PE foaming material

A foaming material and composite foaming agent technology, applied in the field of PE foaming material and its preparation, can solve problems such as poor rigidity and strength, and achieve the effect of improving rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

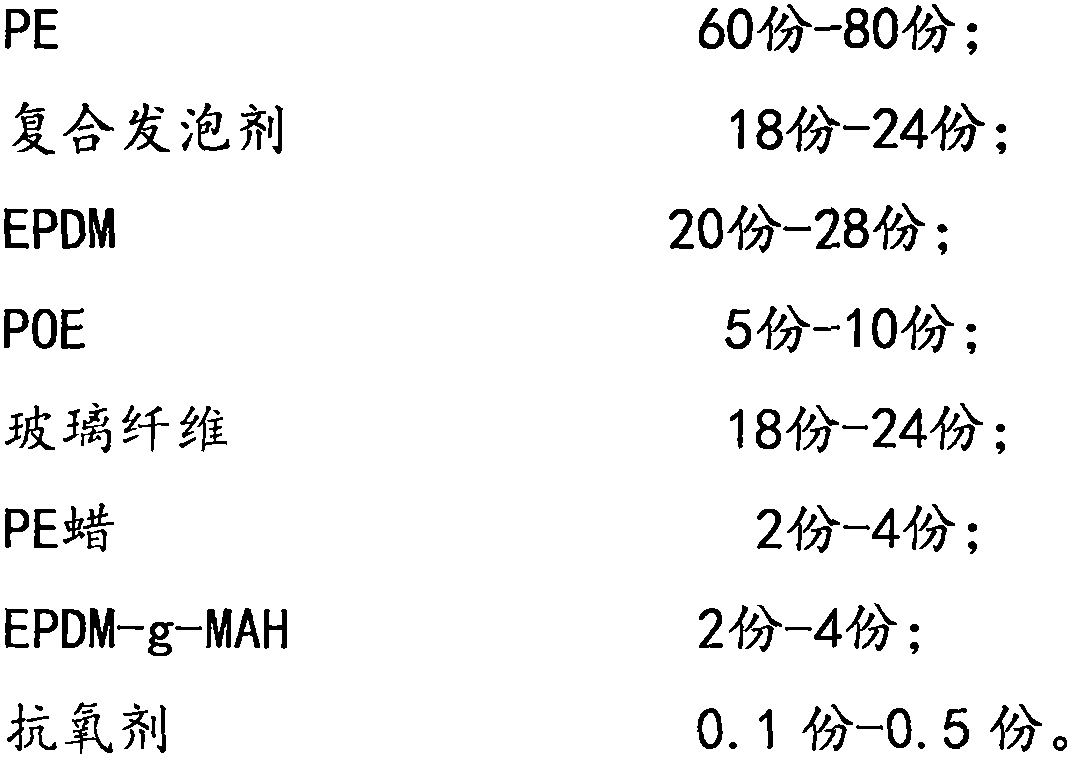

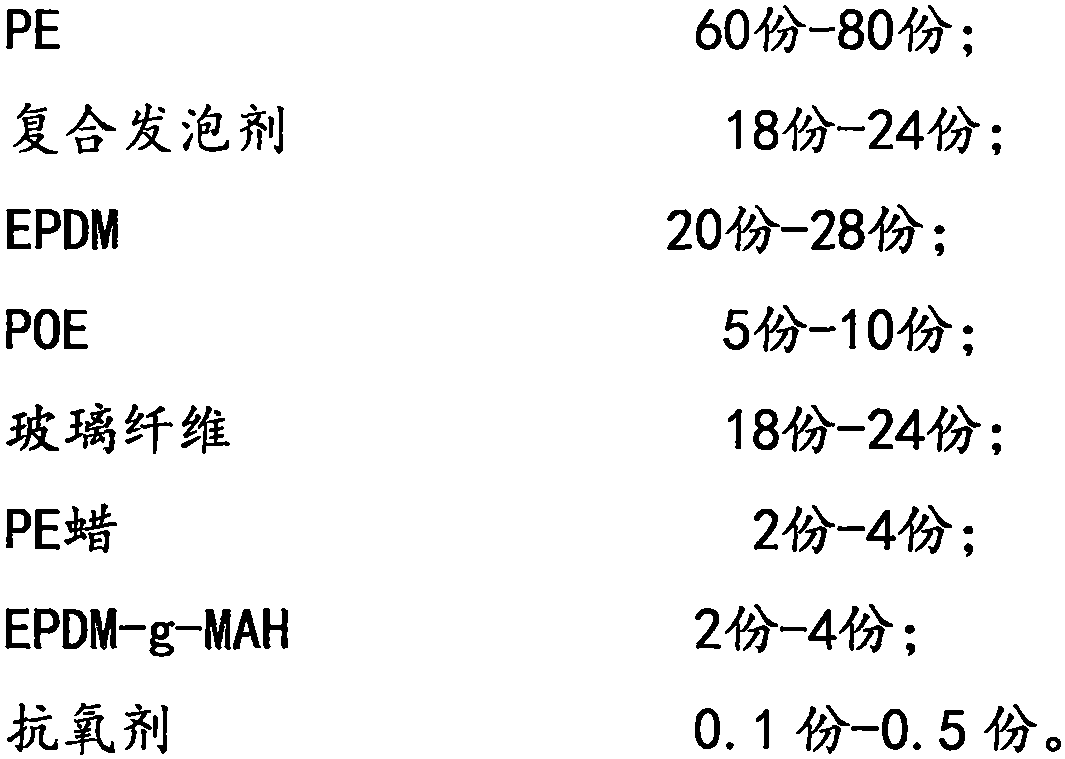

Embodiment 1

[0027] 1) Weigh 60 parts of PE, 18 parts of composite blowing agent, 20 parts of EPDM, 5 parts of POE, 18 parts of glass fiber, 2 parts of PE wax, 2 parts of EPDM-g-MAH, 0.1 part of Irganox168 and mix them evenly to obtain Mixture;

[0028] 2) Extrude and granulate the mixture obtained in step 1), to obtain PE expandable pellets P1.

[0029] 3) Distribute P1 evenly in a closed rigid mold, put it into an oven with a constant temperature of 180°C and keep it warm for 8 hours, then take it out and cool and solidify to obtain a PE foamed product.

[0030] The twin-screw extruder in step 2) includes six temperature zones arranged in sequence, the temperature in the first zone is 150°C, the temperature in the second zone is 170°C, the temperature in the third zone is 170°C, the temperature in the fourth zone is 170°C, and the temperature in the fifth zone 170°C, six zone temperature 170°C, head temperature 170°C, screw speed 200r / min.

Embodiment 2

[0032] 1) Weigh 80 parts of PE, 24 parts of composite blowing agent, 28 parts of EPDM, 10 parts of POE, 24 parts of glass fiber, 4 parts of PE wax, 4 parts of EPDM-g-MAH, 0.2 parts of Irganox1010, 0.2 parts of Irganox1330, 0.1 Parts of Irganox168 are mixed and stirred evenly to obtain a mixture;

[0033] 2) Extrude and granulate the mixture obtained in step (1) to obtain PE expandable pellets P2.

