Dumper lifting safety monitoring device and method

A technology for safety monitoring and dump trucks, which is applied in the direction of signal devices and tilted vehicles, can solve the problems of poor accuracy, easy damage, large errors, etc., and achieve monitoring and management, prevention of lifting and rollover, The effect of weighing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

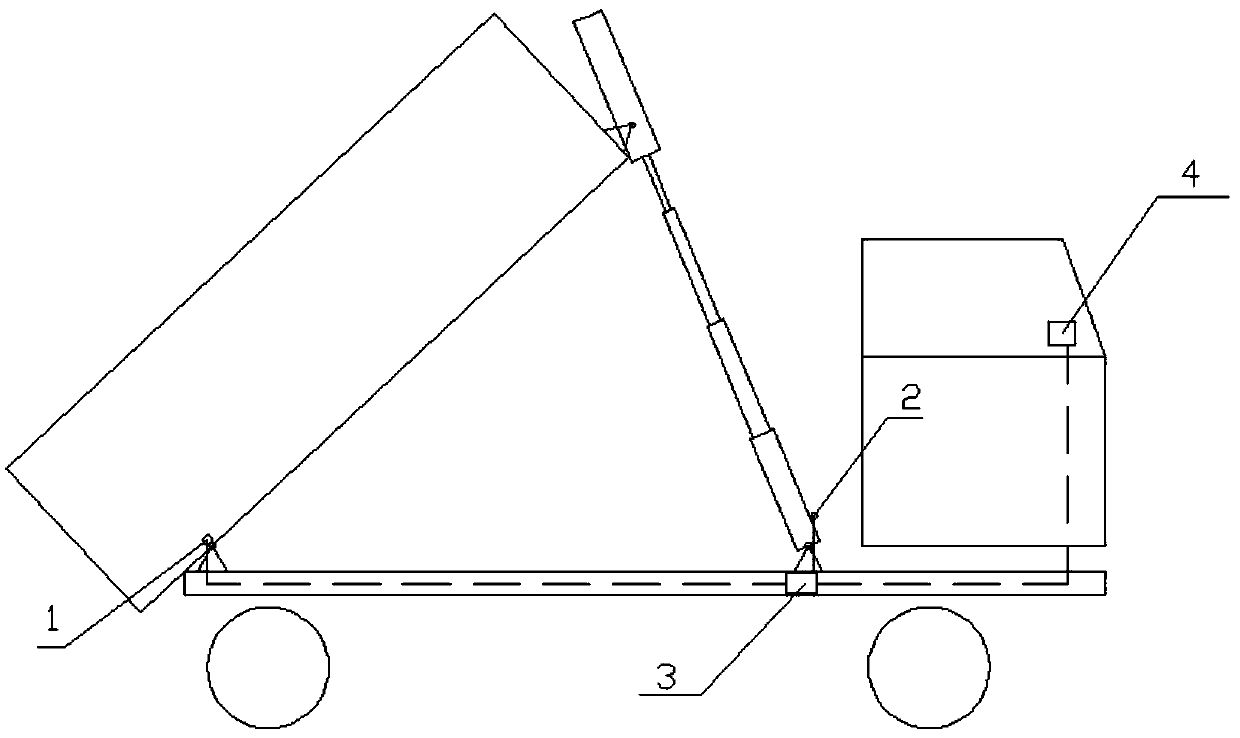

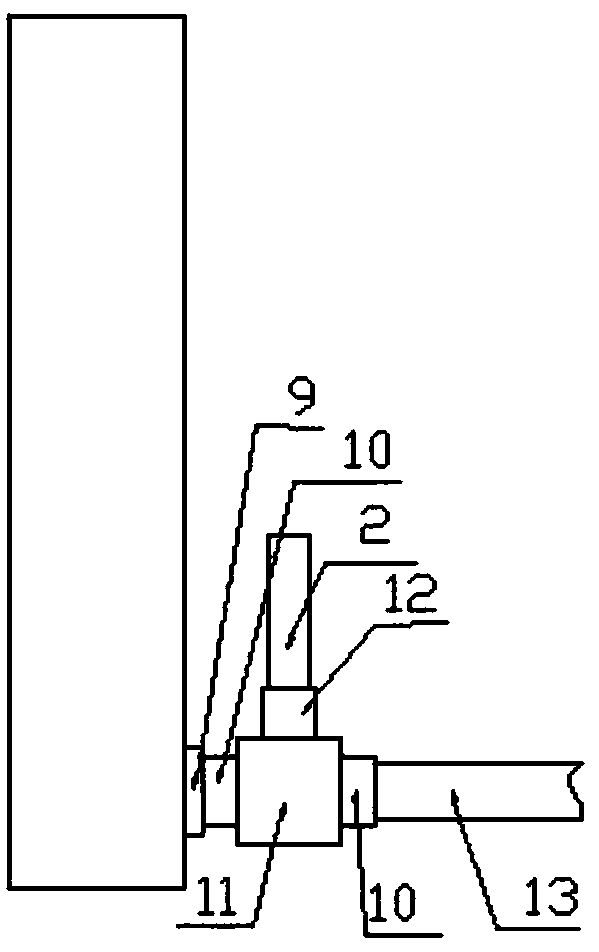

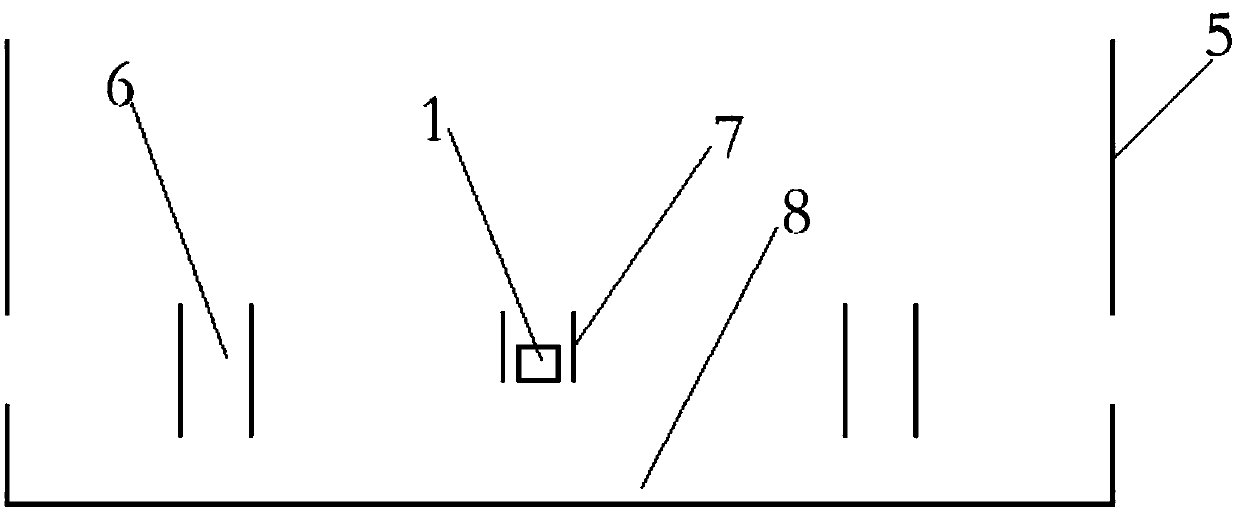

[0031] See figure 1 , 2 , 3, a dump truck lifting safety monitoring device, including four major components: angle sensor 1, oil pressure sensor 2, central control device 3, cab display device 4; angle sensor 1 is fixed to carriage 5 through angle sensor bracket 7 The bottom center position and above the turning shaft 6 and the lower cross beam 8; the angle sensor 1 collects the car lift and roll angle; the oil pressure sensor 2 is set at the oil port of the hydraulic oil cylinder, and is located between the oil inlet 9 and the oil pipe 13 The oil pressure sensor 2 is fixedly connected with the through connector 10 and the conversion connector 12 through the adapter 12, and the oil pressure sensor 2 collects the oil pressure; the angle sensor 1 and the oil pressure sensor 2 are connected to the central control thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com