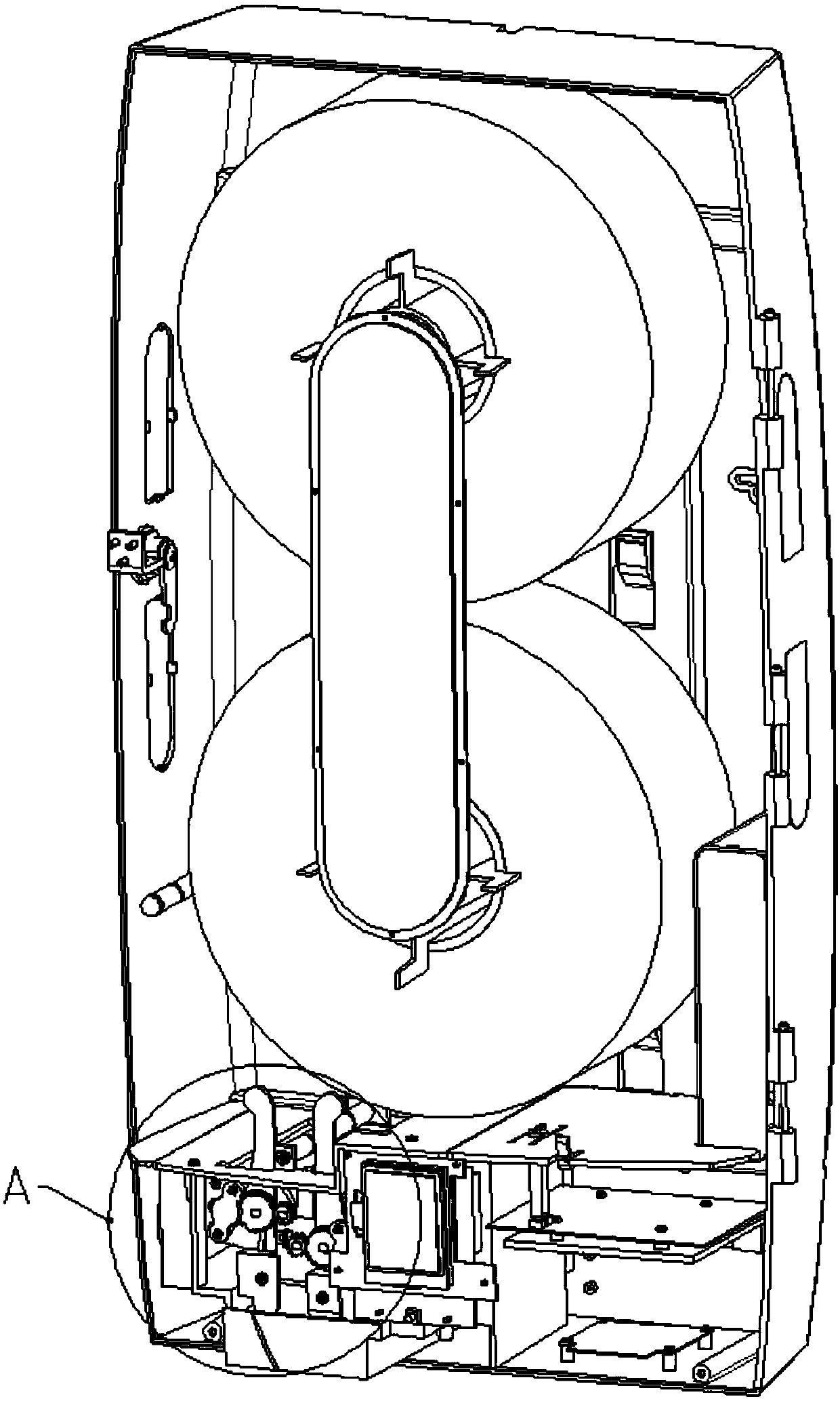

Intelligent tissue outlet machine core

A technology of paper output machine and core, which can be applied in the direction of home appliances, etc., can solve the problems of paper towel waste and inconvenient use, and achieve the effect of not easy to slip, reliable paper towel output, and not easy to be damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

