Device for detecting rigidity of corrugated pipe

A bellows and rigidity technology, applied in the field of devices for detecting the rigidity of bellows, can solve the problems of limited detection capability and inability to detect the rigidity of bellows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

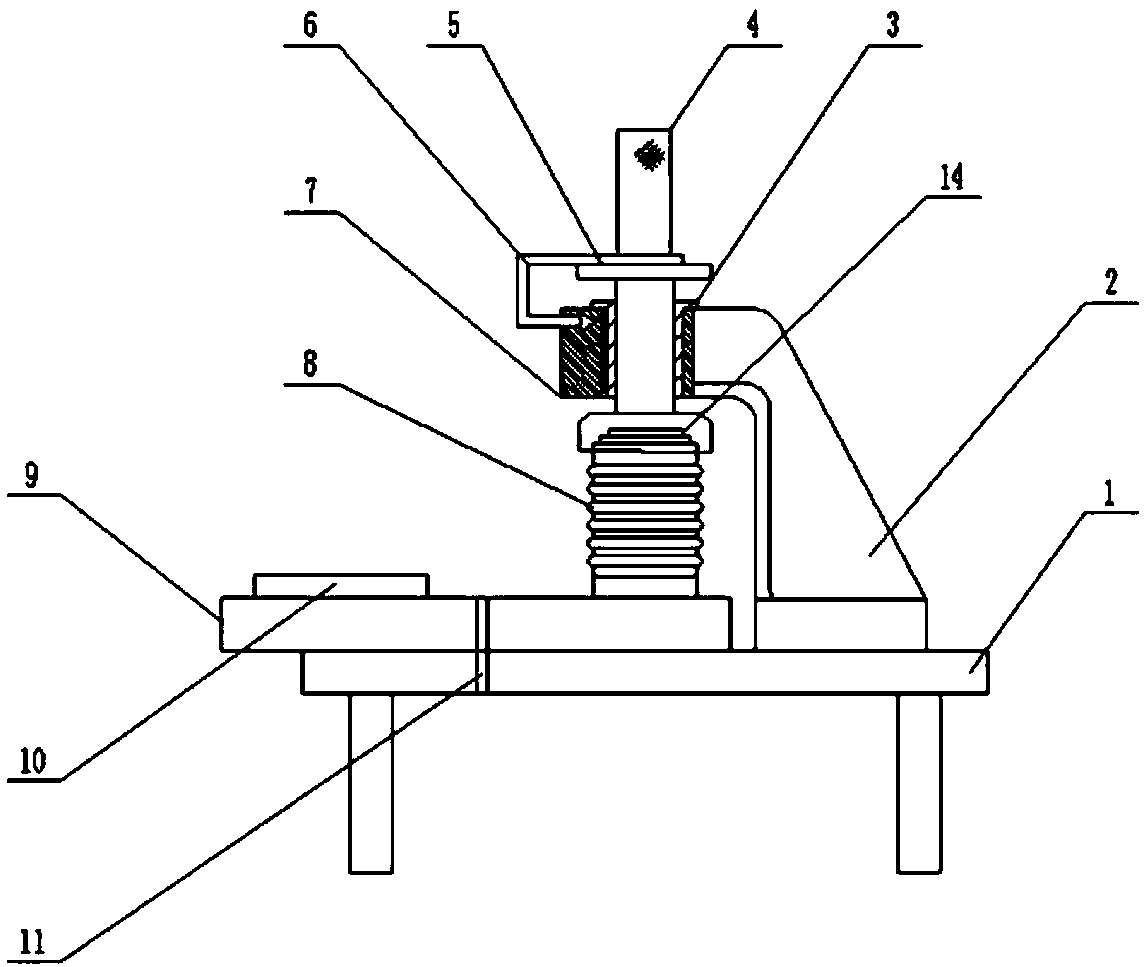

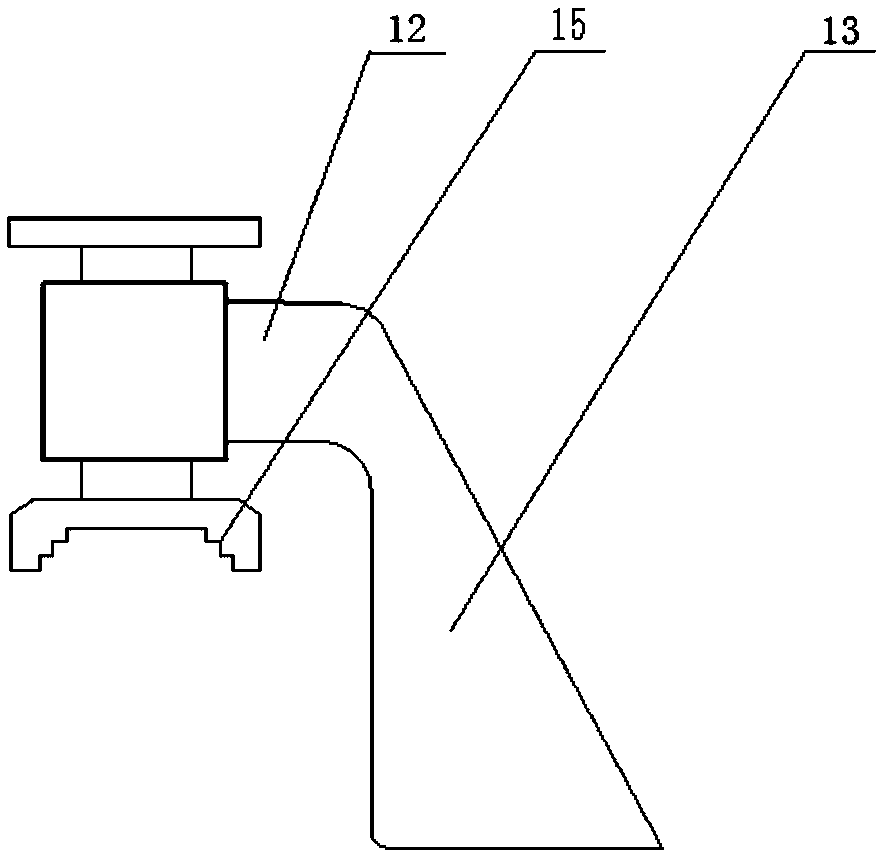

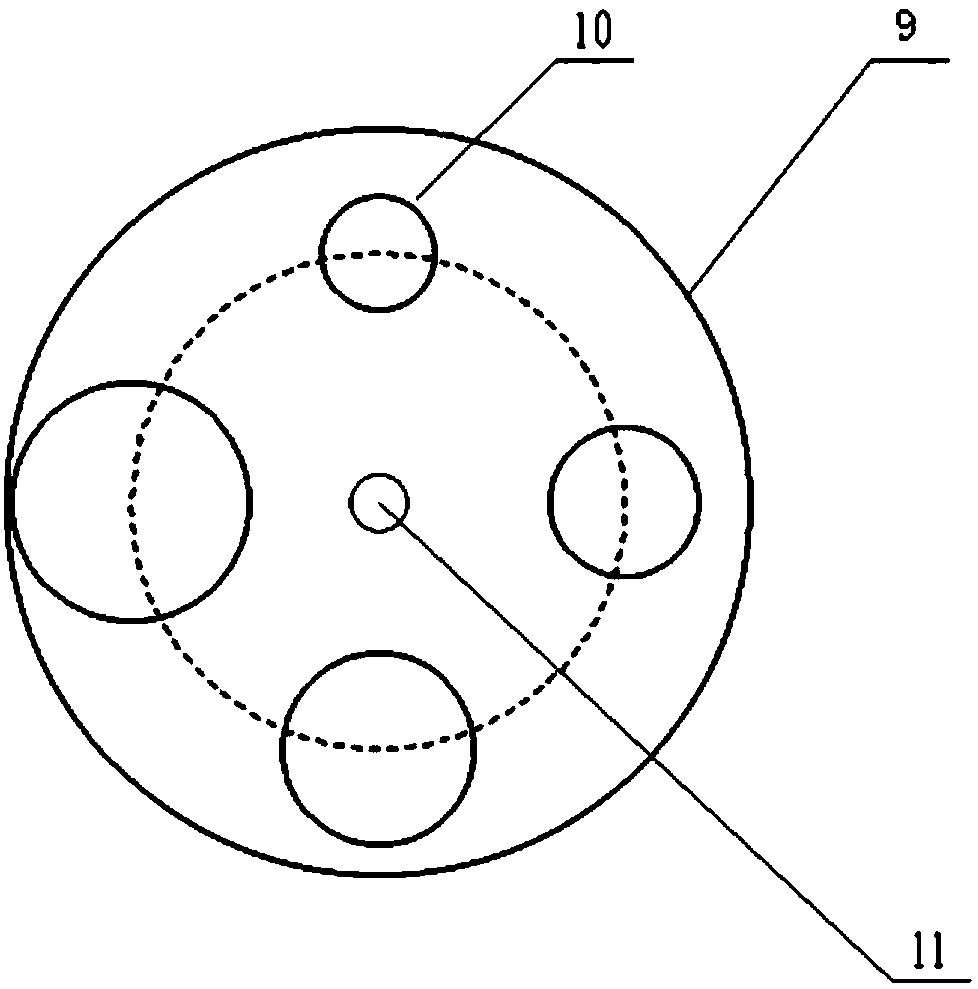

[0020] like Figure 1-3 Shown: a device for detecting the rigidity of bellows, including a platform 1, a bracket 2, a measuring cylinder 4, and a straight port switch plate 9 inside the bellows; part 12 and vertical support part 13, the horizontal end of the horizontal clamping part 12 is a hollow cylinder, and the measuring cylinder 4 is sleeved inside, and the measuring cylinder 4 is integrally connected with a synchronous pointer 6, and the horizontal clamping part 12 is fixedly installed to reflect the moving distance The dial 7 is matched with the synchronous pointer 6 for reading; the inner straight mouth switch plate 9 of the bellows is provided with a plurality of inner straight mouths 10 of different specifications for the inner straight mouth of the bellows, and is fixed on the platform 1 through the rotating shaft 11; the bottom of the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com