Trace-type light cable bridge frame

A technology of cable trays and concave points, which is applied in the field of trace-type lightweight cable trays, can solve the problems of metal plate thickness, self-weight, and low strength, and achieve the effects of increasing strength and rigidity, reducing self-weight, and reducing bridge costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

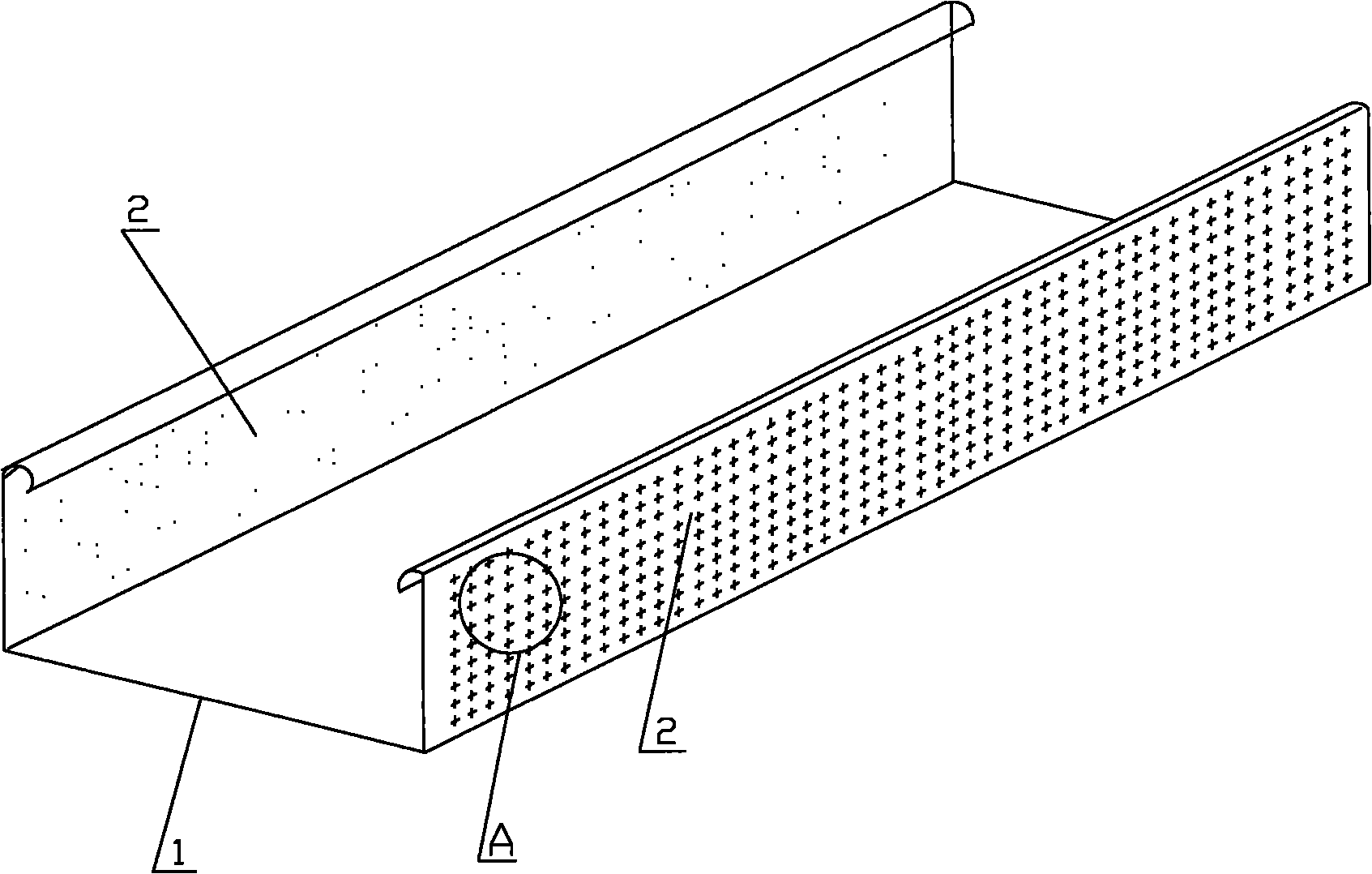

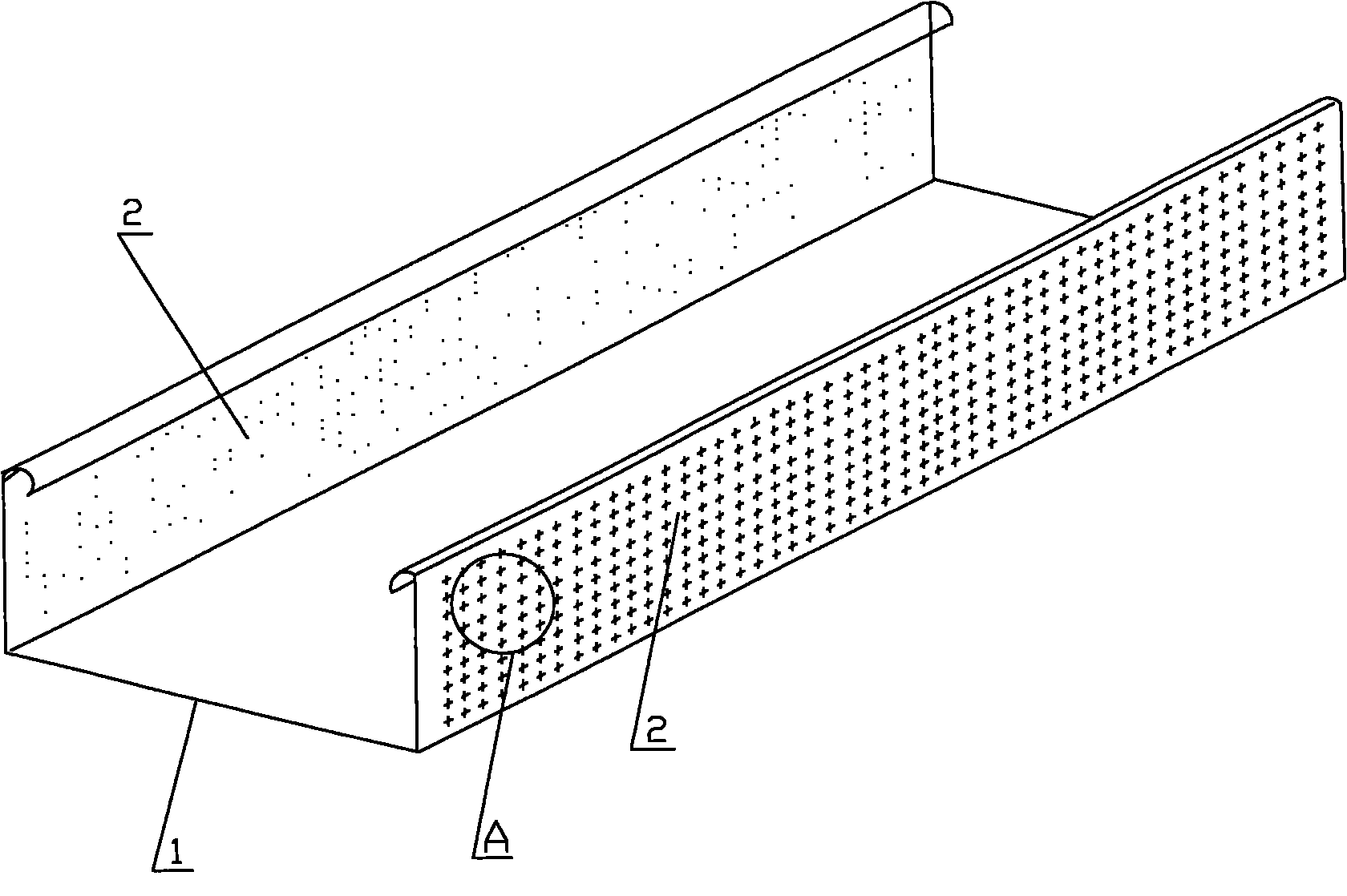

