Rapid pre-pressing device for contact spring

A contact spring, fast technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problem of high energy in the design position of the compression spring, and achieve the effect of strong economy and simple and reliable structural adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

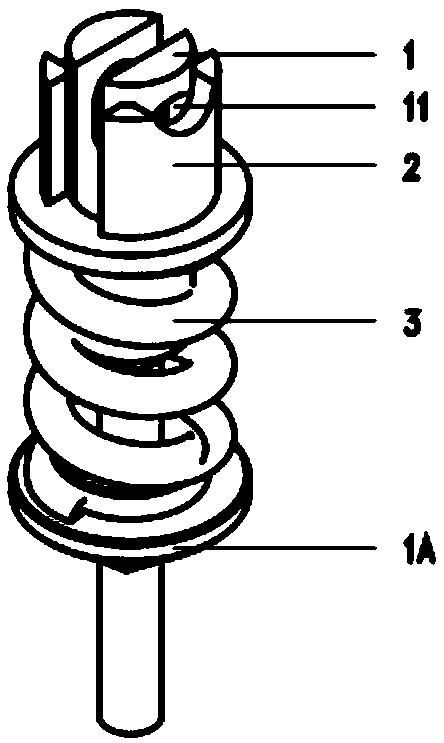

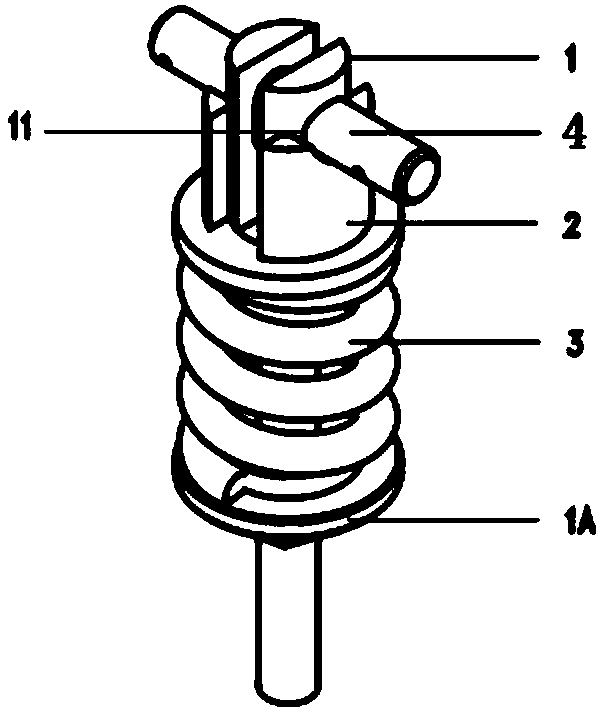

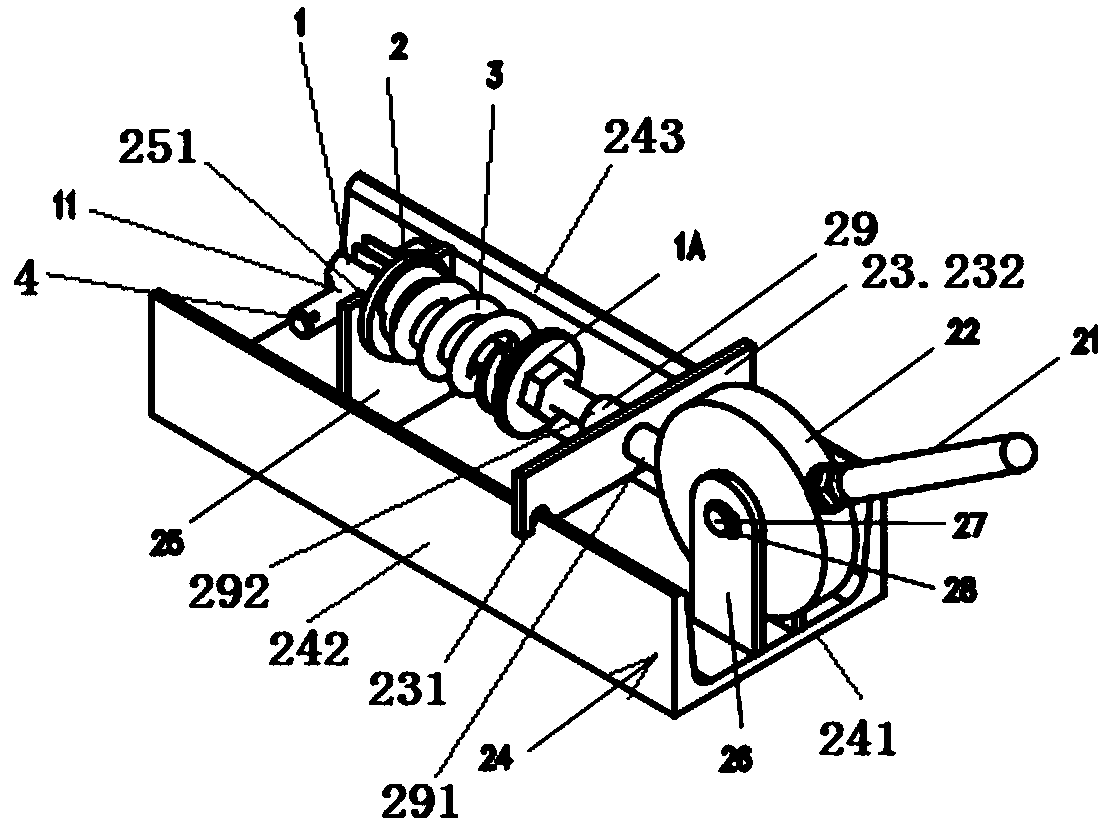

[0015] In order to make the present invention's technical means, creative features, goals and effects easy to understand, below in conjunction with specific illustrations ( figure 1 , figure 2 , image 3 ), for further elaboration.

[0016] see figure 1 and figure 2 , the contact spring assembly shown in the figure includes a guide rod 1, an upper contact spring seat 2, a compression spring 3 and a lower contact spring seat 1A, the lower contact spring seat 1A is fixed on the guide rod 1, and the upper contact spring The seat 2 and the compression spring 3 are sleeved on the guide rod 1, and the compression spring 3 is located between the upper contact spring seat 2 and the lower contact spring seat 1A. After preloading, the cylindrical pin hole 11 of the guide rod 1 exposes the upper contact spring seat 2, and a cylindrical pin 4 passes through the cylindrical pin hole 11 to force the upper contact spring seat 2 to move in the direction of the downward contact spring se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com