Straightener for punching holes in plastic bags

A technology for plastic bags and holes, which is applied to containers, bag making operations, paper/cardboard containers, etc. It can solve the problems that the punching machine is not equipped with a straightener, the suspension of plastic bags is not neat, and the storage space is increased. Effects of stability, wear reduction, and enhanced adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

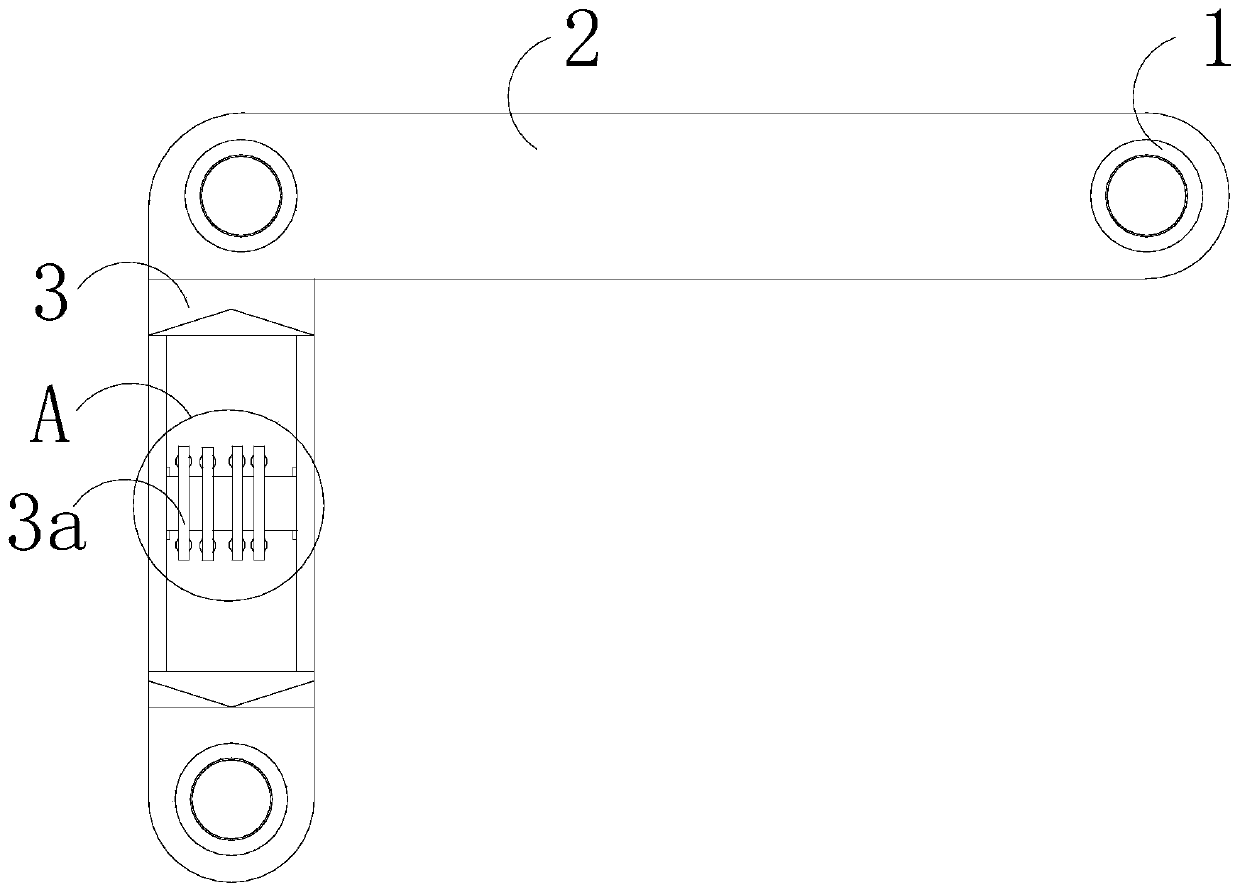

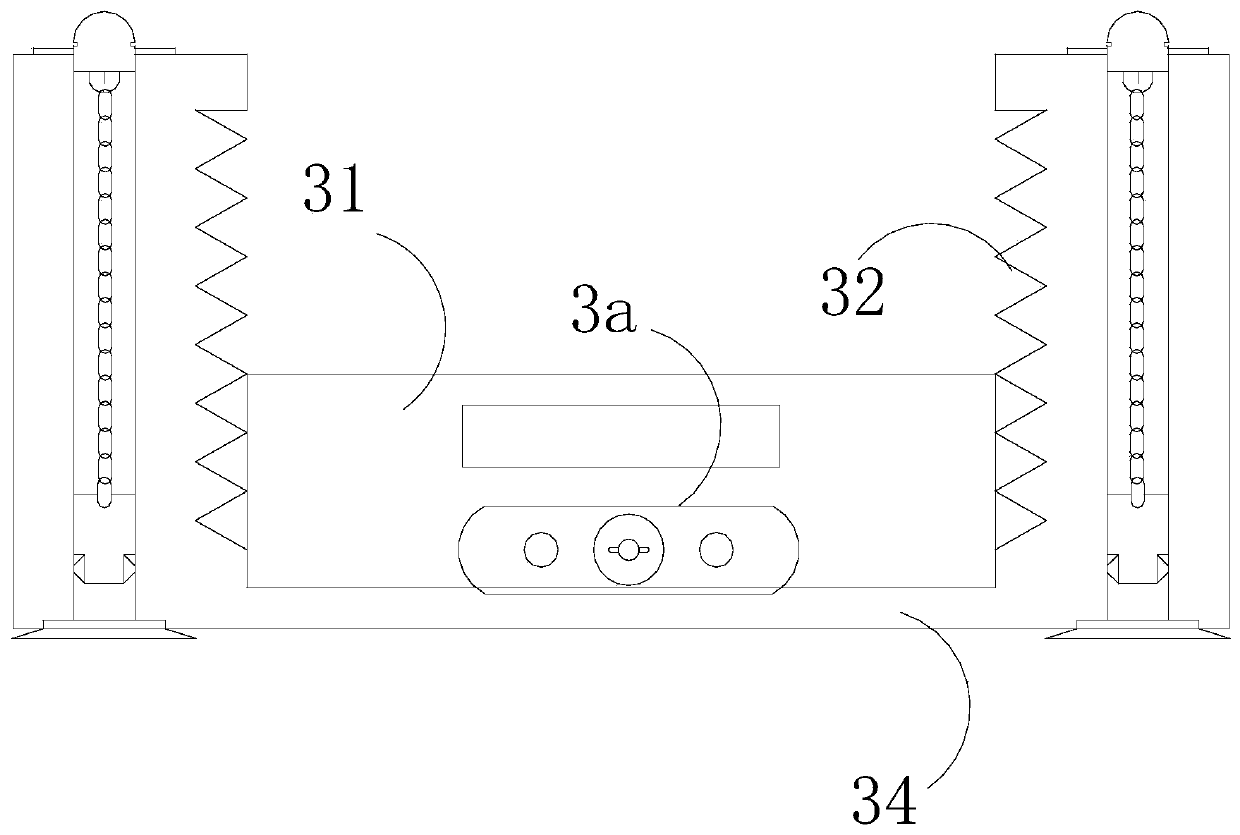

