Energy harvesting type speed reducing mechanism

A deceleration mechanism and collection type technology, applied in electromechanical devices, controlling mechanical energy, roads, etc., to achieve the effects of high reliability, simple structure, and improved power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

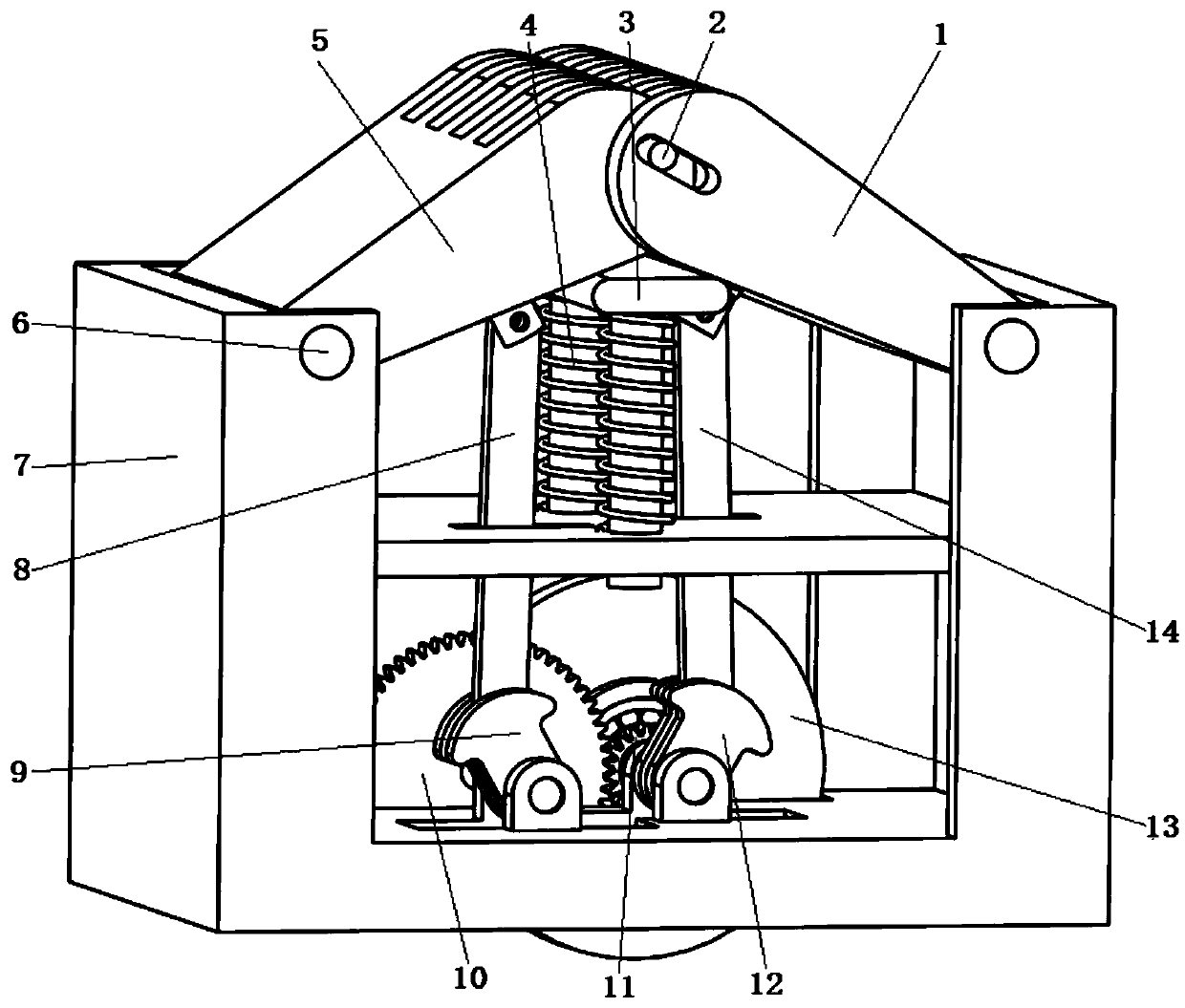

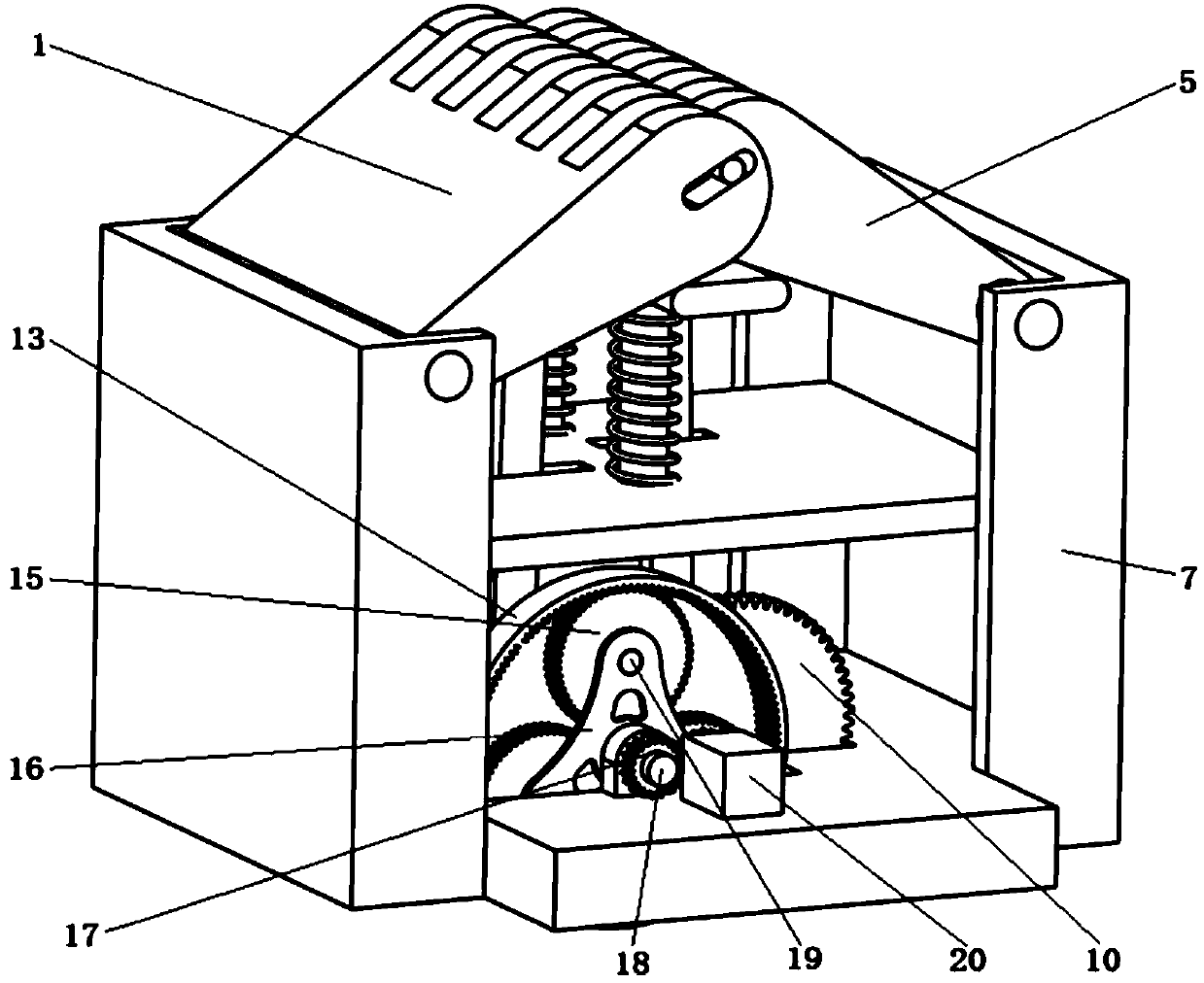

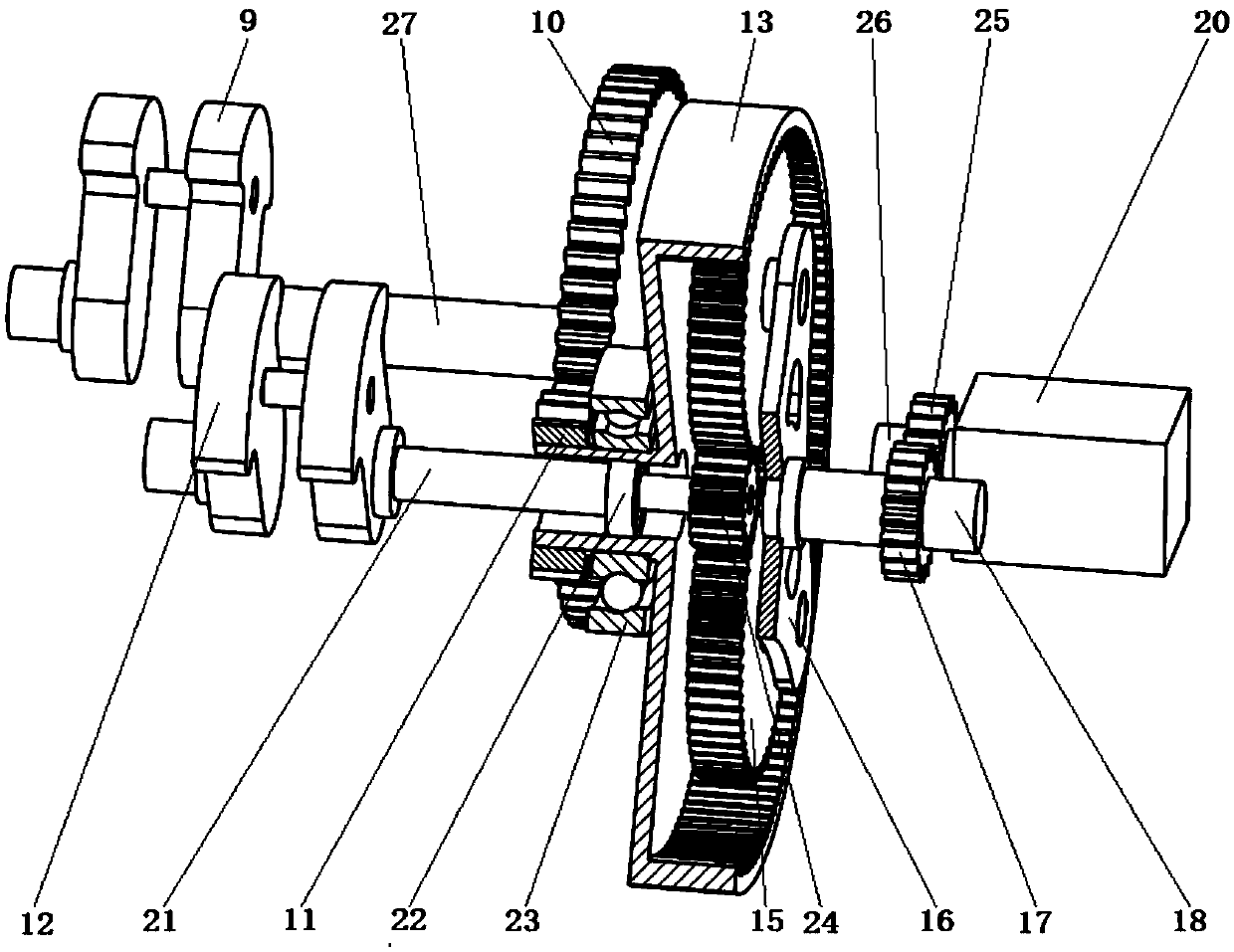

[0028] The energy harvesting speed reduction mechanism is provided with a speed coupling device, which includes a speed reduction belt part, a motion conversion part and a speed coupling part. The deceleration belt part includes two front passing surfaces 1 that are embedded in each other's tooth gaps and pinned by bolts, which can swing around the fixed shaft 6, the reverse passing surface 5, and the bolt 2 that connects the comb teeth. Sliding in the elongated latch hole of front and back crossing the vehicle surface, there is a horizontal plate 3 that provides the damping force and reset force of the speed bump below the speed bump, and there is a return spring 4 between the cross plate 3 and the middle plate of the chassis 7. The motion conversion part can convert up and down motion into continuous rotary motion. It is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com