Gas sample collecting device applied to underground coal mine

A collection device and gas sample technology, which is applied in the direction of sampling device, measuring device, sampling, etc., can solve the problems of small gas sample collection and long time of airtight sampling, and achieve improved reliability, compact airtight inspection work, and sampler device Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

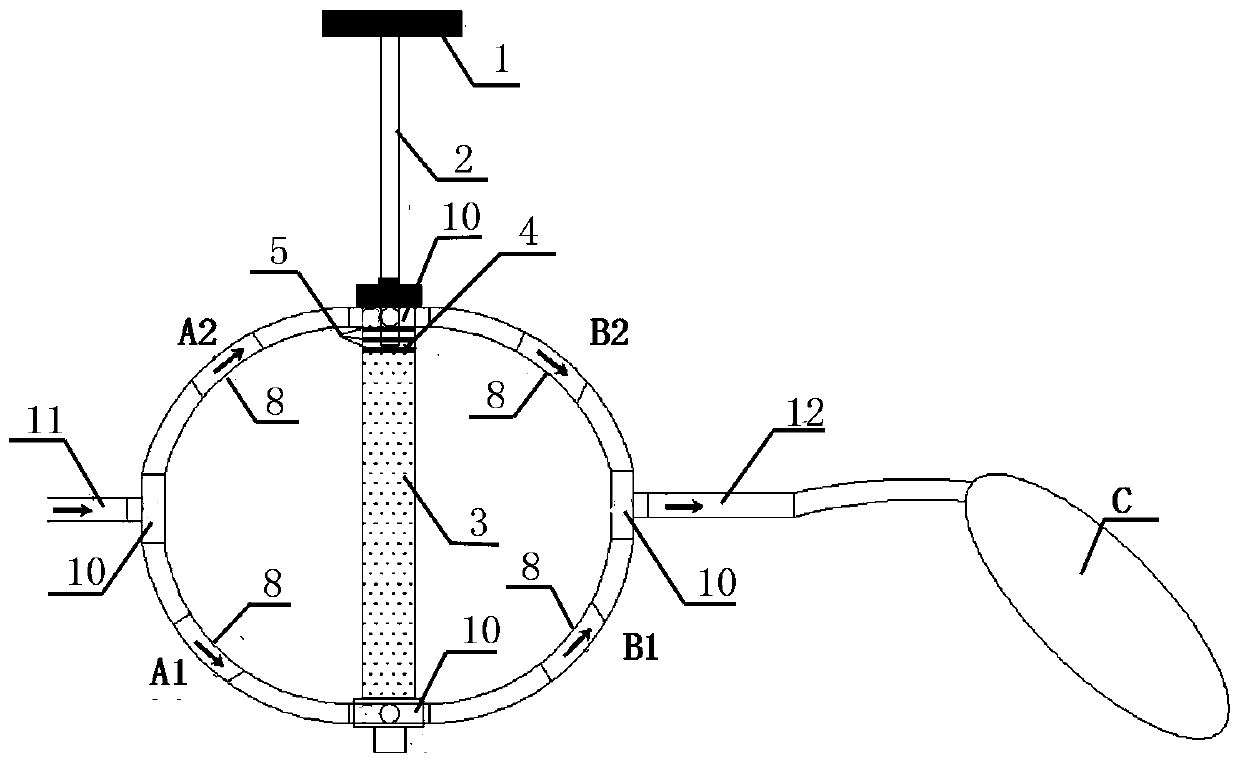

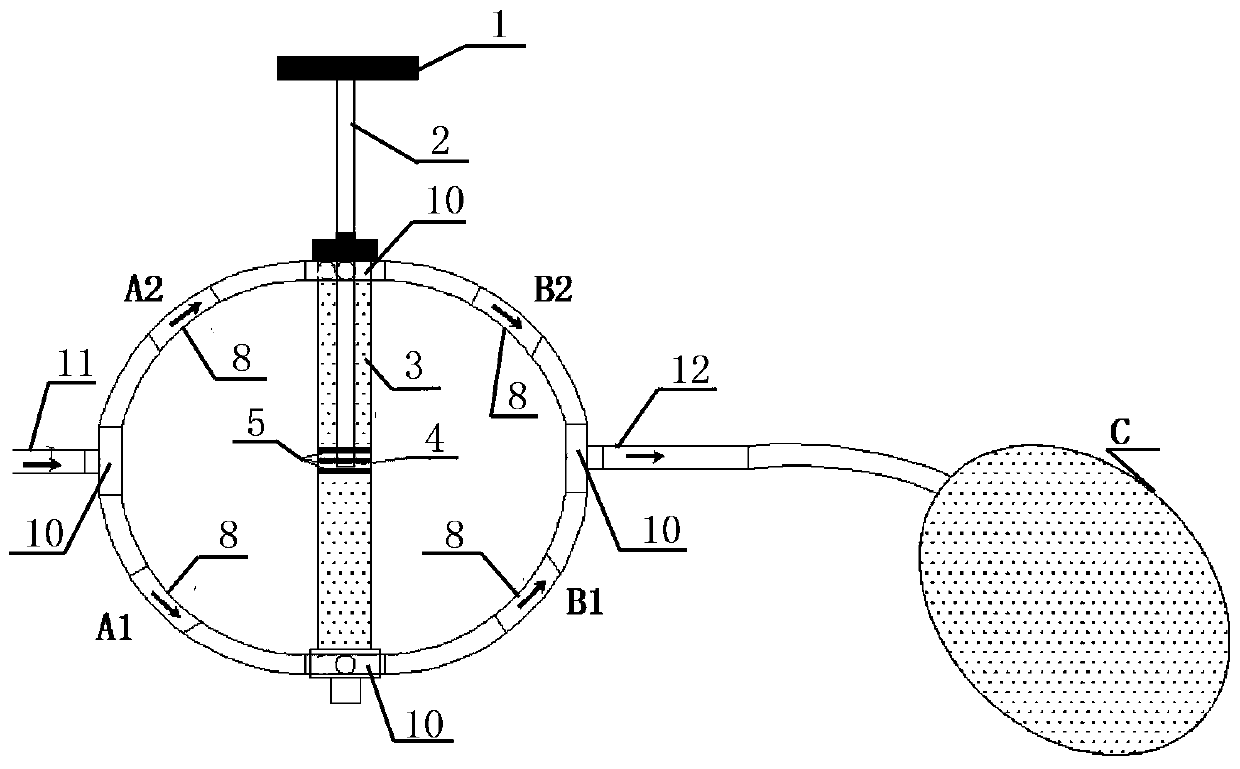

[0031] Such as figure 1 , 2 A gas sample collection device used in underground coal mines, comprising a vertical push-pull cylinder, an annular airtight channel passing through the upper and lower ends of the cylinder block 3, an air inlet pipe 11 connected to the front end of the