Washing machine

A washing machine, in-line technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve problems such as collision with outer walls, drying buckets or damage to outer walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A washing machine, comprising: an outer casing, an inner cylinder is arranged in the outer casing, and a buffer member is arranged between the inner cylinder and the inner side of the outer casing.

[0027] The buffer member includes a bracket. One end of the bracket is in-line and connected to the inner wall of the shell; the other end of the bracket is a buffer wheel bayonet, and a buffer wheel is installed in the buffer wheel bayonet.

[0028] The buffer members are in two rows.

[0029] There are two buffer members in each row.

[0030] The buffer wheel bayonet is a C-shaped structure.

[0031] The buffer wheel is an elastic rubber wheel.

[0032] The buffer wheel is attached to the outside of the inner cylinder.

[0033] A dark groove with a door is arranged on the shell, and a counterweight is arranged in the dark groove.

[0034] The lower part of the inner cylinder and the lowermost part of the shell are provided with a water collection tank.

[0035] A dra...

Embodiment 2

[0037] The difference from Example 1: the buffer wheel is a hard wheel and a flat wheel.

Embodiment 3

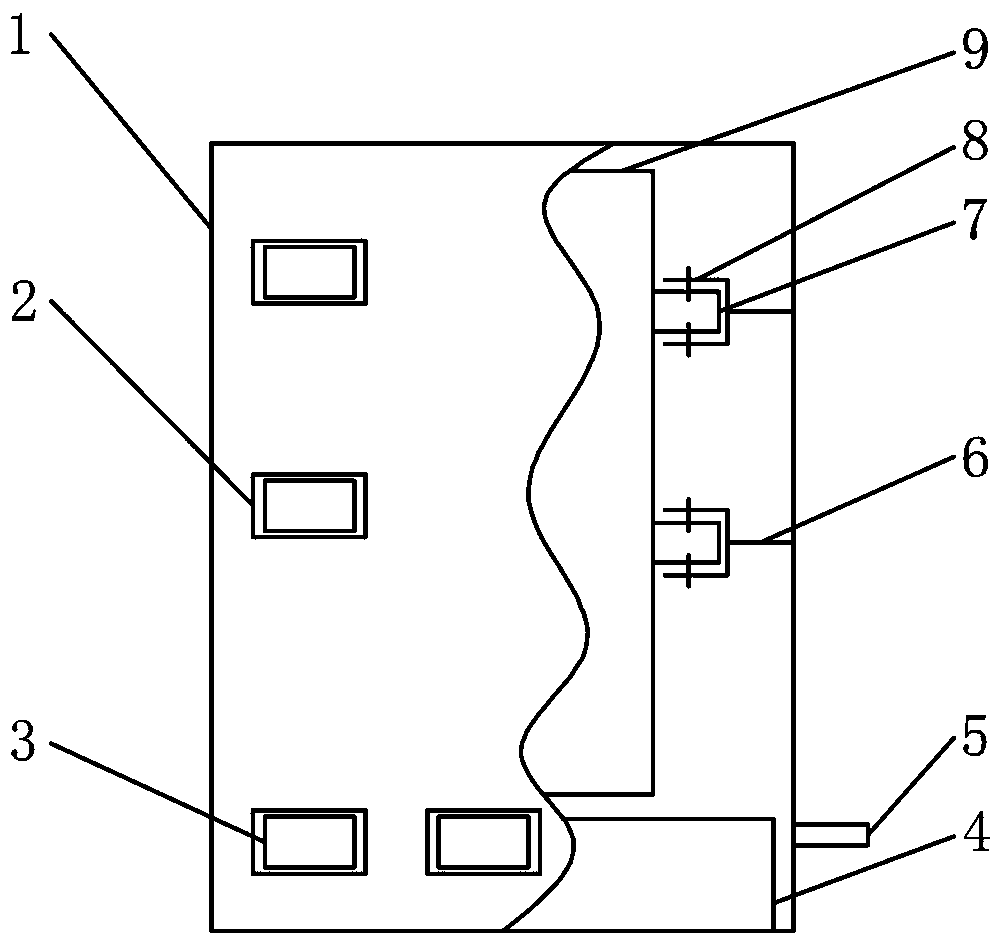

[0039] A washing machine, comprising: a casing 1, an inner cylinder 9 is arranged inside the casing, and a buffer member 6 is arranged between the inner cylinder and the inner side of the casing.

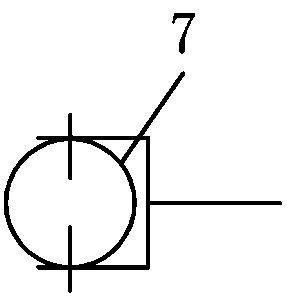

[0040] The buffer includes a bracket. One end of the bracket is in-line and connected to the inner wall of the shell; the other end of the bracket is a buffer wheel bayonet 8, and a buffer wheel 7 is installed in the buffer wheel bayonet.

[0041] The buffer members are in two rows.

[0042] There are two buffer members in each row.

[0043] The buffer wheel bayonet is a C-shaped structure.

[0044] The buffer wheel is an elastic rubber wheel and is a circular wheel.

[0045] The buffer wheel is attached to the outside of the inner cylinder.

[0046] The shell 1 is provided with a dark groove 2 with a door, and a counterweight 3 is arranged in the dark groove.

[0047] The lower part of the inner cylinder and the lowermost part of the shell are provided with a sump 4 .

[0048]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com