Screen printing nozzle device

A nozzle and screen printing technology, applied in screen printing machines, printing, printing machines, etc., can solve problems such as inability to combine and use PVDF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

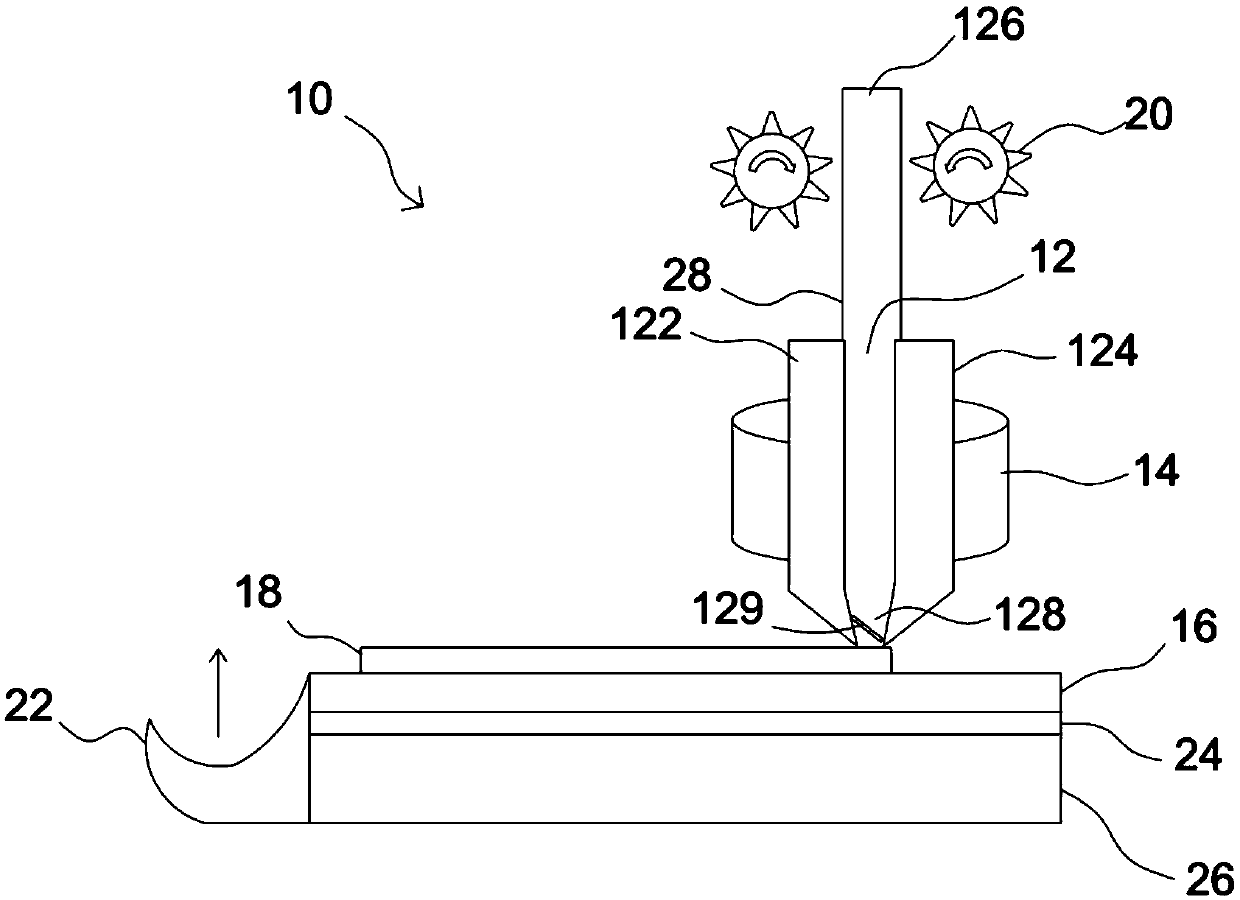

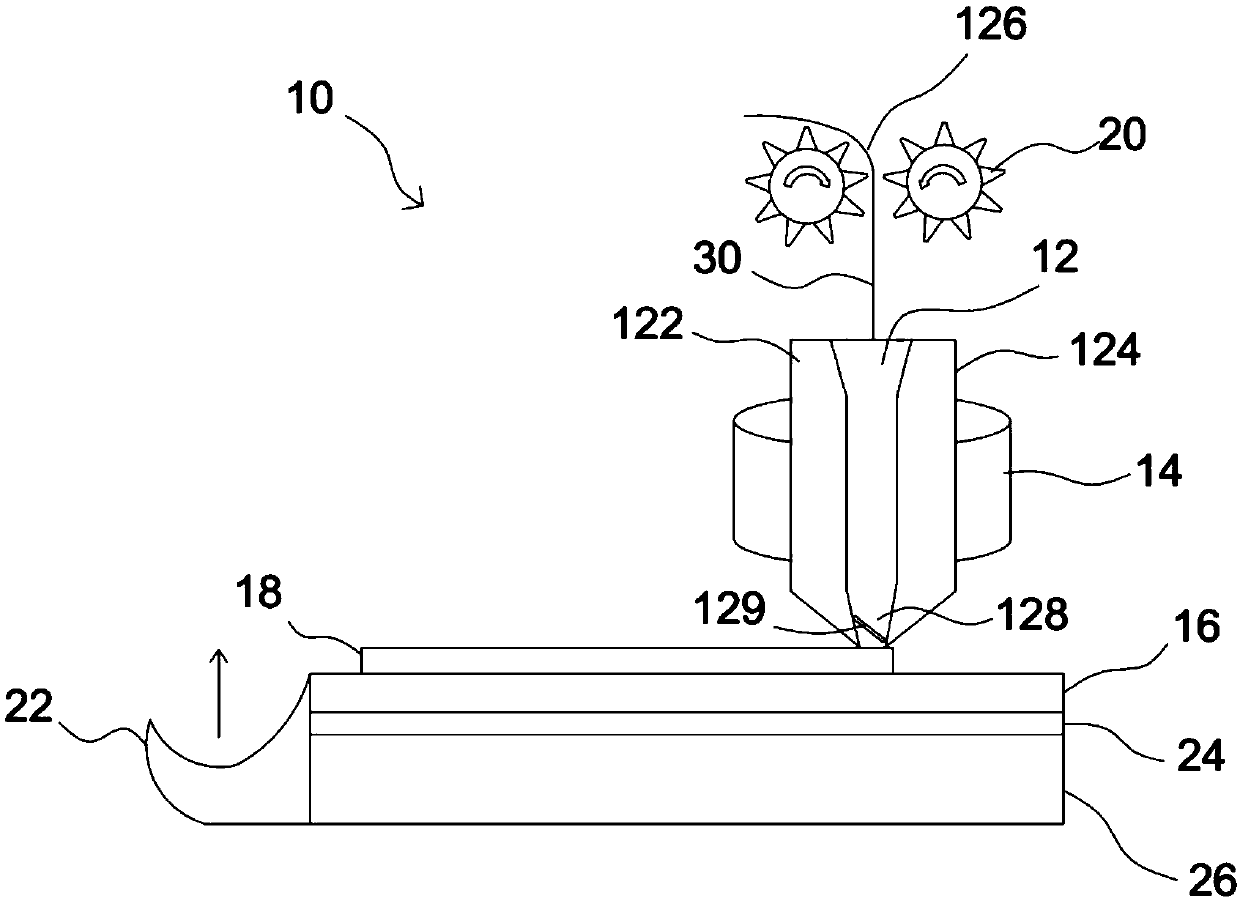

[0045] The invention provides a screen printing nozzle device, which can transfer the liquid printing material to the printed matter on the printing platform through the screen. The screen is usually a net-like material, such as cotton silk cloth and silk silk cloth. Or metal mesh, etc., and the present invention can not only be applied to general screen printing, but also can be used for film formation and polarization of plastics.

