A synthesis device and method for polycrystalline phosphorous germanium zinc in a single temperature zone

A synthesis device, synthesis method technology, applied in the direction of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the explosion danger of synthetic quartz tube, it is difficult to obtain accurate stoichiometric ratio polycrystalline material, ZGP polycrystalline Problems such as difficulty in raw materials, to achieve the effects of simple structure, reduced risk of tube burst, and controllable synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

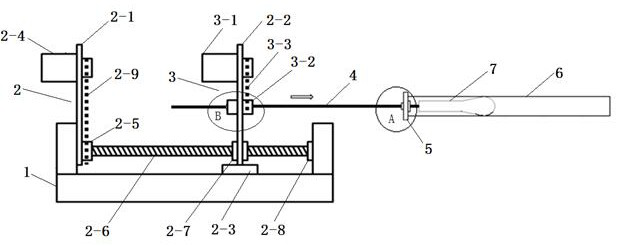

[0031] Such as Figure 1 to Figure 4 As shown, a single-temperature-zone phosphorus-germanium-zinc polycrystalline synthesis device includes a support platform 1 , a propulsion device 2 , a rotation device 3 , a rotary propulsion tube 4 , a flange 5 , a quartz tube 6 , and a synthesis inner tube 7 .

[0032] The propulsion device 2 includes support plate Ⅰ2-1, support plate Ⅱ2-2, slider 2-3, propulsion motor 2-4, pulley Ⅰ2-5, lead screw 2-6, lead screw nut 2-7, bushing 2- 8.

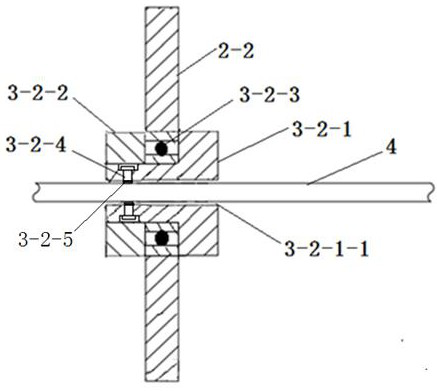

[0033] The rotating device 3 includes a rotating motor 3-1, a rotating assembly 3-2, and the rotating assembly 3-2 includes a pulley II 3-2-1, a lock nut 3-2-2, a bearing 3-2-3 and a screw 3-2 -4.

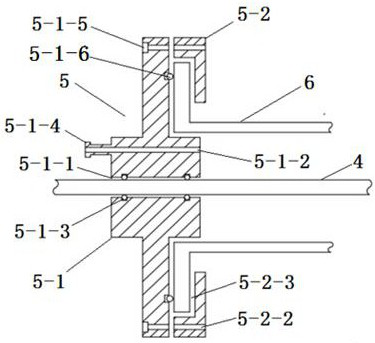

[0034] Flange 5 is made up of upper flange 5-1 and lower flange 5-2, both of upper flange 5-1 and lower flange 5-2 are circular bodies, at the center of the front and back of upper flange 5-1 , symmetrically provided with circular convex surfaces, the peripheral surfaces of the two circular convex surfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com