Spiral type washing and detecting integrated device with free removal of oil press

An oil press, disassembly-free technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of the cumbersome process of disassembly of the oil press, hidden dangers of oil extraction quality, low cleaning efficiency, etc., to achieve convenient installation, quality assurance, Full cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

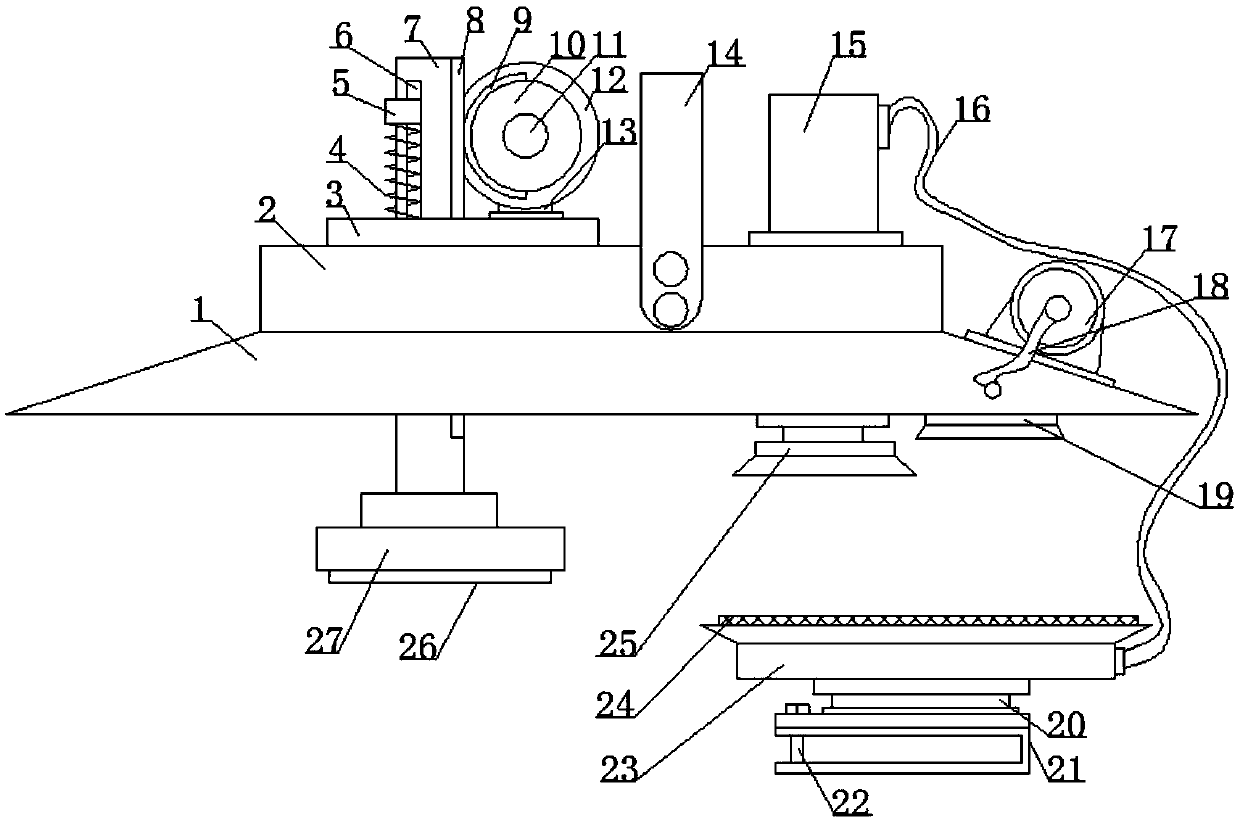

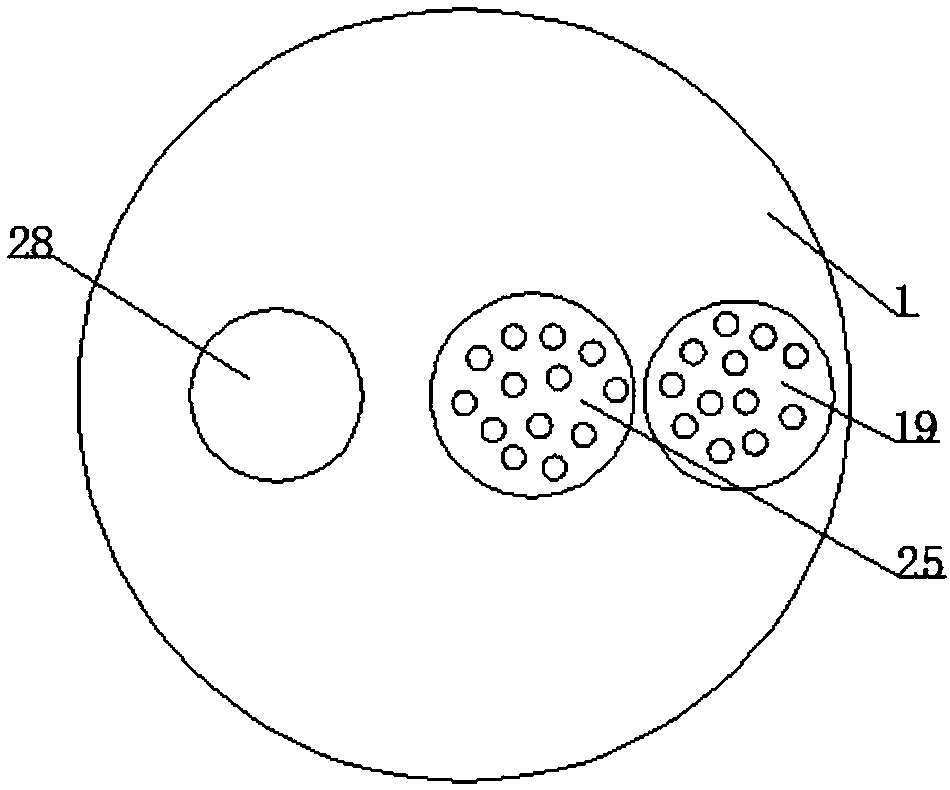

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0019] see Figure 1-2 , the present invention provides a technical solution:

[0020] A disassembly-free cleaning and detection integrated device for a screw oil press, comprising a connection box 2, a support plate 3 is fixedly installed on the left side of the upper surface of the connection box 2, and a mounting rod is fixedly installed on the right side of the upper surface of the support plate 3 13. The motor 12 is fixedly installed on the upper end of the installation rod 13, the rotating shaft 11 is installed in the middle of the motor 12, the rotating disk 10 is fixedly installed on the surface of the rotating shaft 11, and the second tooth is fixedly installed on half of the side of the rotating disk 10. Bar 9, the left side of the support plate 3 is covered with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com