Whiteboard cleaning system and method

A cleaning system and cleaning technology, applied in the direction of cleaning devices for blackboards or slates, printing, office supplies, etc., can solve the problems of taking up rest time for day-to-day students, affecting the health of teachers and students, affecting classroom efficiency, etc., to improve efficiency and save manpower , the effect of saving the time of cleaning the whiteboard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

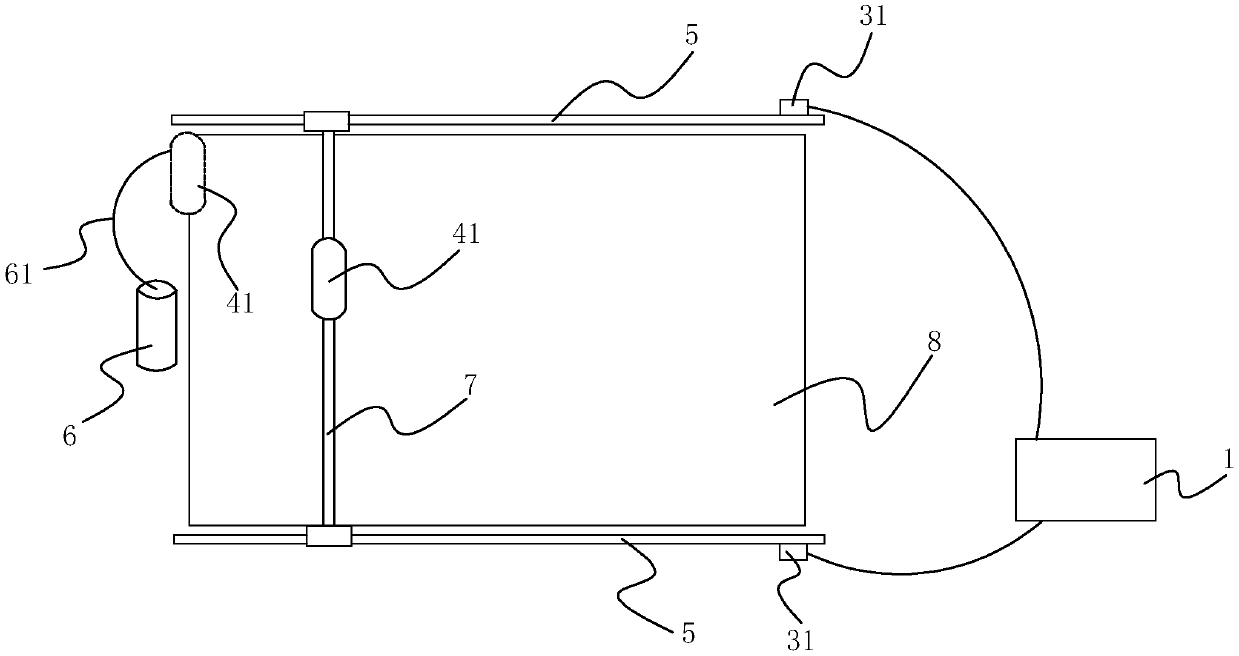

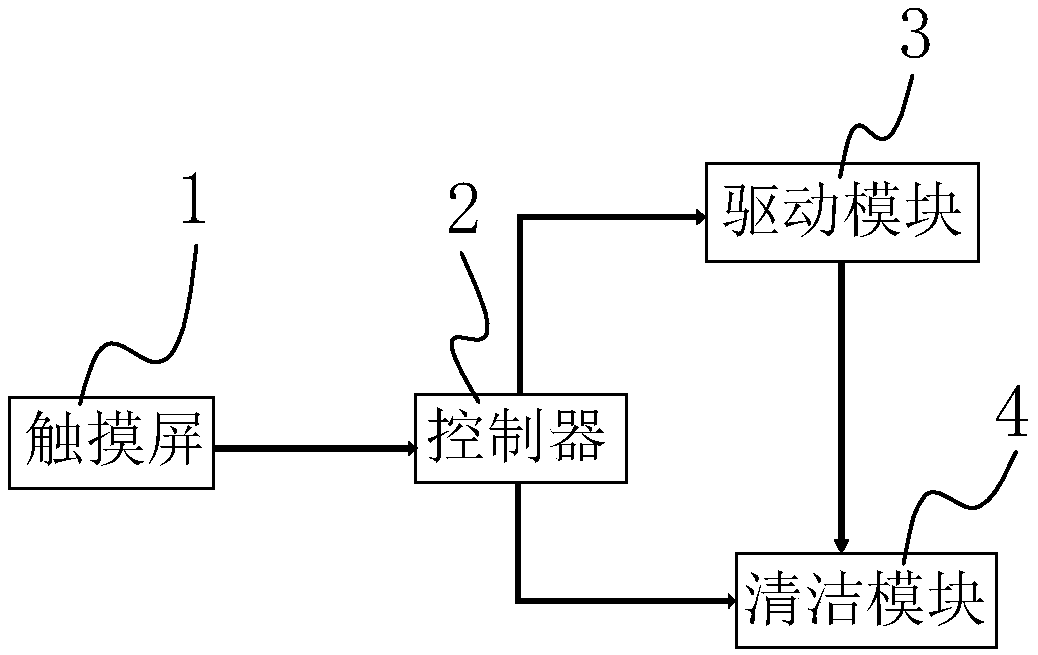

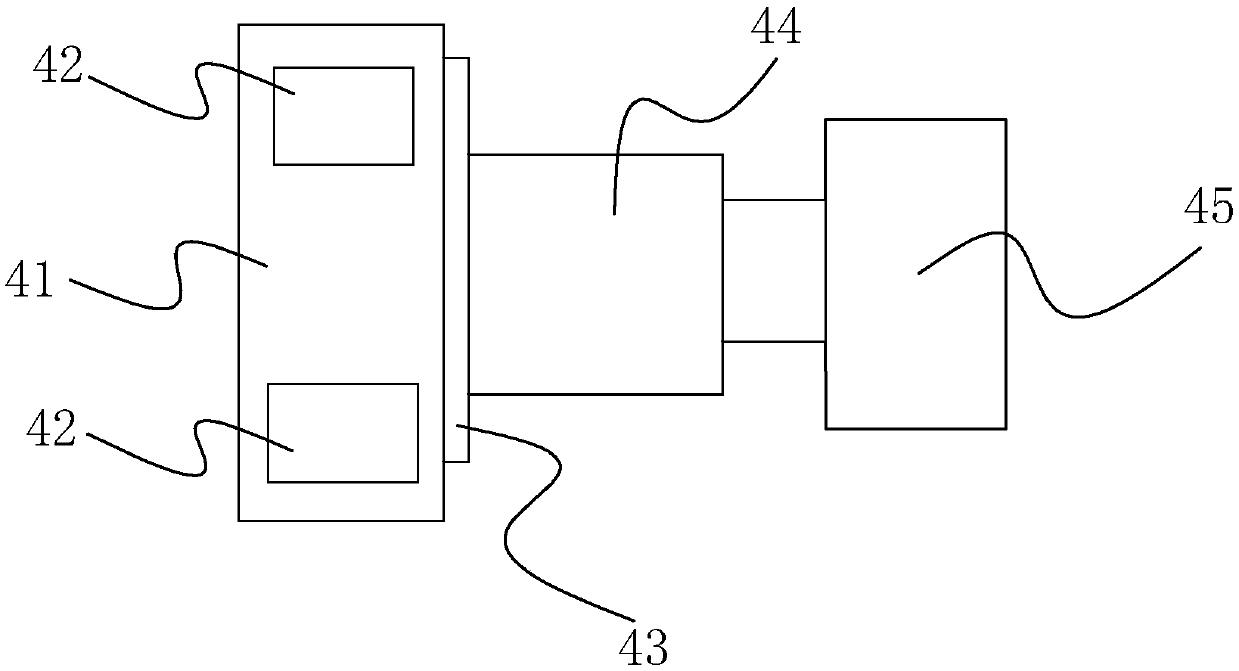

[0037] refer to figure 1 -4, Embodiment 1 of the present invention provides a whiteboard cleaning system, including a driving module 3, a cleaning module 4 and a controller 2, the driving module 3 and the cleaning module 4 are respectively connected to the controller 2, and the driving module 3 and the The cleaning module 4 is connected; it also includes a guide rail 5 and a connecting track 7, the guide rail 5 is parallel to any group of opposite sides of the whiteboard 8, the connecting track 7 is vertically connected with the guide rail 5, and the connecting track 7 is connected to the drive module 3 moves along the guide rail 5, the cleaning module 4 is connected to the connecting track 7, the cleaning module 4 moves along the connecting track 7 under the action of the driving module 3, the cleaning module 4 is provided with a wiping part, so The wiping part is in contact with the whiteboard 8 . When it is necessary to clean the whiteboard 8, the controller 2 receives the...

Embodiment 2