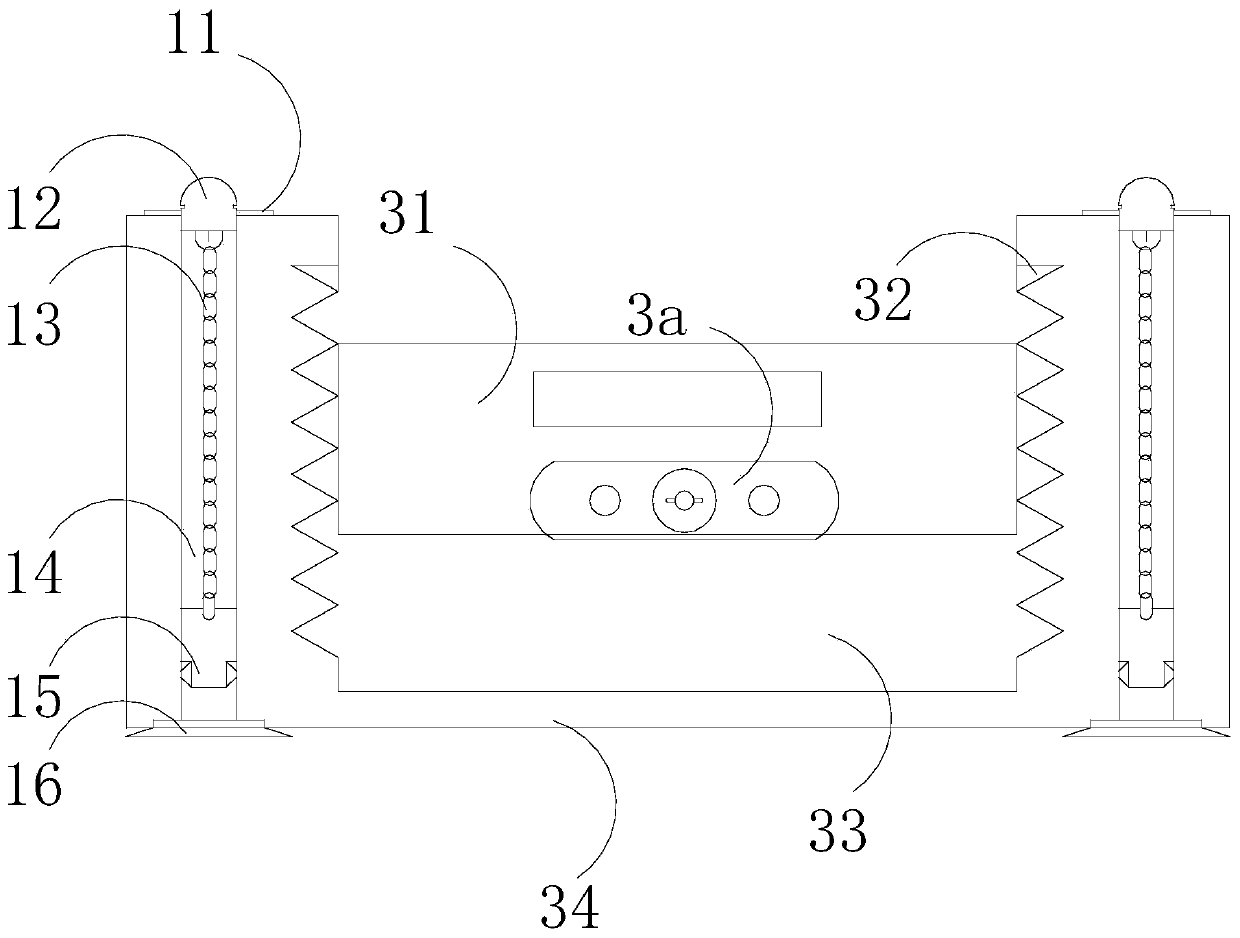

[0029] see Figure 1-Figure 7 , the present invention provides an aligner for punching plastic bags, the structure of which includes a negative pressure stabilizer 1, a calibration ruler 2, and a tension frame 3, and the calibration ruler 2 and the tension frame 3 are perpendicular to each other to form an L-shaped structure , and the inner angles of the two are right angles and the outer angles are arc angles. The length of the calibration ruler 2 is longer than that of the tension frame 3, and the calibration is not easy to be skewed when the length is long. Negative pressure stabilizers are vertically installed at both ends and turning points of the L-shaped structure. 1.

[0030] Described negative pressure stabilizer 1 is made up of backing plate 11, thread end 12, chain 13, tube channel 14, plug head 15, sucker 16, and described backing plate 11 is fixed on the upper surface of tension frame 3 or proofreading ruler 2, relatively There is a tube 14 inside the tension fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com