A high-pressure water-assisted rock-breaking system and construction method for tunnel boring machines

A tunnel boring machine, high-pressure water technology, used in tunnels, earth-moving drilling, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

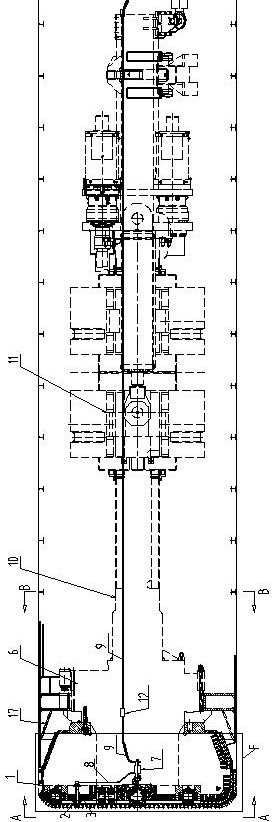

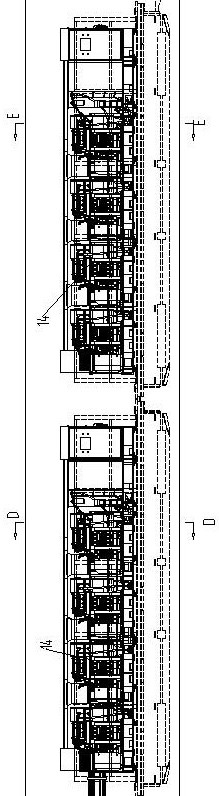

[0037] Example 1, such as Figure 1-4 As shown, a high-pressure water-assisted rock-breaking system for tunnel boring machines includes a softening treatment system, a power system, a conveying system and a high-pressure injection system connected in sequence; the liquid inlet end of the high-pressure injection system is connected with the conveying system, and the high-pressure The liquid outlet of the injection system is connected with the cutter head 1, the softening treatment system is connected with a water source, and the power system provides power for the conveying system. The external water source enters the softening treatment system for filtration and softening treatment, and then under the action of the power system, the treated atmospheric pressure water is converted into high-pressure water and sent to the delivery system. The high-pressure water enters the high-pressure injection system through the delivery system to form a high-pressure water jet. Rock breaking...

Embodiment 2

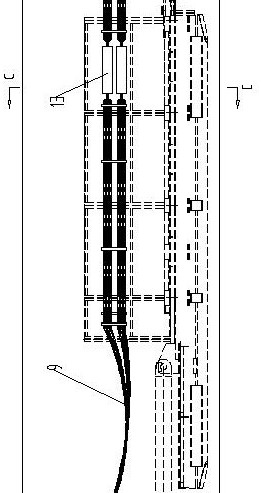

[0038] Example 2, such as Figure 5 As shown, a high-pressure water auxiliary rock-breaking system for tunnel boring machines, the high-pressure injection system includes a protection assembly 2 and a water spray mechanism 3, the protection assembly 2 is fixedly arranged on the front end surface of the cutter head 1, and the water spray mechanism One end of 3 is located in the protection assembly 2, and the other end is fixed on the back of the cutter head 1, and the water spray mechanism can be disassembled from the cutter head back, which is convenient for maintenance and replacement of the water spray mechanism. The water inlet end of the water spray mechanism 3 is connected with the conveying system, and the cutter head 1 is connected with the main drive 6 arranged in the host machine 17 . The protection component 2 and the water spray mechanism 3 correspond one-to-one. According to the needs, multiple protection components 2 and water spray mechanisms 3 can be installed o...

Embodiment 3

[0043] Example 3, such as figure 1 As shown, a high-pressure water-assisted rock-breaking system for tunnel boring machines, the conveying system includes a high-pressure rotary joint 7, a rotating high-pressure pipe 8 and a fixed high-pressure pipe 9, and the high-pressure rotary joint 7 is fixedly arranged on the back of the cutter head 1 , the water outlet end of the high-pressure rotary joint 7 is connected with the high-pressure injection system through the rotating high-pressure pipe 8, and the rotating high-pressure pipe 8 rotates synchronously with the cutter head under the action of the main drive, and the water inlet end of the high-pressure rotary joint 7 is connected with the fixed high-pressure pipe 9 The high-pressure water in the fixed high-pressure pipe changes from the axial water to the radial water through the high-pressure rotary joint, and enters the high-pressure injection system in a branch. The high-pressure rotary joint can withstand the highest pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com