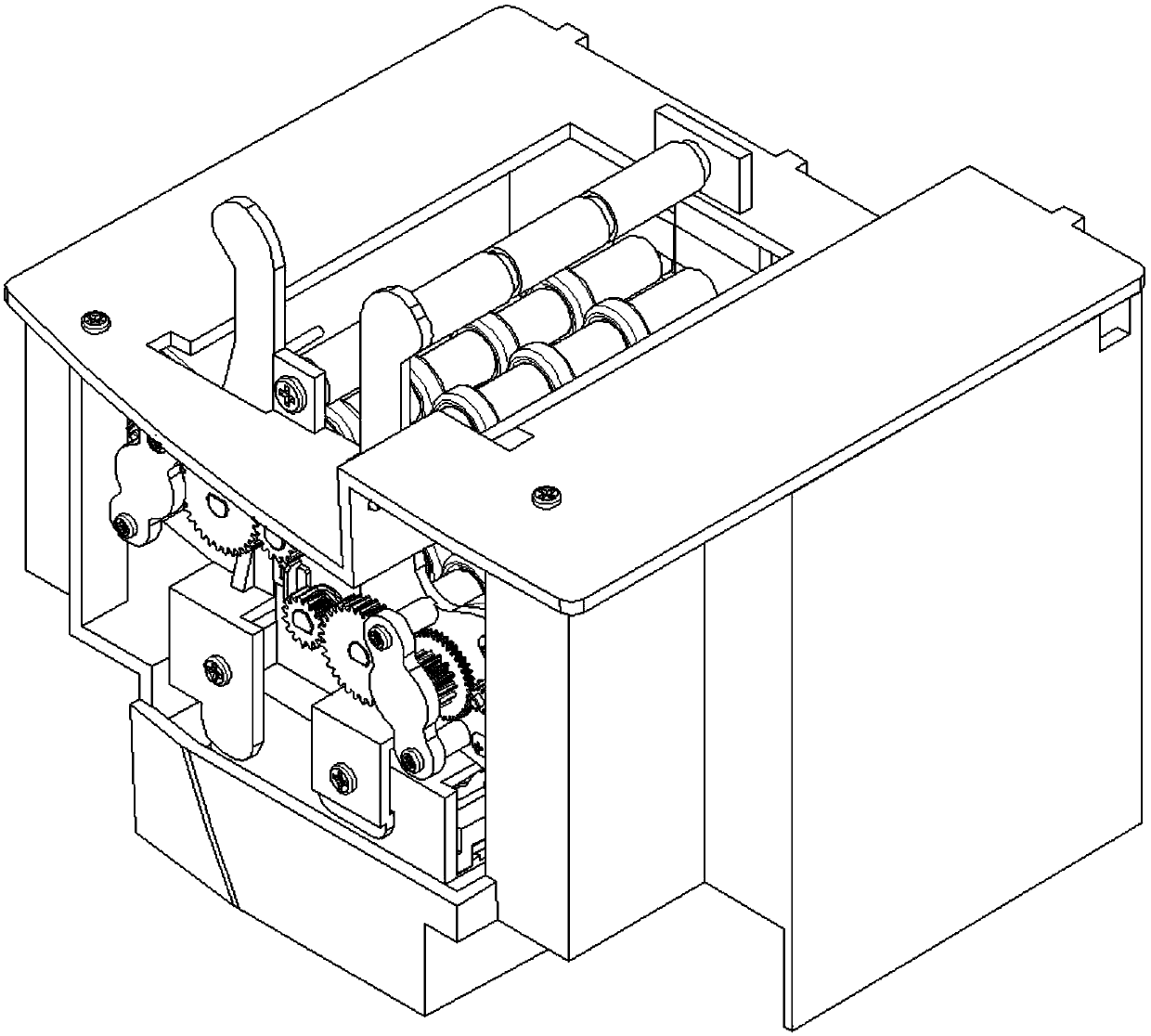

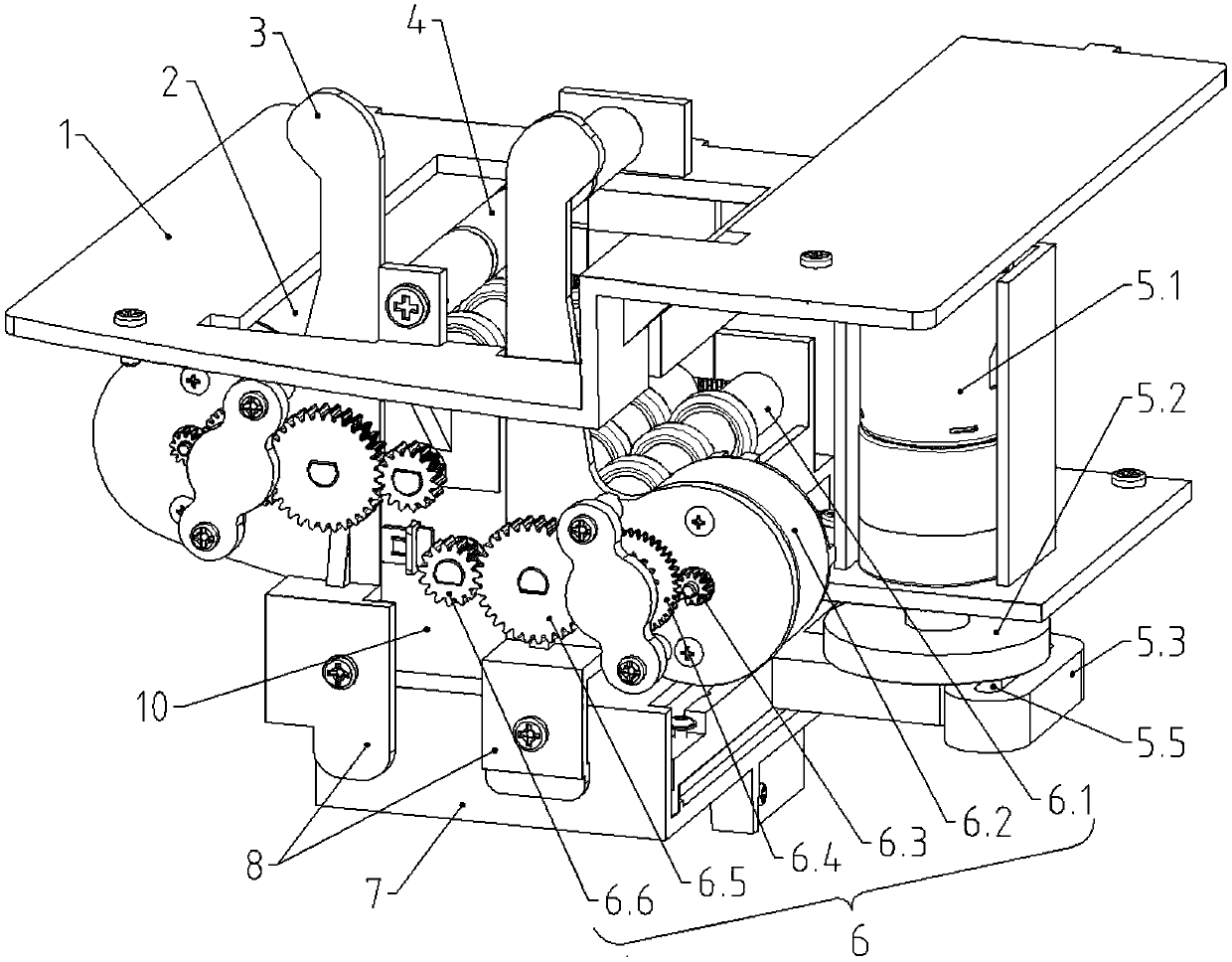

Embodiment 1

[0037]An intelligent paper output machine core, including a shell composed of a top plate 1, a base 7, and two side plates 10 on the front and rear sides, the top plate 1 and the base 7 are respectively provided with a paper inlet 2 and a paper outlet 11 A paper feeding mechanism 6 and a paper cutting mechanism 9 are sequentially arranged between the paper inlet 2 and the paper outlet 11 in the casing, and a power mechanism 5 for driving the paper cutting mechanism 9 is arranged on one side of the paper cutting mechanism 9. The paper feeding mechanism 6 includes two rollers 6.1 arranged side by side. The two rollers 6.1 are erected between the two side plates 10. The ends of the two rollers 6.1 are respectively provided with a driven gear a6.5 and a driven gear a6.5. The driving gear b6.6, the side plate 10 is provided with an intermediate gear 6.4 and a paper feeding motor 6.2 with a driving gear 6.3 at the output end, the driving gear 6.3, the intermediate gear 6.4, the drive...

Embodiment 2

[0042] This embodiment improves on the basis of Embodiment 1:

[0043] The two rollers 6.1 are provided with a number of evenly distributed rubber rings 14 and the circumferential surfaces of the rubber rings 14 on the two rollers 6.1 are in contact with each other. The rollers 6.1 are provided with circumferential holes for installing the rubber rings 14. Install ring groove 15. The cross-section of the rubber ring 14 can be circular, elliptical, waist-shaped and rectangular.