annular airtight channel, and an annular airtight channel connected to the The exhaust pipe 12 at the rear end of the airtight passage and the sampling bag C connected to the end of the exhaust pipe 12; the inside of the cylinder block 3 communicates with the inside of the annular airtight passage; The positions on both sides and the positions on both sides of the exhaust pipe 12 are equipped with one-way check valves 8 respectively; when the reciprocating push-pull movement in the cylinder forms a negative pressure, the gas flows from the intake pipe to the exhaust pipe.

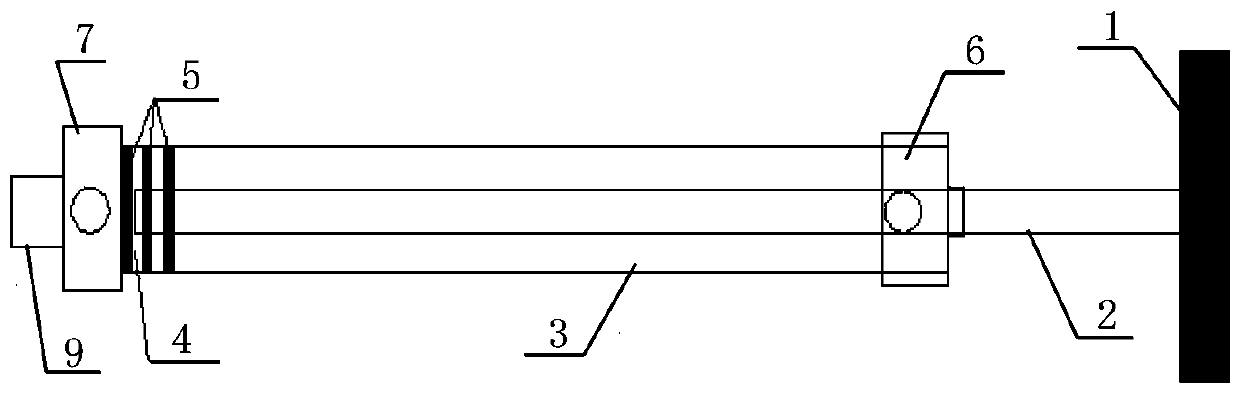

[0032] Such as image 3 , the cylinder includes a cylinder body 3, an upper end cover 7 and a lower end cover 6 connected to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com