Linear high-power-factor driving circuit

A high power factor, drive circuit technology, applied in the direction of electric light source, electrical components, electroluminescent light source, etc., can solve the problem that the ripple-free drive circuit is difficult to meet the high power factor requirements, and achieve high PFC and ripple-free Contradictions and conflicts of waves, simple and convenient adjustment, and the effect of improving power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

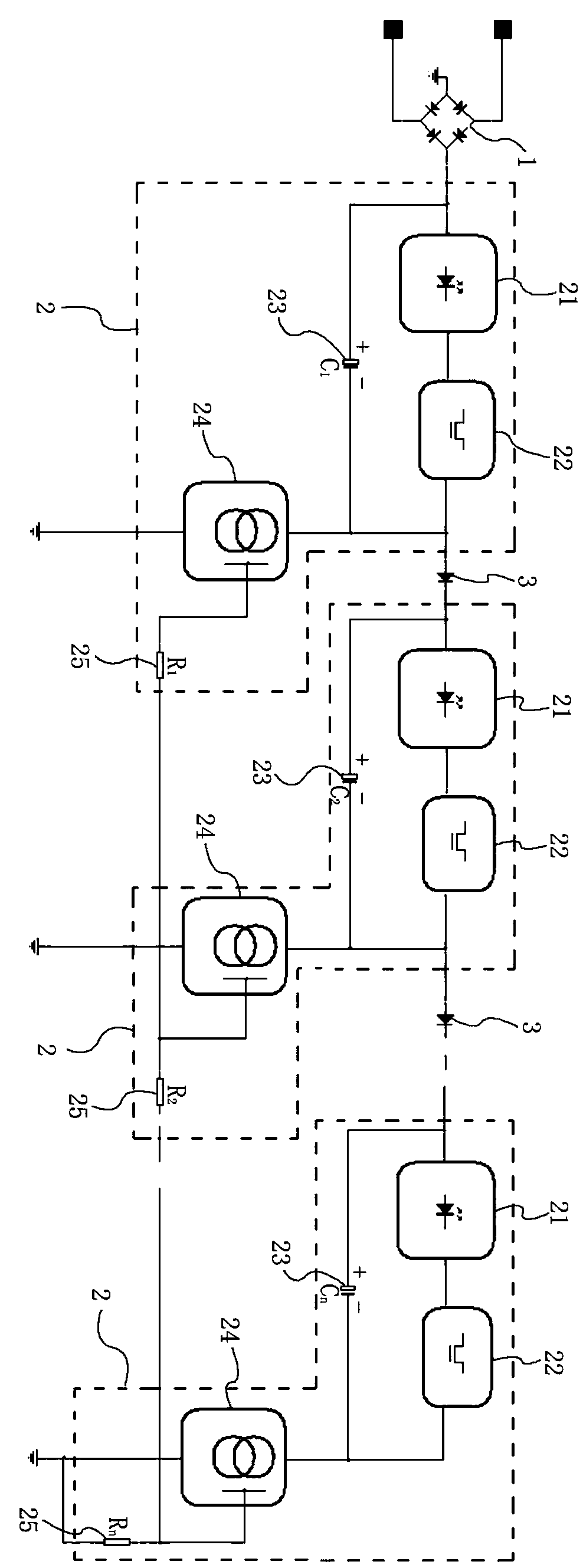

[0040] Reference attached figure 1 to attach image 3 , a linear high power factor drive circuit in this embodiment includes a power supply, a rectifier 1 connected to the power supply at the input end, a plurality of drive circuit units 2 connected in sequence, and the first drive circuit unit 2 ( figure 1 The leftmost driving circuit unit) is connected to the output terminal of the rectifier 1, assuming that there are N driving circuit units 2 in this embodiment, and the distance between the Nth driving circuit unit 2 figure 1 Rectifier 1 in the furthest ( figure 1 The rightmost drive circuit unit in the ).

