A safe and low-noise steam turbine

A steam turbine and safety technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as noise hazards to the health of on-site workers, noise, and steam turbine vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

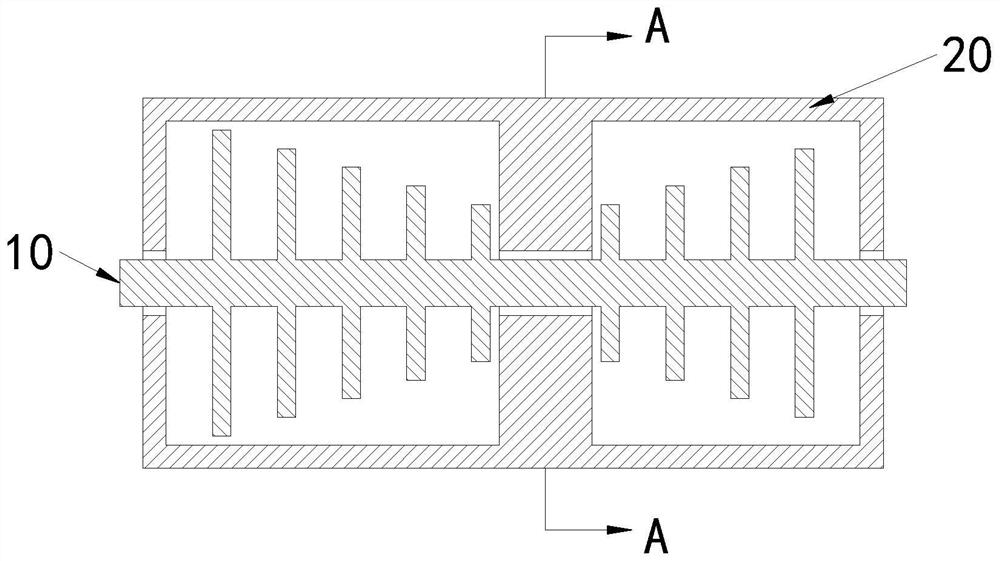

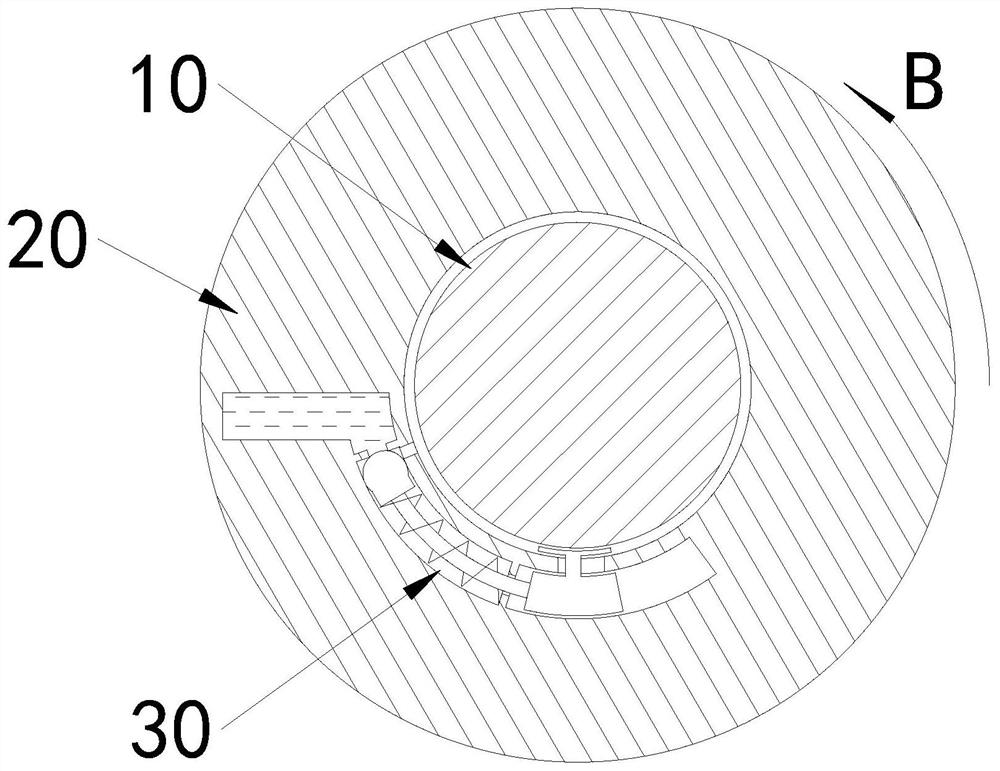

[0022] like Figure 1~2 As shown, this embodiment provides a safe and low-noise steam turbine, which includes: a rotor 10 and a cylinder 20, the rotor 10 is rotatably connected to the cylinder 20, a lubricating device 30 is arranged inside the cylinder 20, and the The rotor 10 rotates at a high speed so that when the frictional force between the air in the cylinder 20 and the cylinder 20 reaches a set value, the lubricating device 30 automatically injects lubricant into the cylinder 20 to avoid The friction force between the air in the cylinder 20 and the air in the cylinder 20 is too large, thereby reducing the noise hazard, so that the friction force between the air in the cylinder 20 and the cylinder 20 is controlled within the set value and the root cause is eliminated. Vibration causes safety hazards of parts falling off.

[0023] Tested by the inventor, the set value of the friction force is 78N.

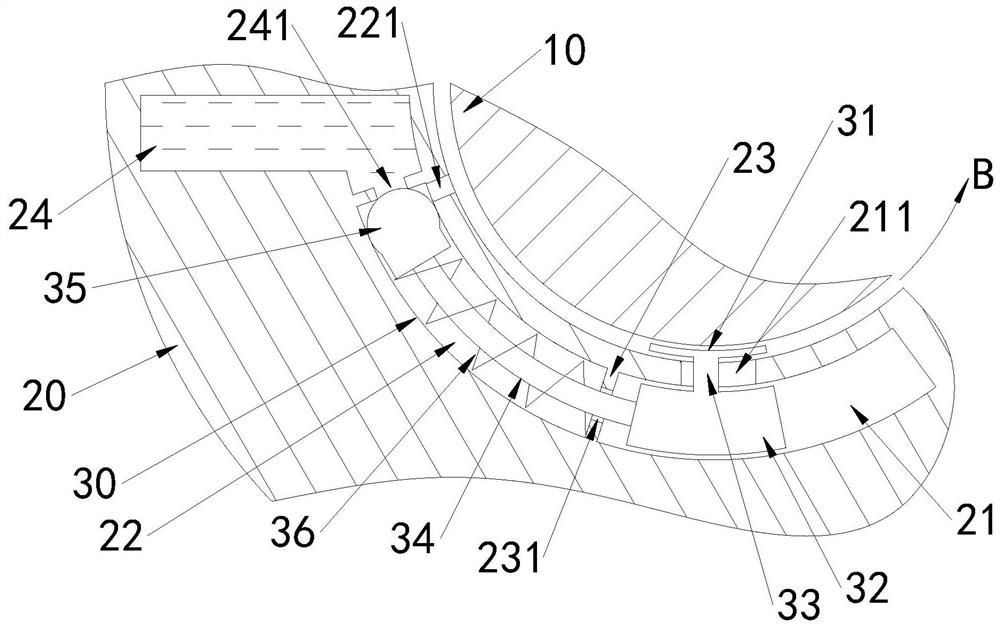

[0024] like image 3 As shown, an induction cavity 21 is opened in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com