Tool for accurately disassembling and assembling components on rotating shaft and using method thereof

A technology for rotating shafts and components, which is applied in the field of tooling for precise disassembly and assembly of components on the rotating shaft. It can solve problems such as difficult precise assembly, loose new standard parts, and damage to the rotating shaft. It achieves high work efficiency, easy operation, and improved work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

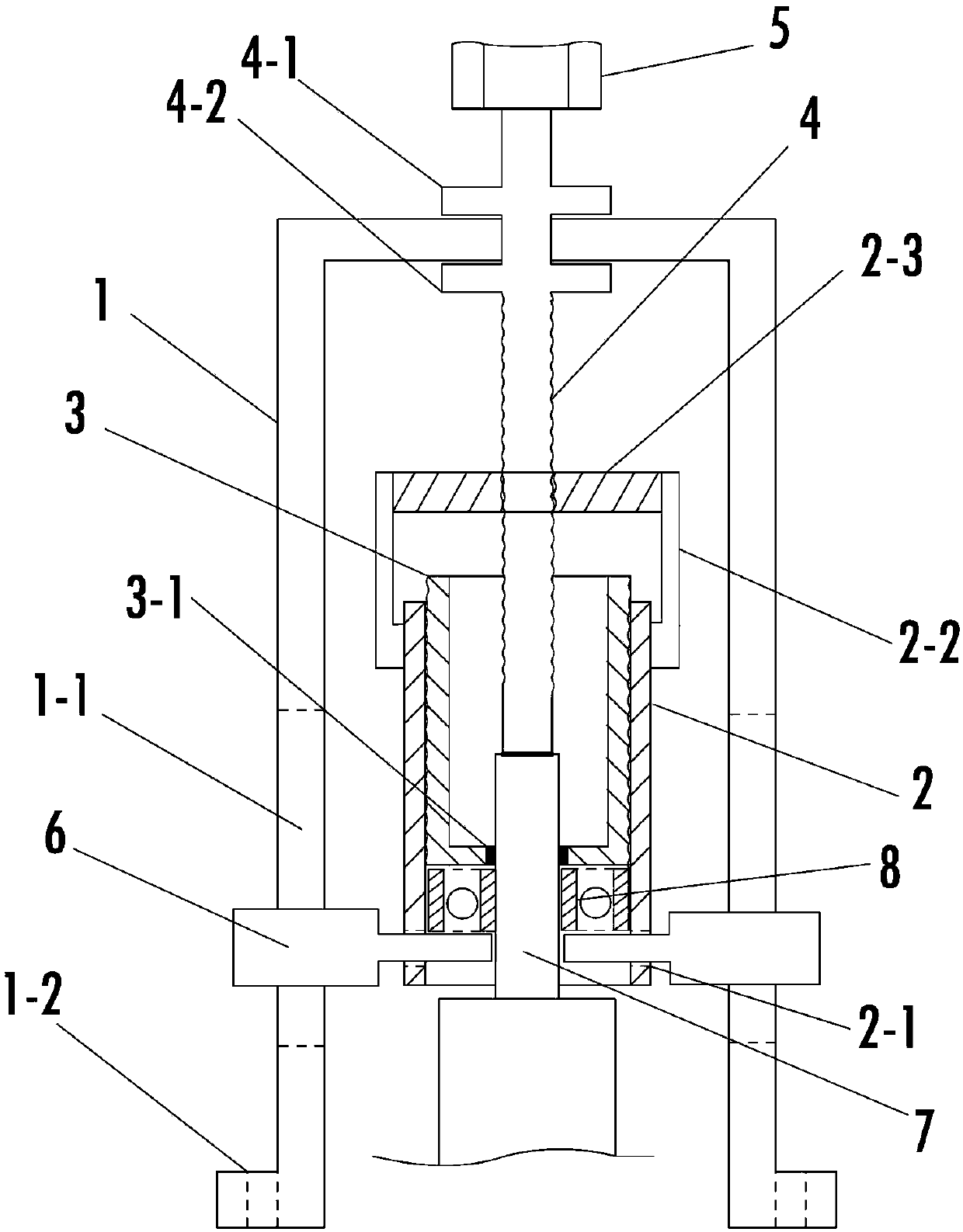

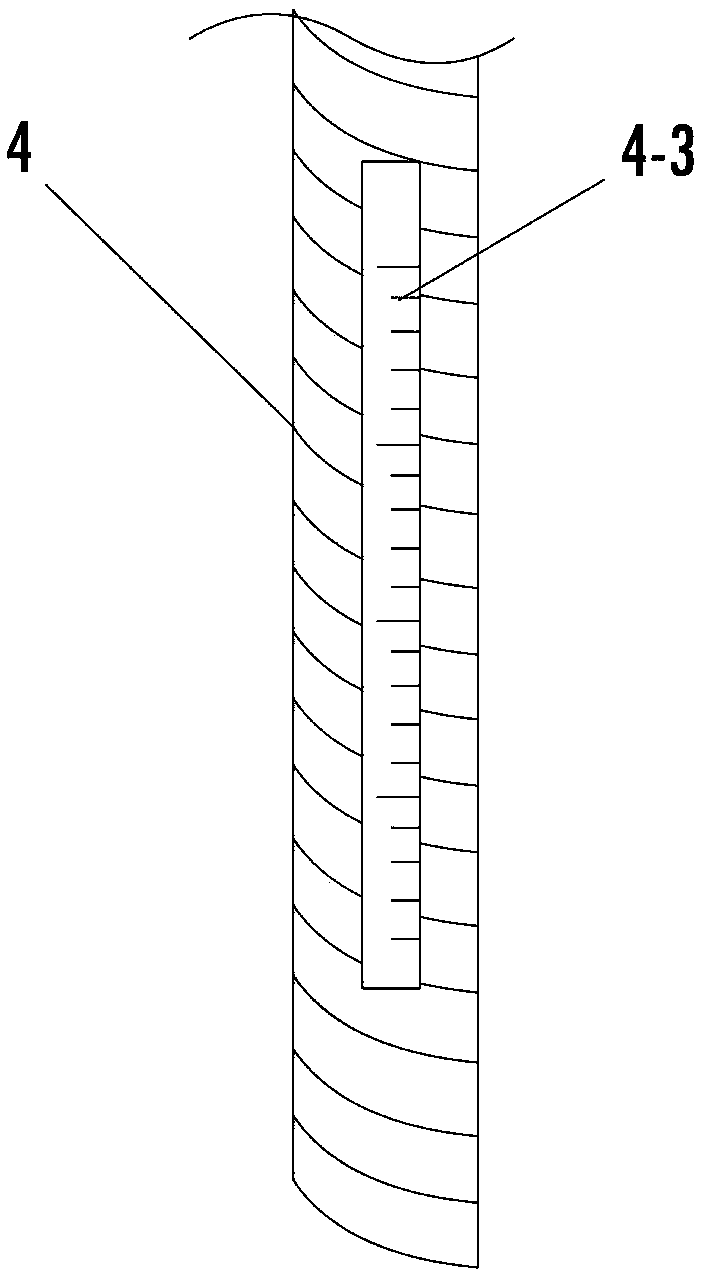

[0027] Such as Figure 1~2 As shown, a tool for precise disassembly and assembly of components on a rotating shaft includes an outer bracket 1, an inner support sleeve 2, a central rotating shaft 4; the inner support sleeve 2 is in a straight tubular shape, and its inner cavity is provided with push cylinders 3 The outer wall of the push cylinder 3 is provided with threads, and the inner cavity of the inner support sleeve 2 is also correspondingly distributed with threads, and the push cylinder 3 is movably connected with the inner support sleeve 2 through the threads; The bottom of 3 is also provided with a push cylinder bottom plate, the middle of the push cylinder bottom plate is provided with a workpiece shaft through hole, and a UPE sealing ring is distributed at the workpiece shaft through hole; the above workpiece shaft through hole is set according to the size of the workpiece shaft 7 For different models and different types of workpiece shafts, the push cylinder 3 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com