[0050] refer to Figure 5 , Embodiment 2 of the present invention also provides a whiteboard cleaning system, specifically, the eraser connection part includes an electric push rod 46 , and the electric push rod 46 is connected to the eraser 41 . The eraser connection part of the whiteboard cleaning system in this embodiment also includes an electric push rod 46, and the electric push rod 46 is connected with the eraser 41, mainly in order to solve the problem of removing writing on the projection screen embedded in the whiteboard 8, the projection screen Part of the board surface is lower than both sides of the board surface, so the controller 2 controls the electric push rod 46 to make the eraser 41 close to the board surface part where the whiteboard 8 is embedded, so that the board surface part where the whiteboard 8 is embedded can be cleaned quickly and effectively. Effective and practical, when the cleaning is completed, the controller 2 controls the electric push rod 4...

Embodiment 3

[0052] refer to Image 6 , Embodiment 3 of the present invention provides a whiteboard cleaning method, one of which includes but not limited to the following steps:

[0053] S1, the controller receives the trigger signal.

[0054] In this embodiment, the controller in this step will analyze the received trigger signal after receiving the trigger signal, and analyze the area of the whiteboard to be cleaned, which is the basis of the whiteboard cleaning work.

[0055] S2, the controller controls the driving module so that the connecting track moves along the guide rail, and the cleaning module moves along the connecting track, so that the cleaning module reaches the area to be cleaned.

[0056] In this embodiment, the controller in this step controls the driving module to work, the connecting track moves along the guide rail under the action of the driving module, and the cleaning module can move along the connecting track under the action of the driving module, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com