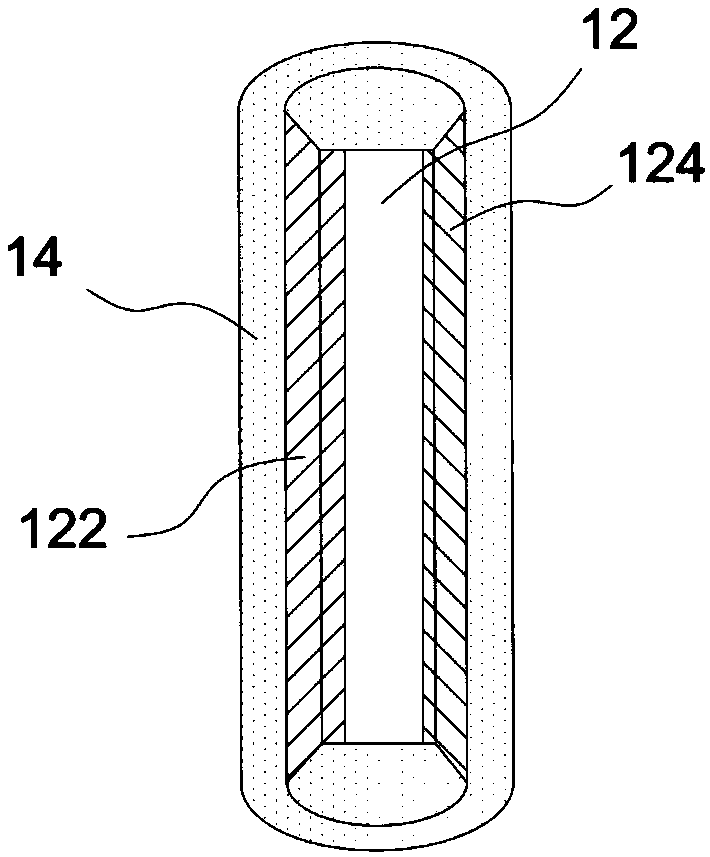

[0046] Such as figure 1 As shown, it is a schematic diagram of a first embodiment of the screen printing nozzle device of the present invention. Platform 16 and a screen plate 18, wherein scraper 122 and ink return knife 124 are relatively arranged, and the middle gap feeding of the two in the printing material is therefore equivalent to scraper 122 and ink return knife 124 and has formed injection cylinder 12, and feeding The mouth 126 is provided with a thread 28; the heater 14 is arranged on the outside of the injection cylinder 12, and in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com