[0016] A cable tray is composed of a bottom plate 1 and a side plate 2, the two sides of the bottom plate 1 are respectively fixed on the inside of the lower bottom of the two side plates 2, and the characteristic is that the bottom plate or the side plate is provided with a concave point 3.

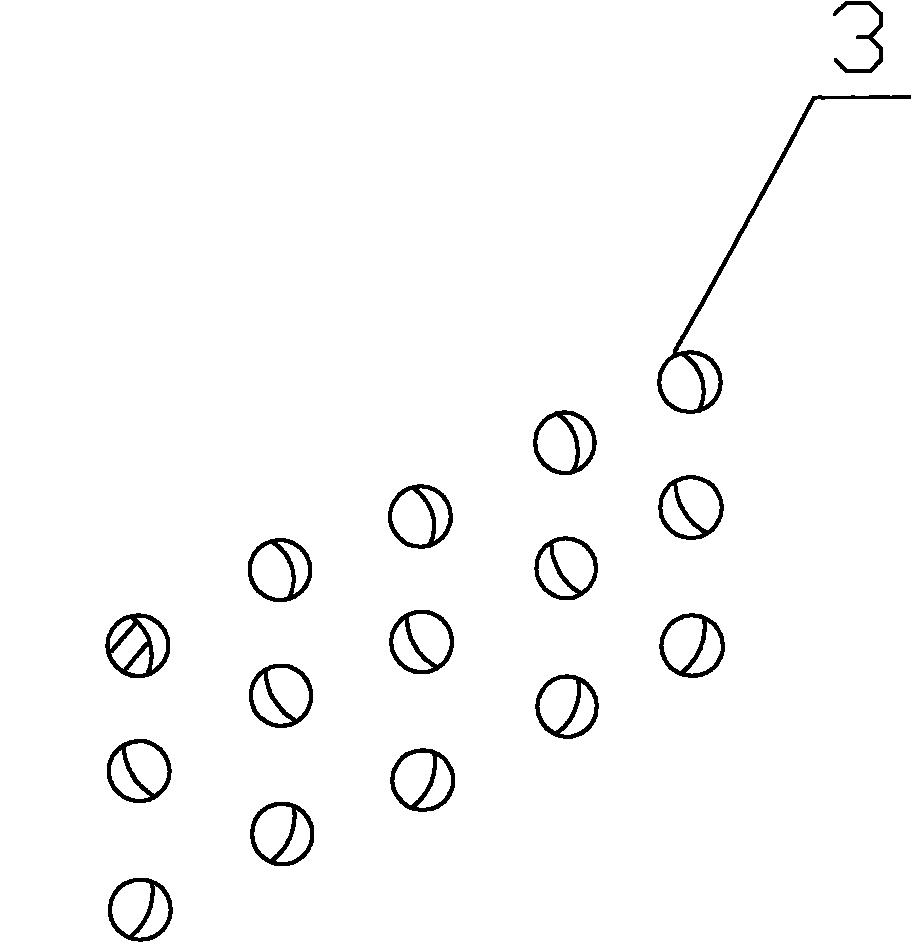

[0017] The size of the pit on the bottom plate or side plate of the cable tray is 1.5mm and the depth is 0.5mm.

[0018] The cross-section of the pits is circular, and the pits are distributed in a diamond shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com