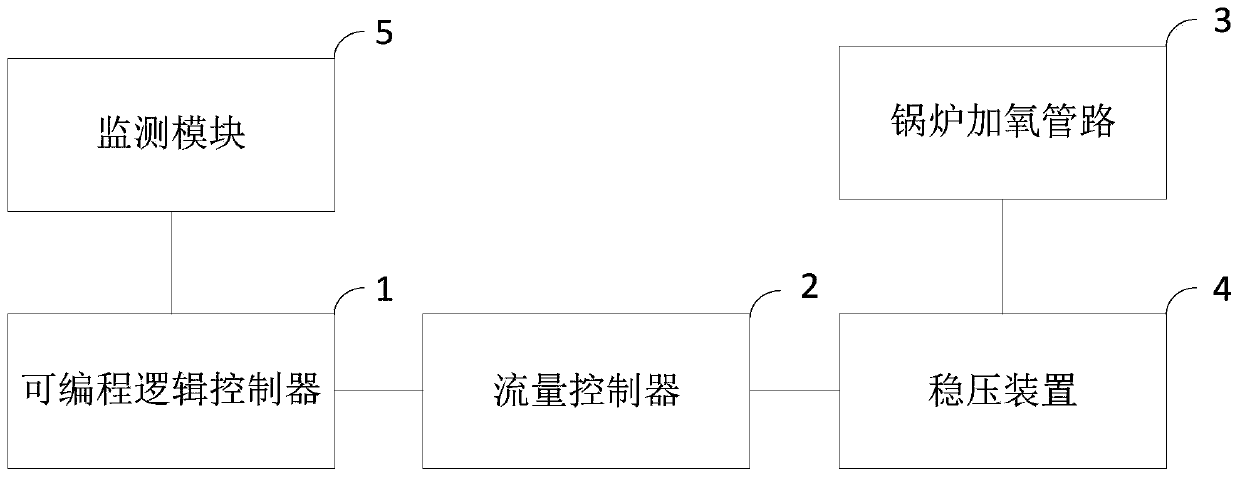

[0035] figure 2 A block diagram of a system for adjusting the amount of oxygen added to boiler feed water provided by Embodiment 2 of the present invention. This embodiment adds other functional modules on the basis of Embodiment 1 and makes a detailed description. The embodiment provides a A system for adjusting the amount of oxygen added to boiler feed water can be applied to the situation of precisely controlling the amount of oxygen added to boiler feed water, specifically, including:

[0036]A programmable logic controller 1, the programmable logic controller 1 is arranged on the boiler oxygenation pipeline 3, the programmable logic controller 1 is used to receive the control signal and generate a programmable logic controller according to the control signal 1 instruction.

[0037] A flow controller 2, the flow controller 2 is connected with the programmable logic controller 1, and is used to adjust the flow rate of oxygenation according to the instructions of the progr...

Embodiment 3

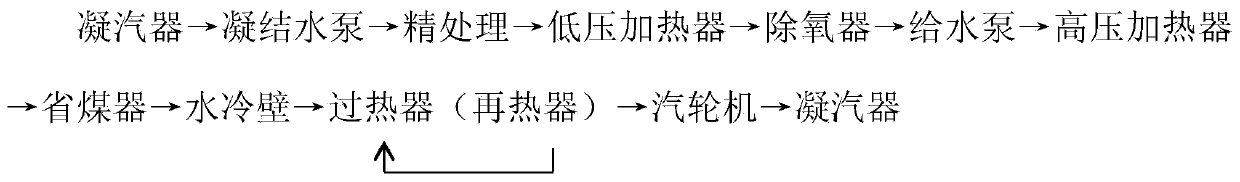

[0053] Figure 4 It is a schematic flow chart of a method for adjusting the amount of oxygen added to boiler feed water provided by Embodiment 3 of the present invention. The method for adjusting the amount of oxygen added to boiler feed water provided in this implementation can be applied to the situation of precisely controlling the amount of oxygen added to boiler feed water. places, including:

[0054] Step 310, acquiring various real-time data in the boiler and generating control signals according to the real-time data.

[0055] In this embodiment, a plurality of internal real-time data of the boiler are obtained, and the various real-time data include: feed water flow rate, feed water dissolved oxygen and feed water hydrogen conductivity.

[0056] Step 320, receiving a control signal and generating a PLC instruction according to the control signal.

[0057] In this embodiment, the following control parameters are set and adjusted: Feed water dissolved oxygen set value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com