[0044] The advantages of the above improvements are: the elastic rubber ring is used to contact the paper towel to transport the paper towel, and the elasticity of the rubber ring is used to increase the friction between the rubber ring and the paper towel, making the paper towel output more reliable, not easy to slip, and elastic The material of the rubber ring itself can also protect the rolled paper towels from being damaged. The installation of the ring groove is convenient for the positioning and...

Embodiment 3

[0046] This embodiment improves on the basis of Embodiment 1:

[0047] The paper cutting mechanism 9 includes a knife rest 9.1 horizontally arranged on the right side above the paper outlet 11. The knife rest 9.1 is connected and matched with the power mechanism 5. A horizontal cutting knife 9.2 is fixed on the lower surface of the knife rest 9.1. A fixed cutting block 12 that cooperates with the cutter 9.2 is provided, and two chute 9.4 are arranged on the front and rear sides of the paper outlet 11 on the base 7, and the both sides of the knife rest 9.1 cooperate with the chute 9.4 through the slide block 9.3.

[0048] Working principle: the paper cutting mechanism 9 operates under the action of the power mechanism 5. Specifically, the power mechanism 5 drives the knife rest 9.1 to move horizontally back and forth. When the roll paper is output through the paper outlet 11, the power mechanism 5 drives the knife rest 9.1 Move to the left as a whole with the cutter 9.2, the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com