Prefabricated assembly type double-steel-plate concrete shear wall connecting assembly and using method thereof

A concrete shear wall and prefabricated assembly technology, applied in the direction of building, building structure, etc., can solve the problems of difficult pouring of concrete, difficult to fix the upper wall, difficult to meet the requirements of the connection method, etc., and achieves convenient calculation and reliable connection quality. , the effect of the clear force of the component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

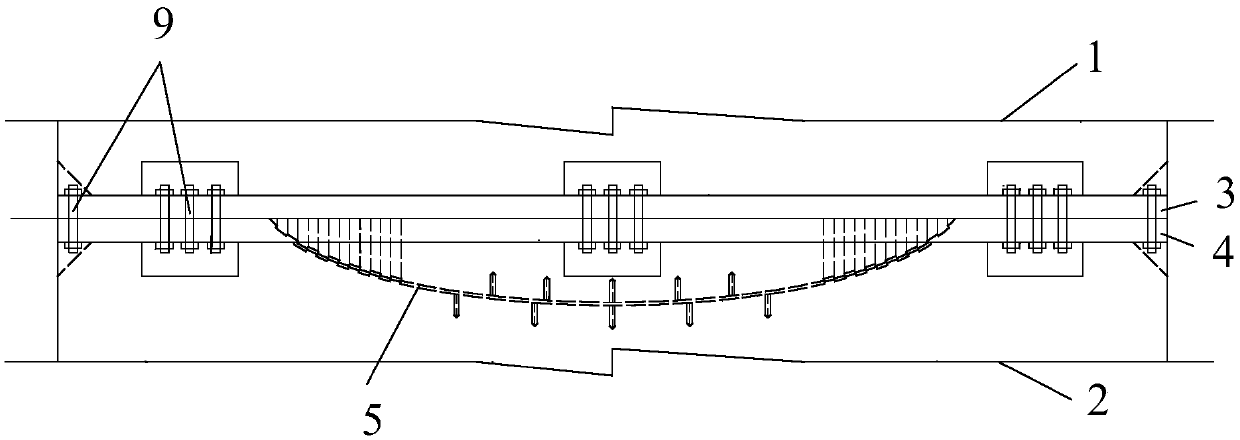

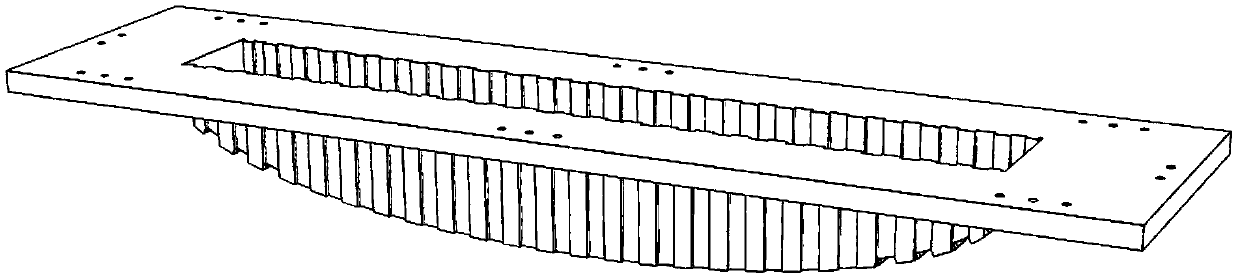

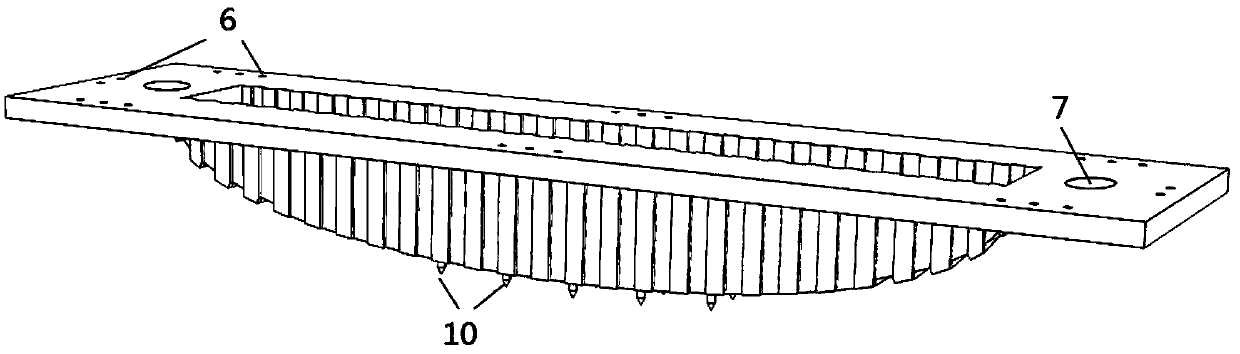

[0042] Such as Figure 1-5 As shown, a kind of prefabricated assembly type double steel plate concrete shear wall connection assembly described in the present invention comprises base plate 3, roof plate 4 and some bolts 9, and described base plate and roof plate are provided with some bolt holes 6, and the size is the same as that of corresponding bolts Matching, used to connect the top plate of the lower wall and the bottom plate of the upper wall. The bolts are high-strength bolts.

[0043] The top plate and the bottom plate are located at the top and bottom of the wall respectively, and play the role of connecting the upper and lower walls and sealing the wall.

[0044] The bottom plate and the middle part of the top plate are punched to form a shear groove 5. The shear grooves of the top plate and the bottom plate are hollow arc-shaped shear grooves that match each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com