Glass processing equipment

A processing equipment, glass technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problem that the gripping device is easy to damage the glass handle and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

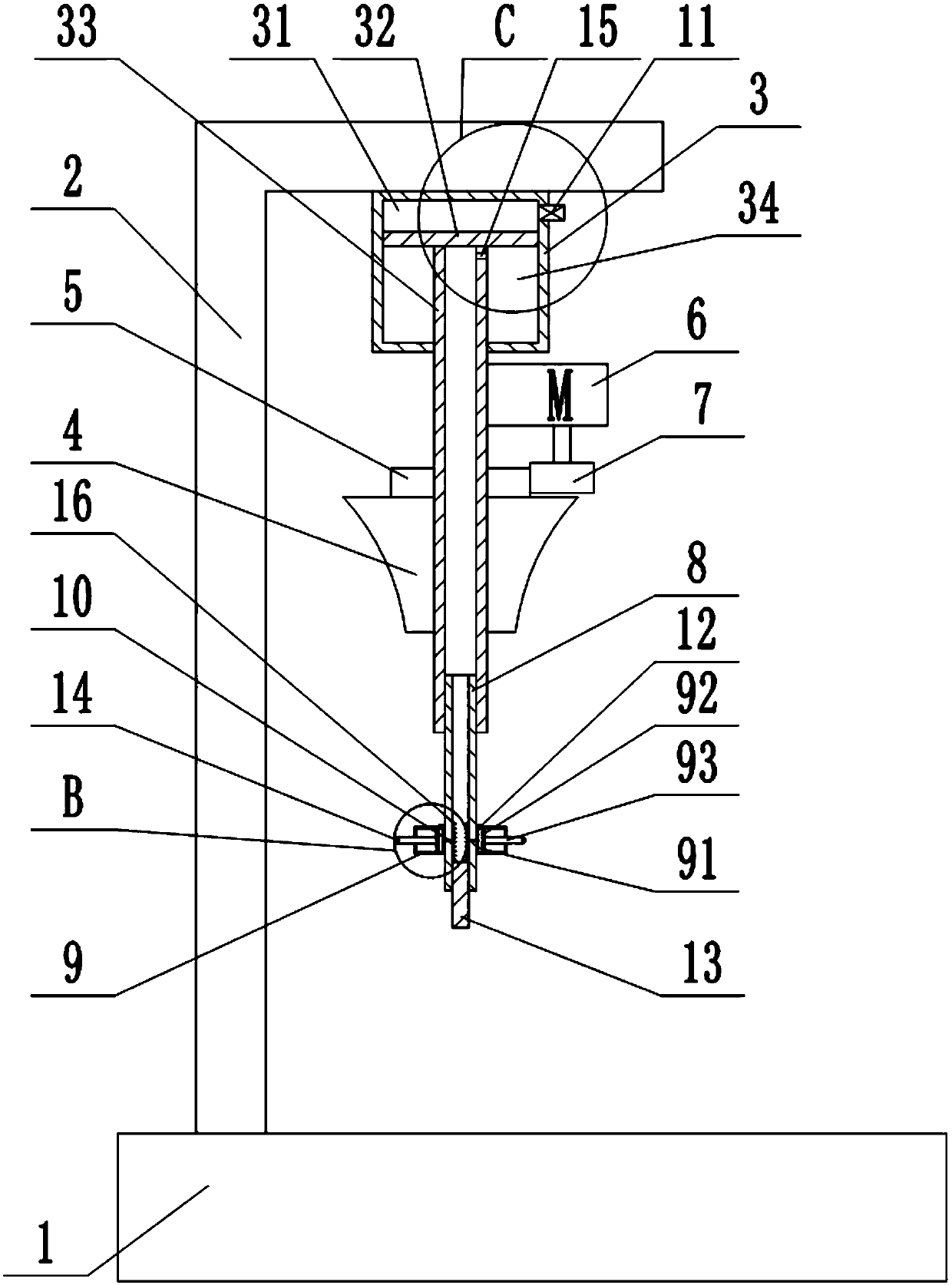

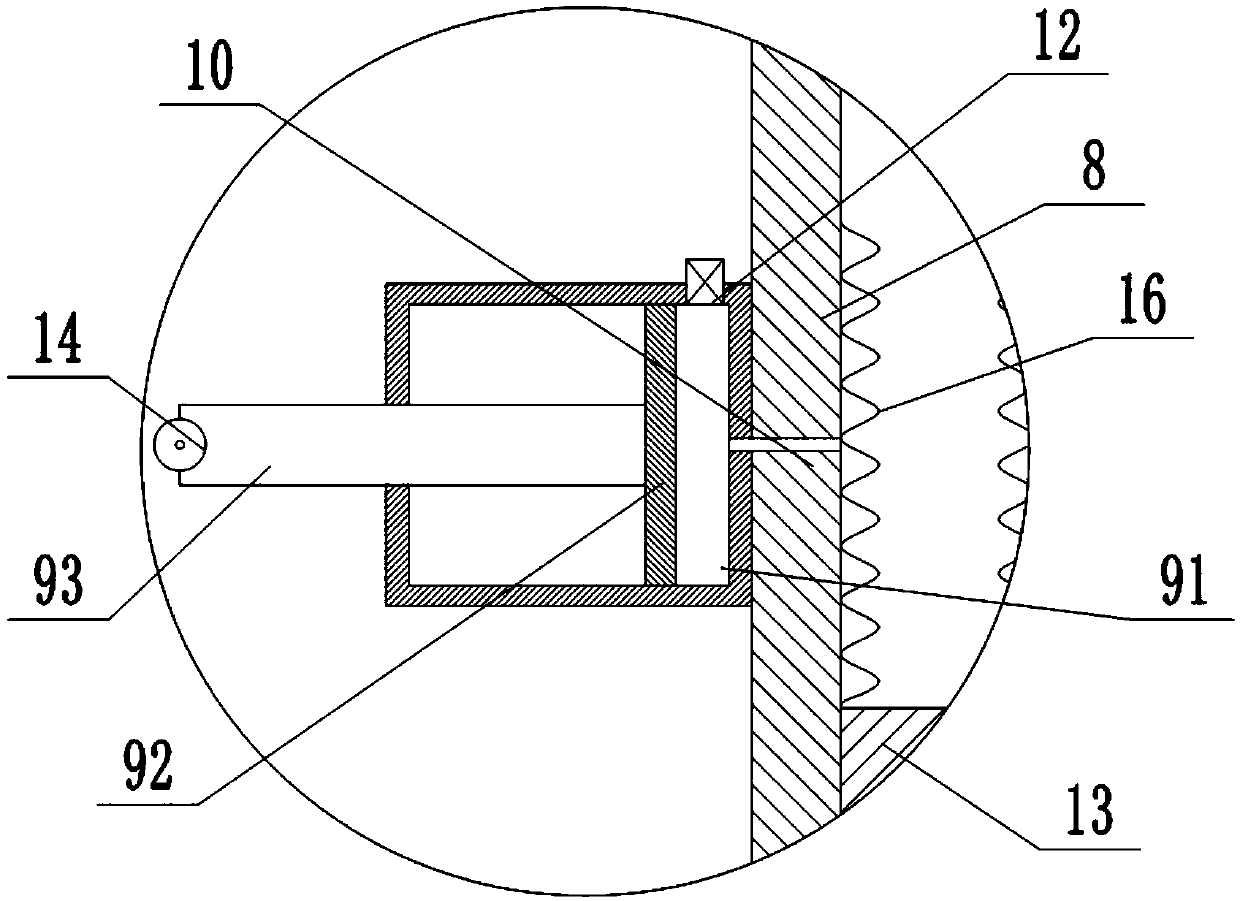

[0023] The following is further described in detail through specific implementation methods:

[0024] The reference signs in the drawings of the description include: processing table 1, bracket 2, driving cylinder 3, grinding block 4, first gear 5, driving motor 6, driving gear 7, extrusion rod 8, positioning cylinder 9, pipeline 10, The first overflow valve 11, the second overflow valve 12, the positioning rod 13, the rubber ball 14, the through hole 15, the spring 16, the first rodless cavity 31, the first piston plate 32, the first piston rod 33, the first There is a rod chamber 34 , a second rodless chamber 91 , a second piston plate 92 , and a second piston rod 93 .

