Flexible display panel and display device

A flexible display and panel technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems affecting signal transmission, cracks, fractures, etc., and achieve the effect of improving stress concentration and reducing bending stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

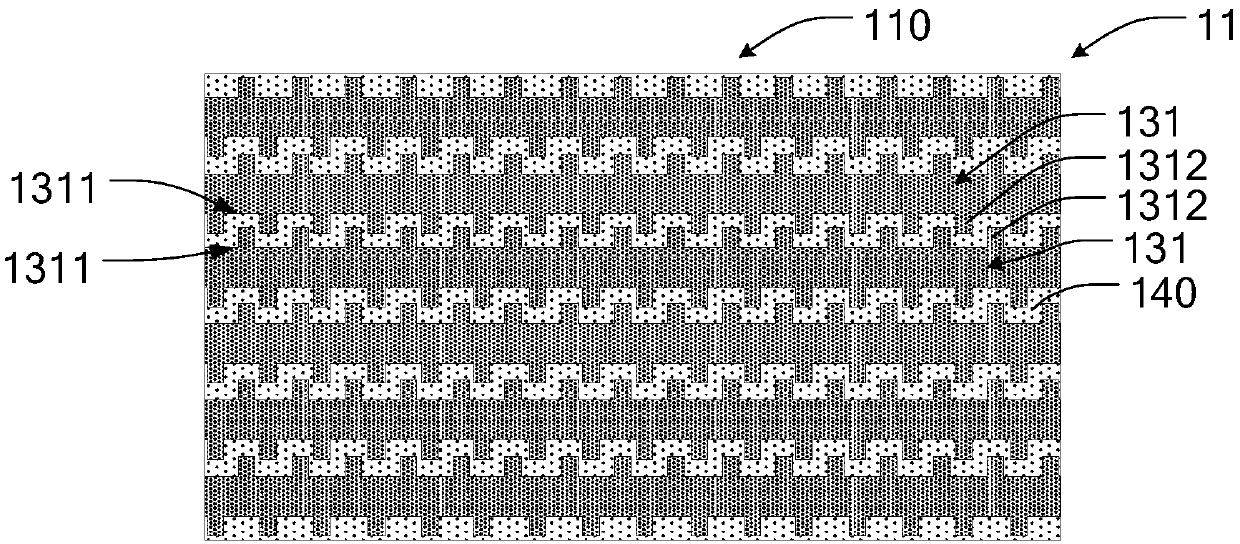

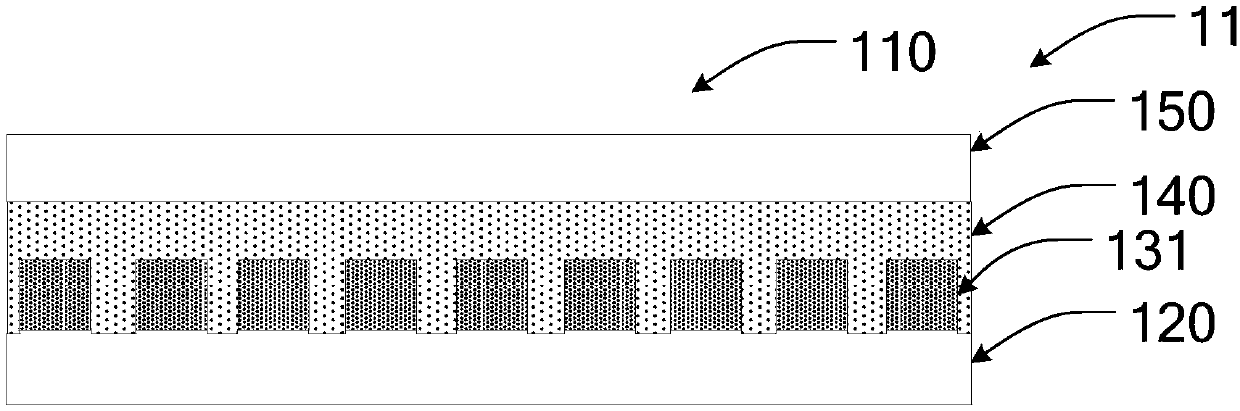

[0032] Such as figure 1 As shown, in this embodiment, the flexible display panel 11 of the present invention has a bending area 101 and a metal layer correspondingly distributed in the bending area 101. The metal layer has several metal traces 131. Generally, , the metal traces 131 are straight traces, and the metal traces 131 are parallel to each other.

[0033] In order to reduce the stress concentration phenomenon of the metal wires 131 in the bending area 101 during bending, and prevent cracks and peeling of the metal wires 131 during bending, resulting in performance degradation, failure, etc., each At least one side of the metal trace 131 has a protrusion 1312 . In this embodiment, both sides of the metal trace 131 are provided with protrusions 1312 , and the protrusions 1312 on both sides of each metal trace 131 are arranged alternately. On the metal trace 131 , the protrusions 1312 on each side are arranged equidistantly. The shape of the protrusion 1312 is at least...

Embodiment 2

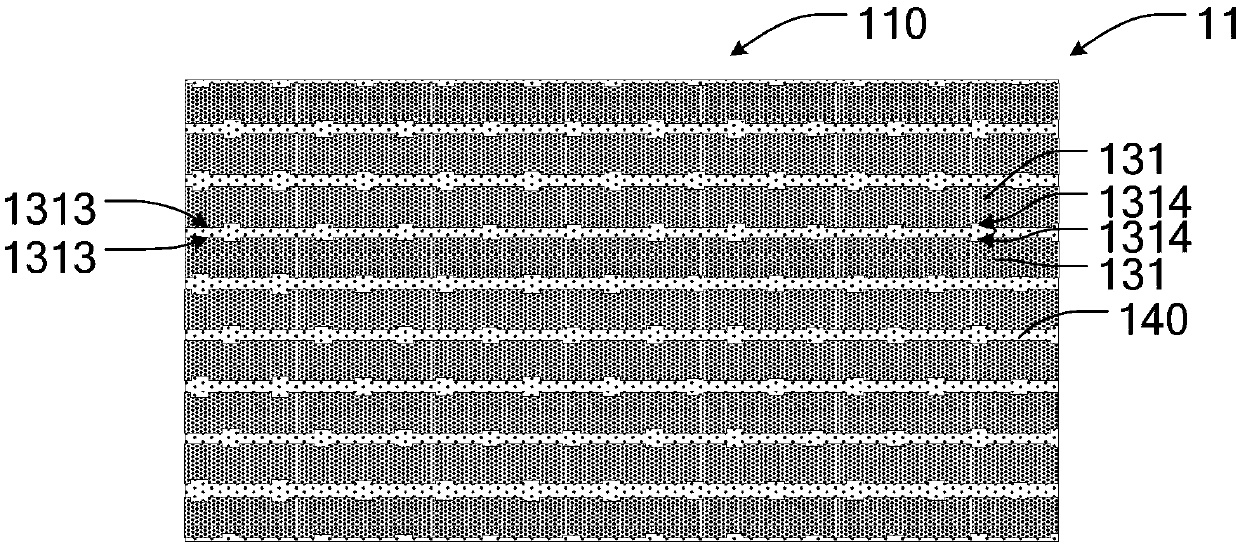

[0038] Such as image 3 As shown, in this embodiment, the flexible display panel 11 of the present invention has a bending area 101 and a metal layer correspondingly distributed in the bending area 101. The metal layer has several metal traces 131. Generally, , the metal traces 131 are straight traces, and the metal traces 131 are parallel to each other.

[0039]In order to reduce the stress concentration phenomenon of the metal wires 131 in the bending area 101 during bending, and prevent cracks and peeling of the metal wires 131 during bending, resulting in performance degradation, failure, etc., each At least one side of the metal trace 131 has a groove 1314 . In this embodiment, both sides of the metal traces 131 are provided with grooves 1314 , and the grooves 1314 on both sides of each metal trace 131 are alternately arranged. On the metal traces 131 , the grooves 1314 on each side are arranged equidistantly.

[0040] In order to optimize the spatial layout of the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com