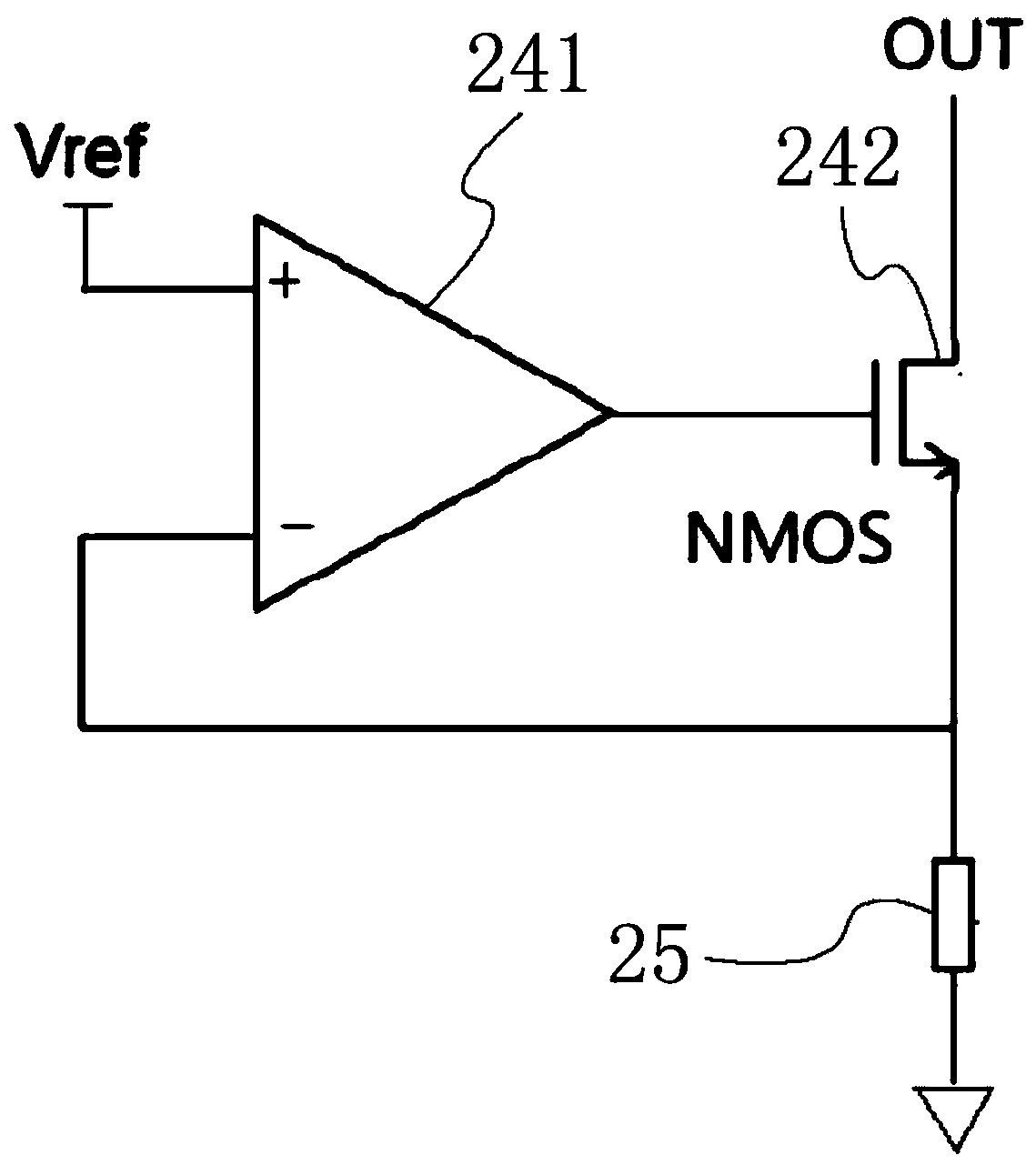

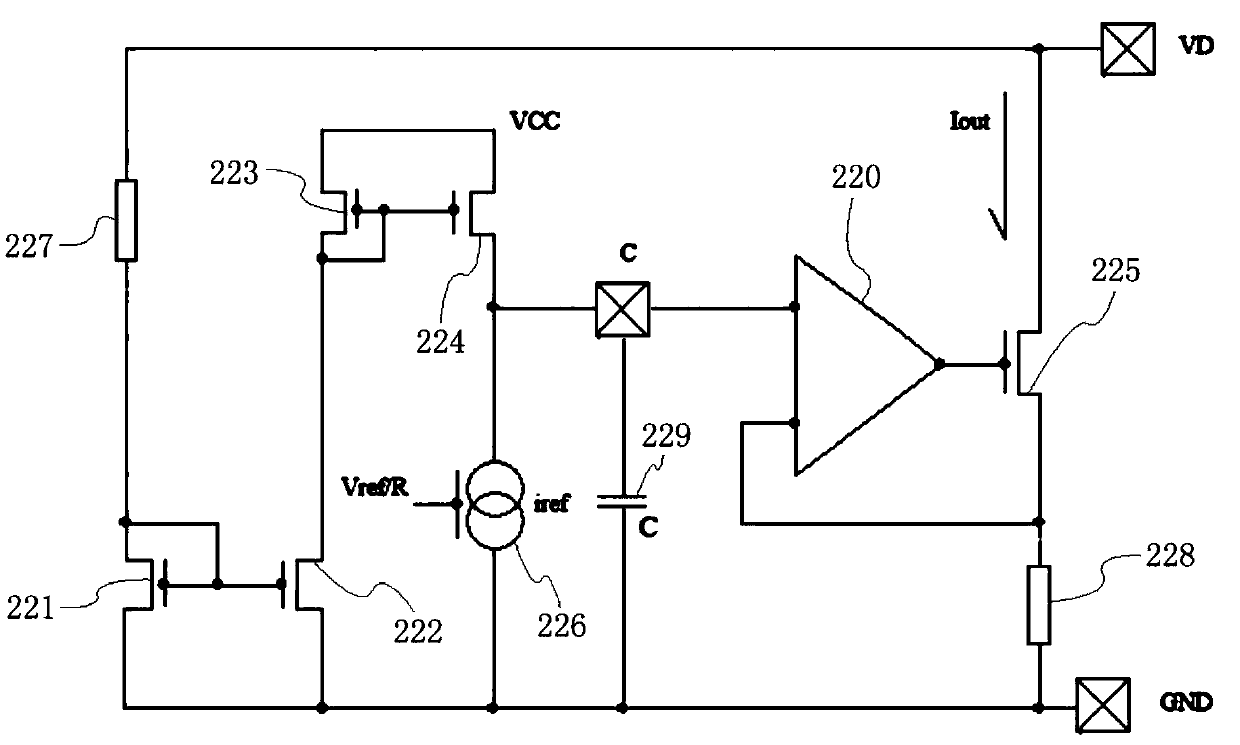

[0041] Such as figure 1 As shown, each of the drive circuit units 2 includes an LED load 21 (one or more LED lamps connected in series), an electronic filter 22, an electrolytic capacitor 23, a current regulator subsection circuit unit 24, and a current detection resistor 25. The LED load 21 and the electronic filter 22 are connected in series to form a first branch...

Embodiment 2

[0058] Reference attached Figure 4 , the difference between the linear high power factor drive circuit in this embodiment and the first embodiment is only that:

[0059] In this embodiment, the floating working mode is adopted. Among the plurality of driving circuit units 2, in each driving single-circuit unit except the last one, the ground terminal of the segment circuit unit 24 of the constant current device and the current detecting resistor 25 at the other end ( figure 1 with Figure 4 The right end as shown) is connected; in the last drive circuit unit 2, the ground terminal of the current regulator section circuit unit 24 is connected to the other end of the current detection resistor 25 and then grounded.

[0060] The isolation segmenter 3 in the present embodiment adopts the NPN triode, and the collector of the triode is connected with the junction of the electronic filter 22 and the segment circuit unit 24 of the constant current device in the previous driving cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com