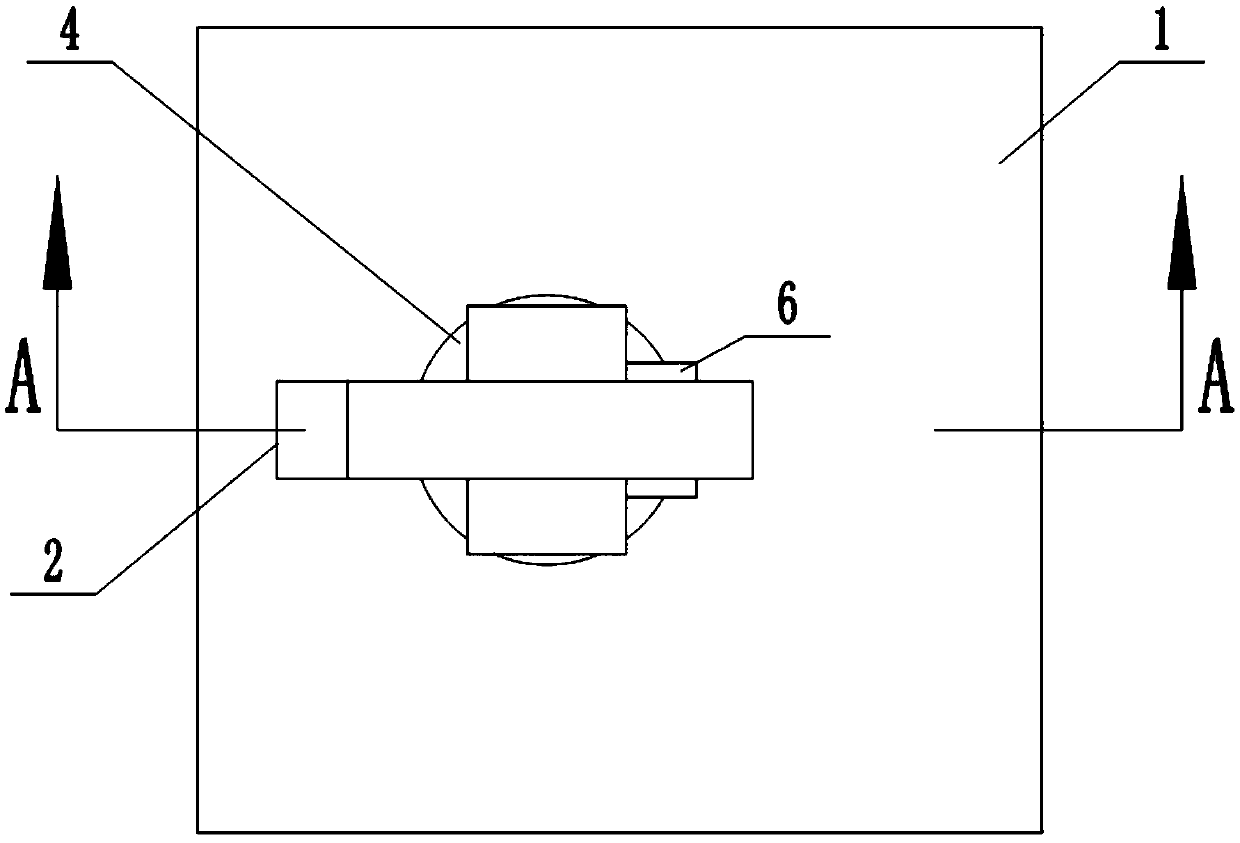

[0025] The embodiment is basically as attached figure 1 , figure 2 and Figure 4 Shown:

[0026] A glass processing equipment, comprising a processing table 1, on which an L-shaped support 2 is welded, on which a bolt is connected to a vertically downward driving cylinder 3, and the piston rod of the dr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap