Assembly method of chassis of heavy oceaneering crane of deepwater pipe-lay crane vessel

A technology for marine engineering and deep-water pipe laying, which is applied in ship parts, ship accessories, ship construction, etc., can solve problems such as no reference process, and achieve the effect of good process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

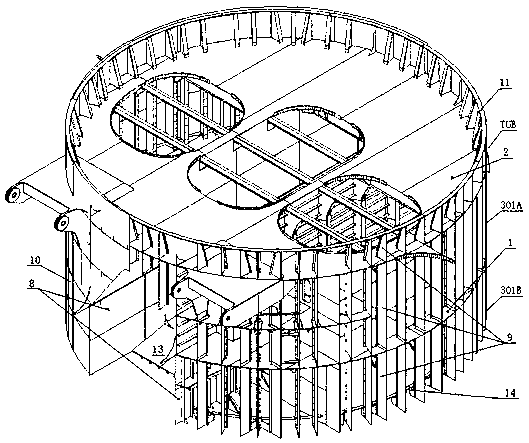

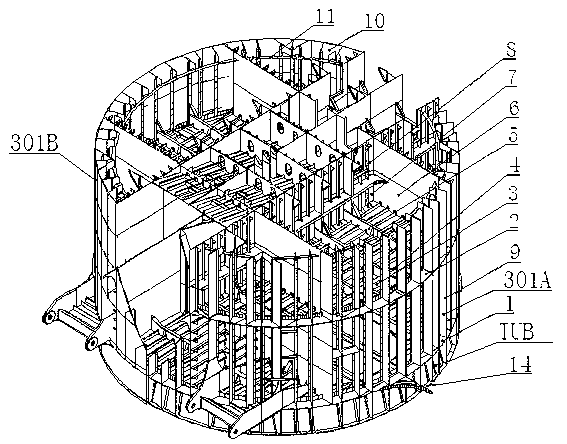

[0019] see Figure 1 to Figure 5 , the heavy-duty ocean engineering crane base proposed by the present invention is located at the stern of the hull, and its own weight is 4000 tons. In the fixed stern mode, the turning radius is 43m and the lifting capacity is 4000 tons; in the full turning mode, the turning radius is 33m and the lifting capacity is 3500 tons.

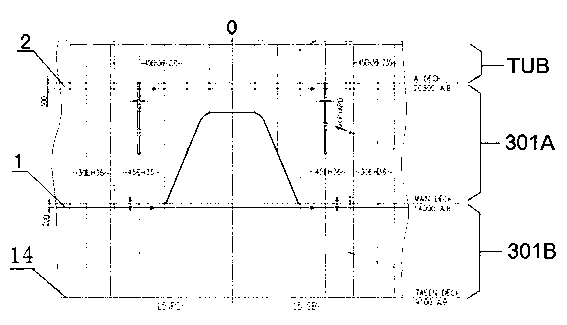

[0020] The proposed crane base is a cylindrical structure with a diameter of 24.3m and a height of 13.40m. The upper part of the cylinder is a steel plate with a wall thickness of 45mm and the material is EH36-Z35, and the lower part is a steel plate with a thickness of 30mm and 45mm and the material is EH36. The bottom of the cylinder is welded on the platform deck 14 which is 9100mm away from the baseline, and its upper part still has a 2.2m high cylinder wall on the A deck 2.

[0021] For specific base structure, see figure 1 and figure 2 : taking the main deck 1 as the base surface, laying a deck bottom plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com