[0034] 3) Distribute P2 evenly in a closed rigid mold, put it in an oven with a constant temperature of 190°C for 12 hours, take it out and cool and solidify to obtain a PE foamed product.

[0035] The twin-screw extruder in step 2) includes six temperature zones arranged in sequence, the temperature of the first zone is 170°C, the temperature of the second zone is 190°C, the temperature of the third zone is 190°C, the temperature of the fourth zone is 190°C, and the temperature of the fifth zone is 190°C , the six-zone temperature is 190°C, the head temperature is 190°C, and the s...

Embodiment 3

[0037] 1) Weigh 70 parts of PE, 21 parts of composite blowing agent, 24 parts of EPDM, 8 parts of POE, 21 parts of glass fiber, 3 parts of PE wax, 3 parts of EPDM-g-MAH, 0.2 part of Irganox1010, 0.1 part of Irganox1330 and mix them Stir evenly to obtain a mixture;

[0038] 2) extrude the mixture obtained in step 1) to obtain PE expandable pellets P3.

[0039] 3) Distribute P3 evenly in a closed rigid mold, put it into an oven with a constant temperature of 185°C and keep it warm for 10 hours, then take it out and cool and solidify to obtain a PE foamed product.

[0040] The twin-screw extruder in step 2) includes six temperature zones arranged in sequence, the temperature of the first zone is 160°C, the temperature of the second zone is 180°C, the temperature of the third zone is 180°C, the temperature of the fourth zone is 180°C, and the temperature of the fifth zone is 180°C , the temperature in the six zones is 180°C, the head temperature is 180°C, and the screw speed is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com