Box girder mobile-type whole-hole cast-in-situ equipment and using method thereof

A mobile, box girder technology, applied in bridge construction, bridges, erection/assembly of bridges, etc., can solve the problems of inability to meet the construction period requirements of the Yinxi project, complex construction techniques, and high costs, and achieve low construction risks, The effect of simple construction process and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

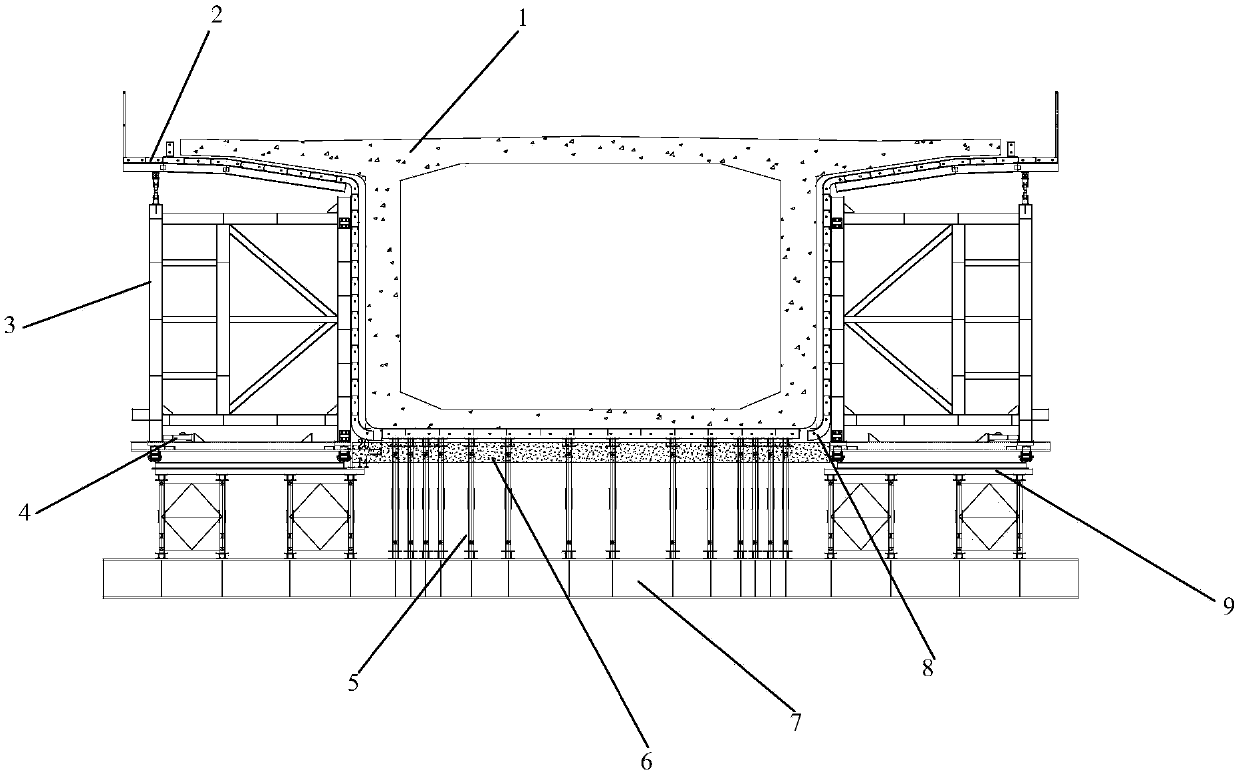

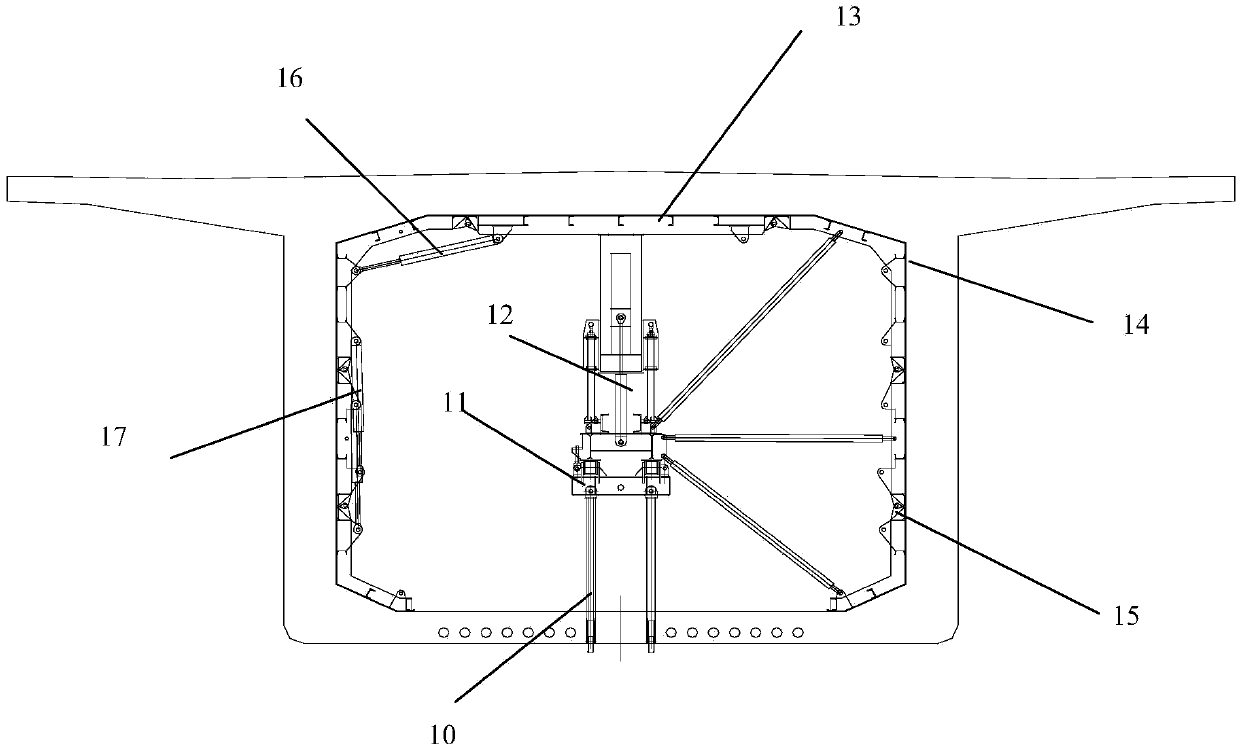

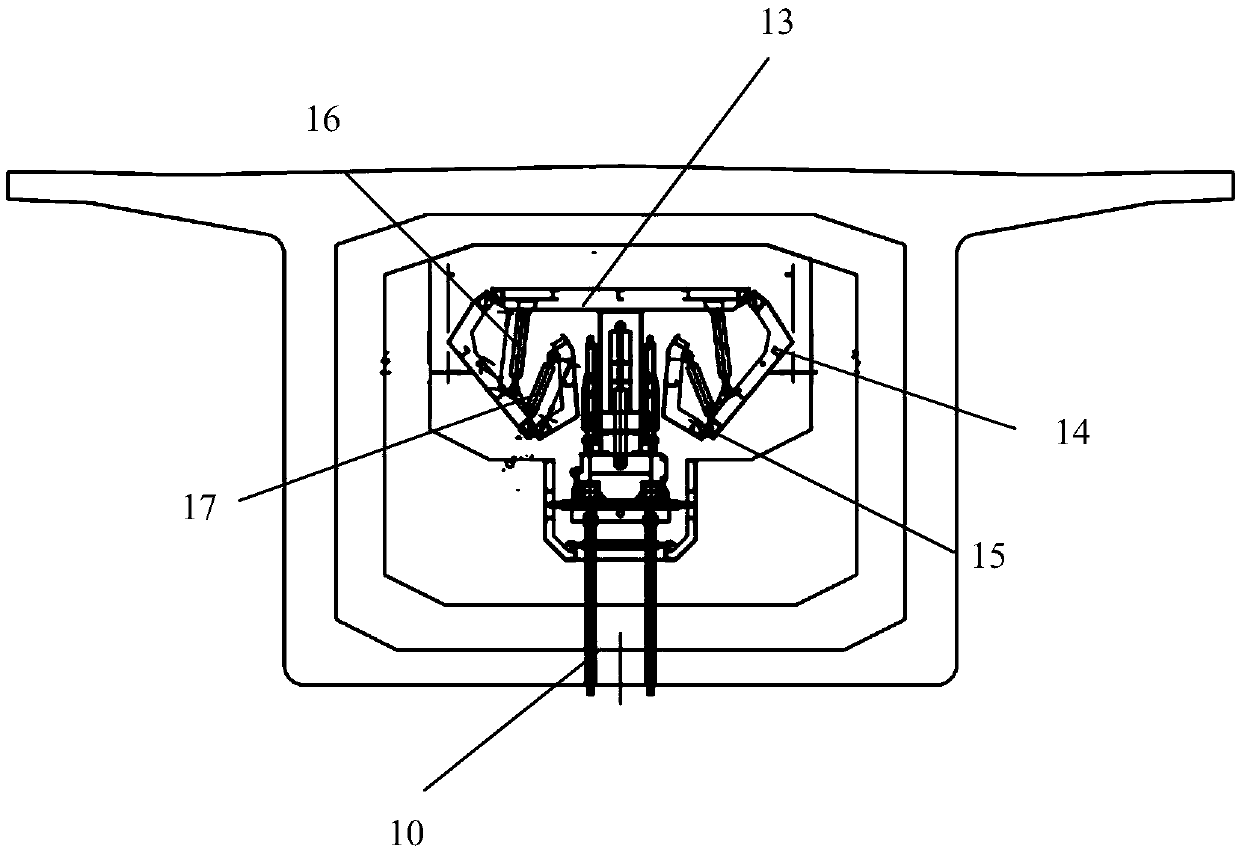

[0030] See figure 1 and figure 2 , figure 1 It is a schematic structural diagram of the outer mold of the box girder movable whole-hole cast-in-situ equipment provided by the present invention.

[0031] The embodiment of the present invention provides a box girder mobile whole-hole cast-in-situ equipment. The box girder mobile whole-hole cast-in-place equipment includes a beret beam 7, which is equipped on the upper part of the bridge pier and temporary pier. The beam body provides a working place for the pouring construction of the box beam 1, and a rail 9 is installed on the Bailey beam 7 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com